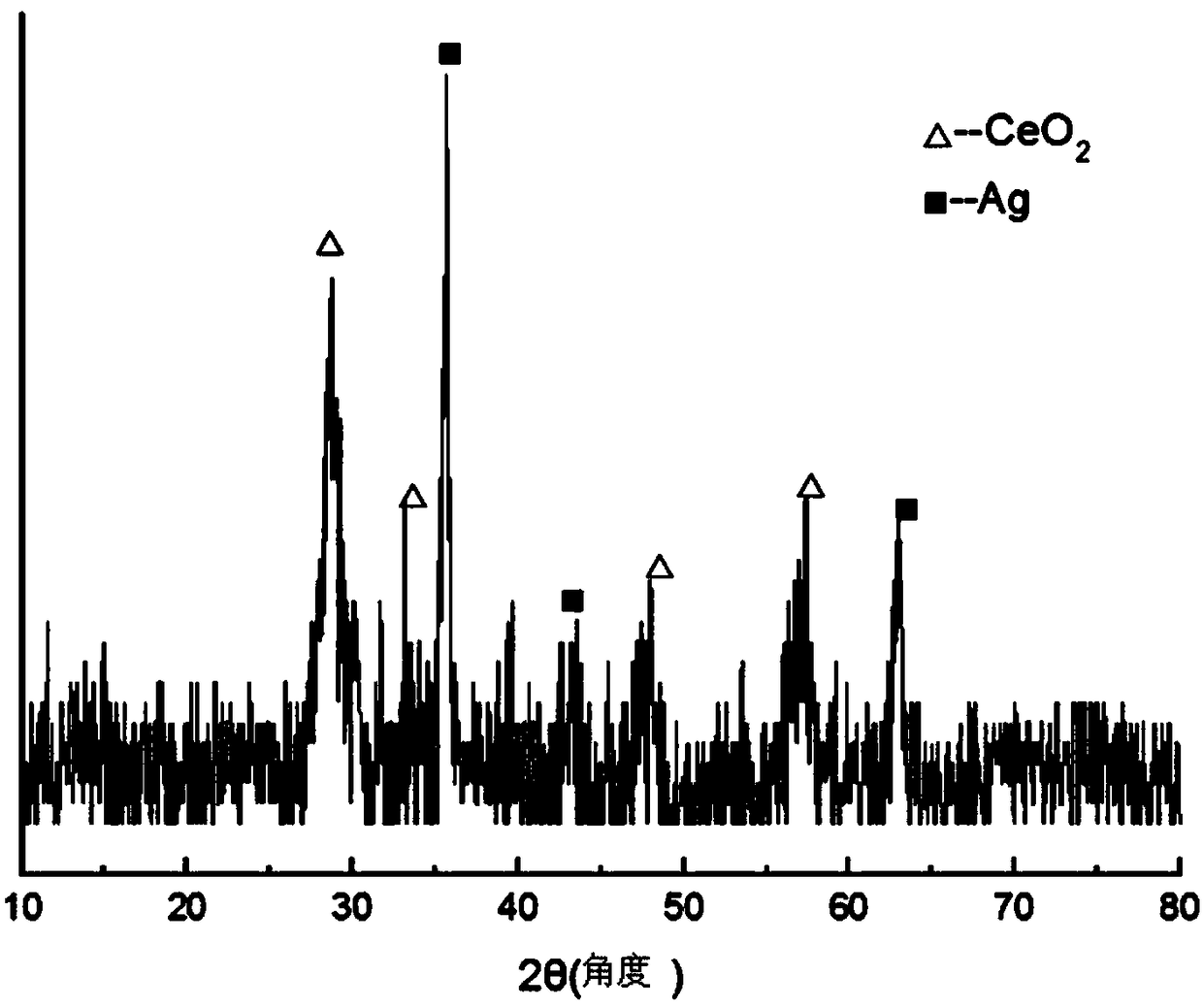

Cerium-based core-shell structure catalyst and preparation method thereof

A core-shell structure and catalyst technology, which is applied in the field of catalysis, can solve problems such as unsatisfactory catalytic effect, poor thermal stability of the catalyst, and complicated steps, and achieve the effects of improving catalytic performance, increasing catalytic activity, and increasing the concentration of oxygen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the first step, mix 40ml of glycerol and 10ml of distilled water to form a solution, add 0.18g of silver nitrate and 0.142g of sodium citrate, ultrasonically disperse, place in a 135°C oil bath, heat and stir at a constant temperature for 1h. Centrifuge, wash, and dry to obtain silver nanoparticles.

[0027] In the second step, 0.2171g of cerium nitrate and 0.1078g of silver nanoparticles were weighed and added to distilled water, 0.26g of citric acid was added, and the pH value was adjusted to 6.7 with 1mol / L of ammonia water to produce dispersion. Magnetic stirring, using the method of pulse laser action to act on the mixed solution for 1.5h, set the laser head perpendicular to the mixed solution (the laser target surface is 5mm away from the liquid surface), so that the laser acts on the mixed solution, and the obtained product is centrifuged and dried. The laser parameters are: power 10 6 w / cm 2 , voltage 720v, pulse width 10ms, frequency 10Hz, wavelength 523nm...

Embodiment 2

[0031] In the first step, mix 40ml of glycerol and 10ml of distilled water to form a solution, add 0.18g of silver nitrate and 0.142g of sodium citrate, ultrasonically disperse, place in a 135°C oil bath, heat and stir at a constant temperature for 1h. Centrifuge, wash, and dry to obtain silver nanoparticles.

[0032] In the second step, 0.4342g of cerium nitrate and 0.1078g of silver were weighed and added to distilled water, 0.26g of citric acid was added, and the pH value was adjusted to 6.7 with ammonia water to produce dispersion. Magnetic stirring was used to act on the mixed solution for 1.5 hours by means of pulsed laser action, and the obtained product was centrifuged and dried. The laser parameters are: power 10 6 w / cm 2 , voltage 720v, pulse width 10ms, frequency 10Hz, wavelength 523nm, energy 250mJ / cm 2 .

[0033] The third step is to use high-temperature sintering method to decompose nitrate to obtain catalyst product, sinter the above-mentioned completely dri...

Embodiment 3

[0036] In the first step, mix 40ml of glycerol and 10ml of distilled water to form a solution, add 0.18g of silver nitrate and 0.142g of sodium citrate, ultrasonically disperse, place in a 135°C oil bath, heat and stir at a constant temperature for 1h. Centrifuge, wash, and dry to obtain silver nanoparticles.

[0037] In the second step, 0.2171g of cerium nitrate and 0.1078g of silver were weighed and added to distilled water, 0.26g of citric acid was added, and the pH value was adjusted to 6.7 with ammonia water to produce dispersion. Magnetic stirring was used to act on the mixed solution for 1.5 hours by means of pulsed laser action, and the obtained product was centrifuged and dried. The laser parameters are: power 10 6 w / cm 2 , voltage 720v, pulse width 10ms, frequency 10Hz, wavelength 523nm, energy 350mJ / cm 2 .

[0038] The third step is to use high-temperature sintering method to decompose nitrate to obtain catalyst product, sinter the above-mentioned completely dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com