Spin friction welding structure assembly, internal combustion engine cylinder cover provided with structure assembly, cylinder cover and cylinder body alloying part and mechanical device

A technology of rotational friction welding and structural components, which is applied in the direction of cylinder heads, mechanical equipment, machines/engines, etc. It can solve the problem of affecting the quality of friction welding, the extrudates cannot be completely, quickly, smoothly and completely discharged from the welding interface, and the extrudates are timely Problems such as poor drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

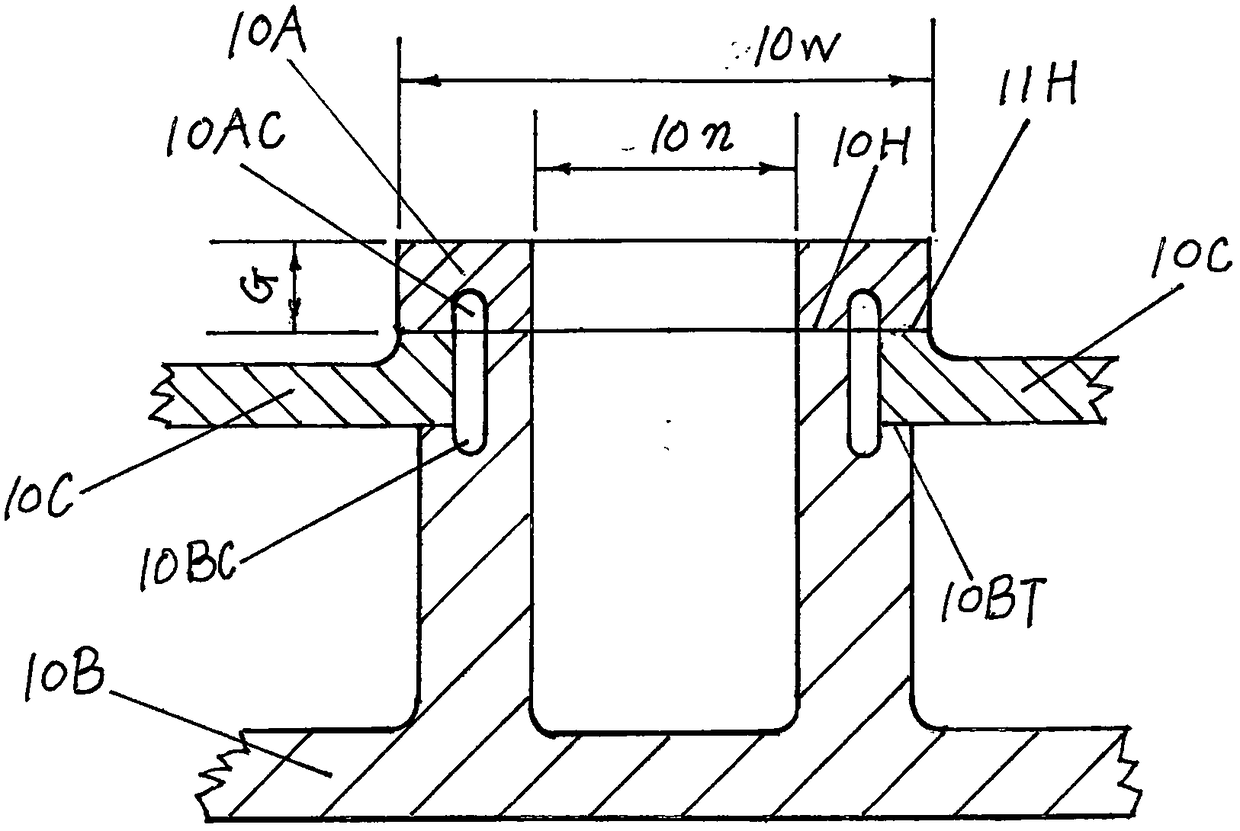

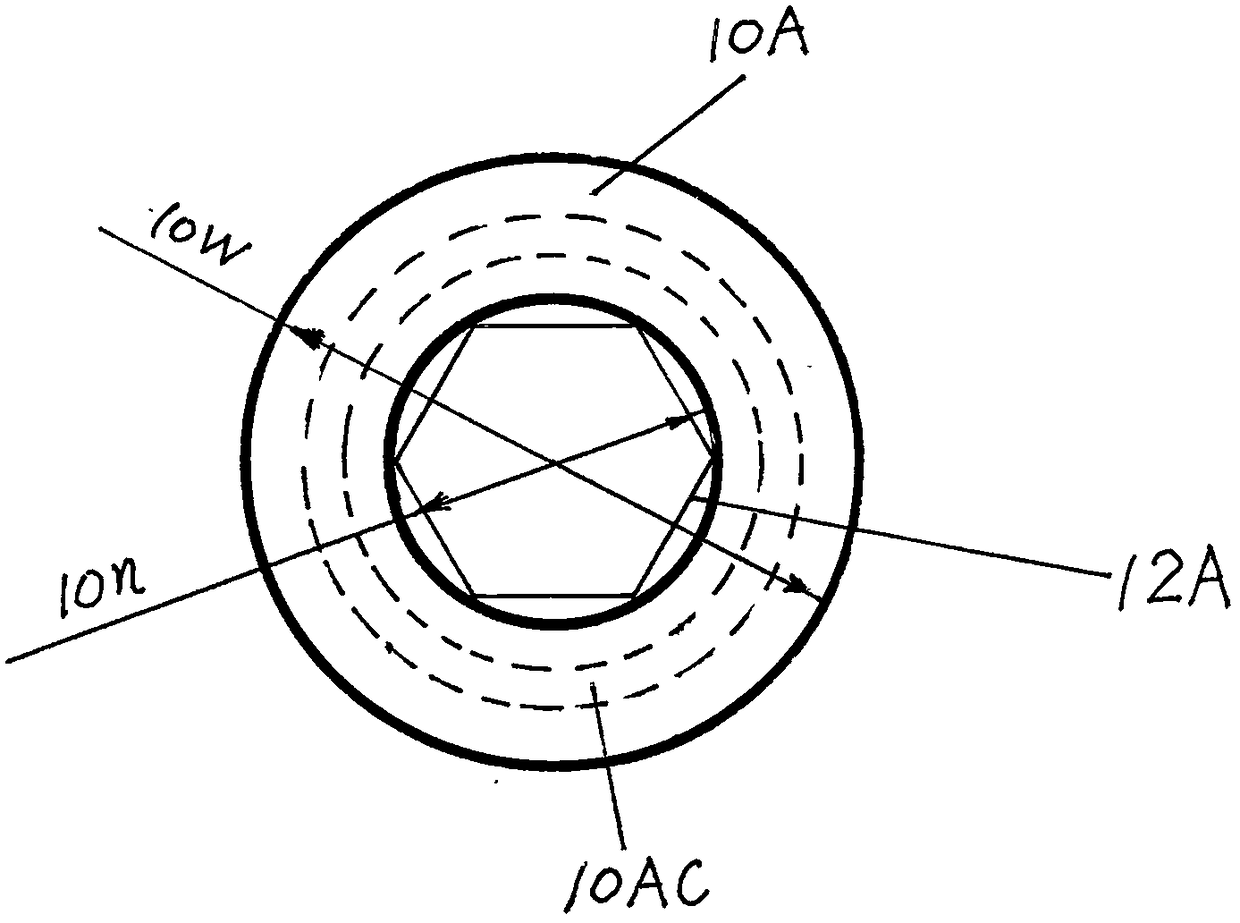

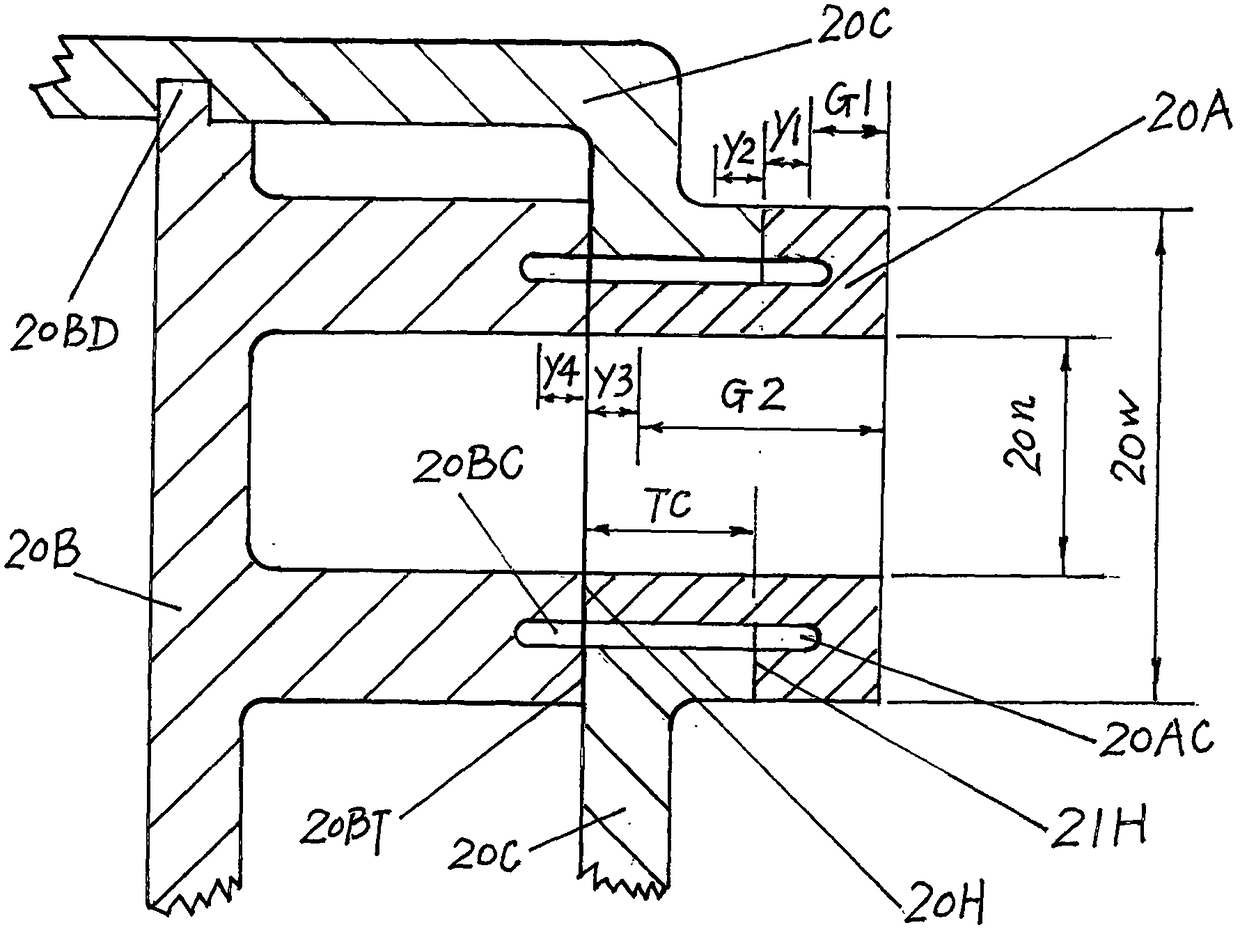

[0018] figure 1 : An embodiment of a rotational friction welding structural assembly formed by axially assembling the joints of the openings of the first workpiece and the second workpiece. The supporting surface 10BT of the first workpiece 10B supports the second workpiece 10C, and the rotary friction welding orifice connecting ring 10A rotates under the pressure of pressing the first welding interface 10H and the second welding interface 11H. As the temperature rises, the second welding interface The material at the first welding interface 10H and the second welding interface 11H is softened and pushed out of the first welding interface 10H and the second welding interface 11H, the rotation is stopped, the workpiece is cooled under pressure, and the friction welding is completed. In addition to flowing into the orifice gap between the first workpiece and the second workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com