Giant magnetostictive ultrasonic spindle

A technology of giant magnetostriction and giant magnetostrictive rods, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve problems such as heat generation, and achieve the effect of solving heat generation and improving power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

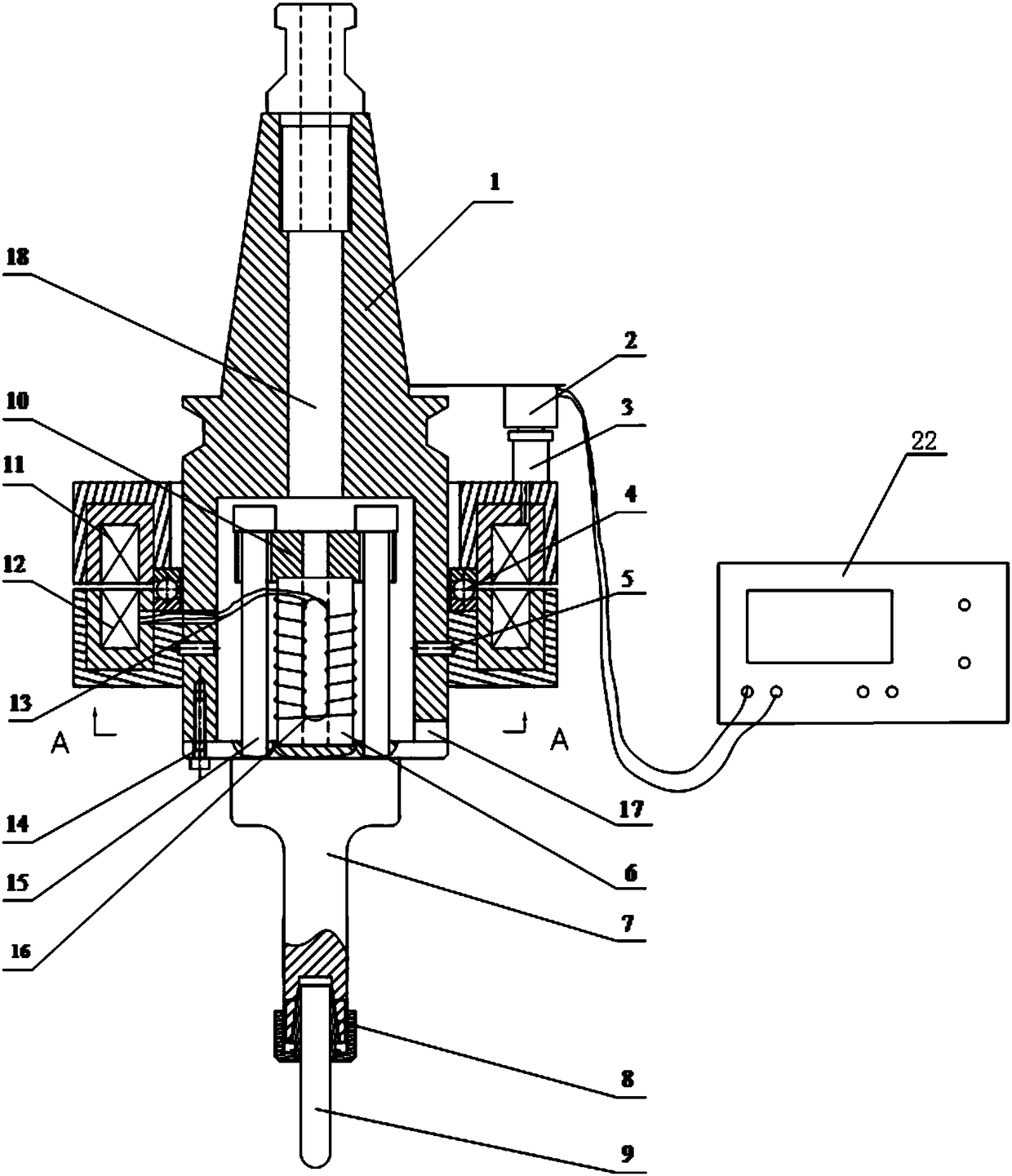

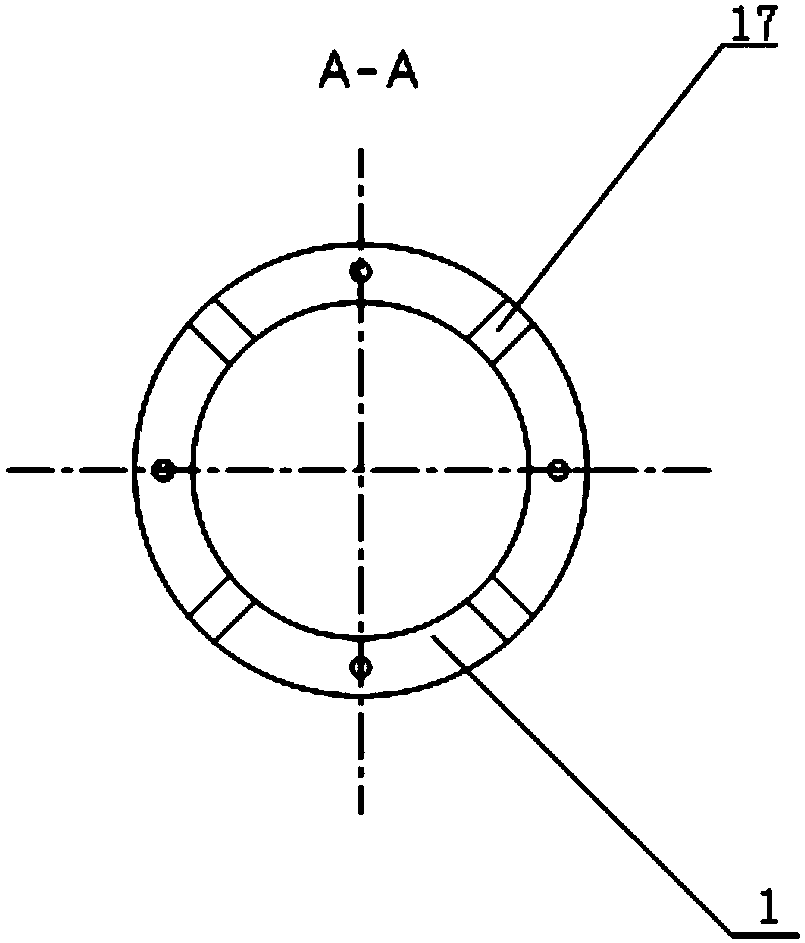

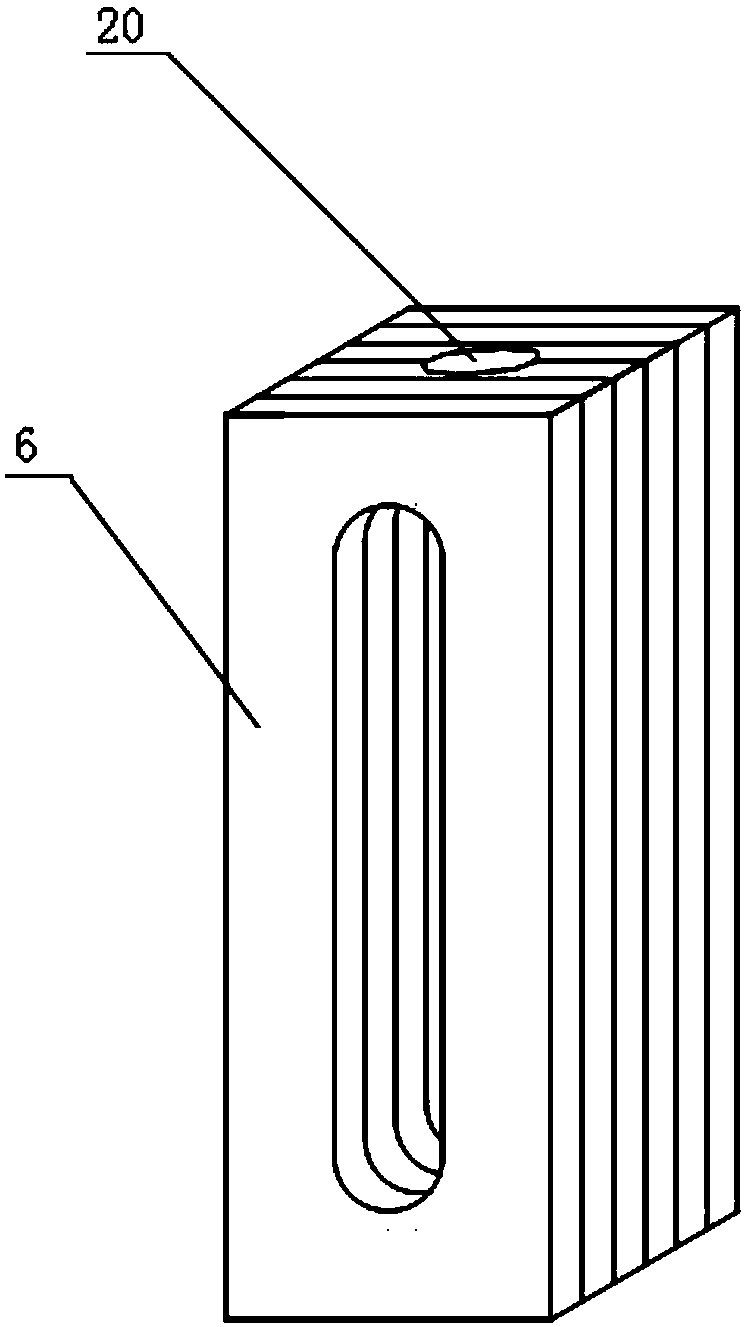

[0023] The giant magnetostrictive ultrasonic spindle of the present invention, such as figure 1 As shown, including the handle 1, the handle 1 is provided with a through hole a18 axially, and the lower end of the handle 1 is also provided with an air outlet 17, and the distribution of the air outlet 17 is as follows figure 2 As shown, the lower part of the knife handle 1 has an accommodating cavity, and the accommodating cavity communicates with the through hole a18 and the air outlet 17. A back cover 10 is arranged in the accommodating cavity, and there is a gap between the back cover 10 and the knife handle. gap, the rear cover 10 is connected to the horn 7 through the pre-tightening bolt 15, the upper end of the horn 7 is connected to the lower end of the handle 1, and the lower end of the horn 7 is connected to the tool head 9. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com