Polyamide-6 colored granula and preparation method thereof

A manufacturing method and slicing technology, which is applied in the field of nylon, can solve the problems of R&D or production of colored chips that have not been seen, and achieve the effect of long life and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

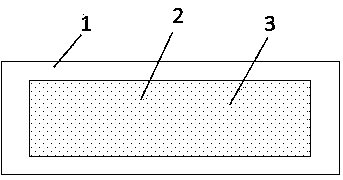

[0025] Such as figure 1 As shown, the present invention provides a nylon 6 colored slice, comprising: an outer layer 1, an inner layer 2, and colored particles 3, the outer layer 1 and the inner layer 2 are closely connected, and the colored particles 3 are in the inner layer 2.

[0026] Wherein, the inner layer 2 is red nylon 6 slices.

[0027] Wherein, the outer layer 1 is nylon 6 slices.

[0028] Wherein, the colored particles 3 are red particles.

[0029] Wherein, the ratio range of the cross-sectional diameters of the outer layer 1 and the inner layer 2 is 1:2.

[0030] Wherein, the cross-section of the slice is rectangular.

[0031] Wherein, the percentage range of the mass of the colored particles 3 to the mass of the inner layer 2 is 0.02%.

[0032] The present invention also provides a method for manufacturing nylon 6 colored slices, the steps are as follows:

[0033] 1) The coloring agent, nylon 6 slices and dispersant are proportioned; the coloring agent is red...

Embodiment 2

[0039] Such as figure 1 As shown, the present invention provides a nylon 6 colored slice, comprising: an outer layer 1, an inner layer 2, and colored particles 3, the outer layer 1 and the inner layer 2 are closely connected, and the colored particles 3 are in the inner layer 2.

[0040] Wherein, the inner layer 2 is blue nylon 6 slices.

[0041] Wherein, the outer layer 1 is nylon 6 slices.

[0042] Wherein, the colored particles 3 are blue particles.

[0043] Wherein, the ratio of the cross-sectional diameters of the outer layer 1 to the inner layer 2 is 8:1.

[0044] Wherein, the cross-section of the slice is circular.

[0045] Wherein, the mass of the colored particles 3 accounts for 5% of the mass of the inner layer.

[0046] The present invention also provides a method for manufacturing nylon 6 colored slices, the steps are as follows:

[0047] 1) The colorant, nylon 6 slices and dispersant are proportioned; the colorant is blue particles, the dispersant is fatty ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com