Automatic shoelace machine and shoe upper processing method

A processing method and technology for wearing shoelaces, applied in the direction of shoe-making machinery, footwear, clothing, etc., can solve the problems of no significant advantage in the overall operation time, inability to achieve product consistency, and inability to completely save manpower, etc. The effect of reducing operation complexity, reducing time and saving personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0046] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

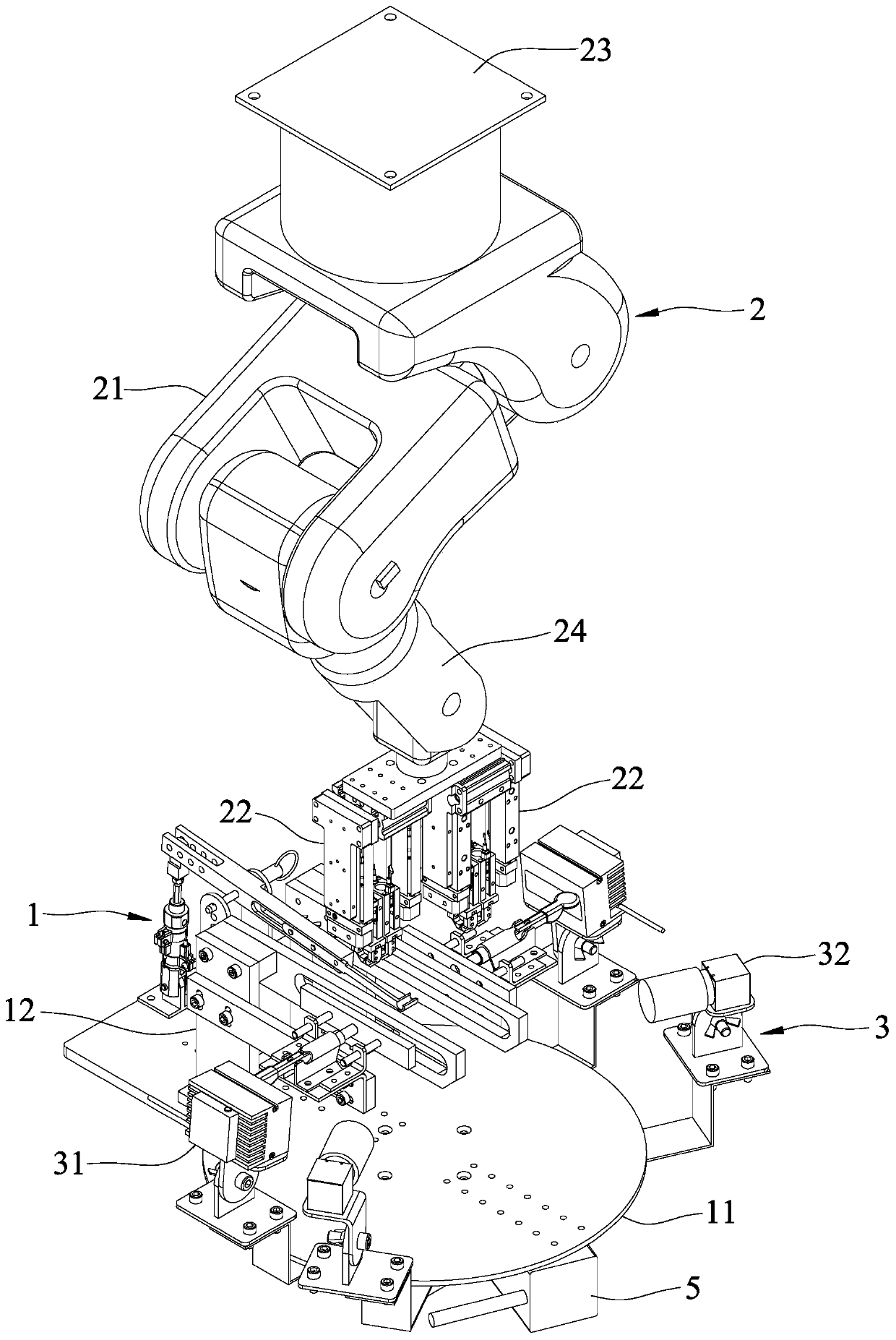

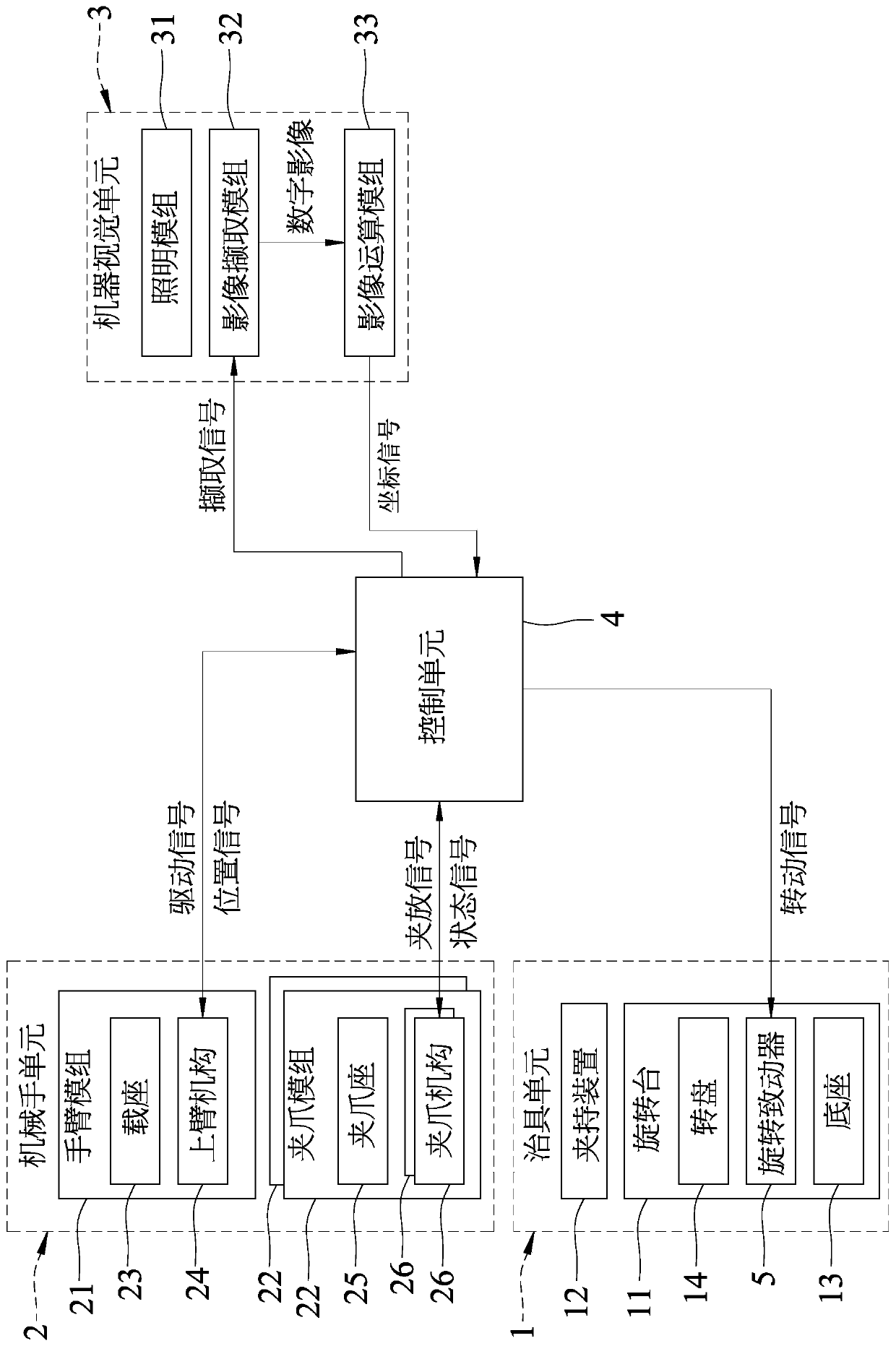

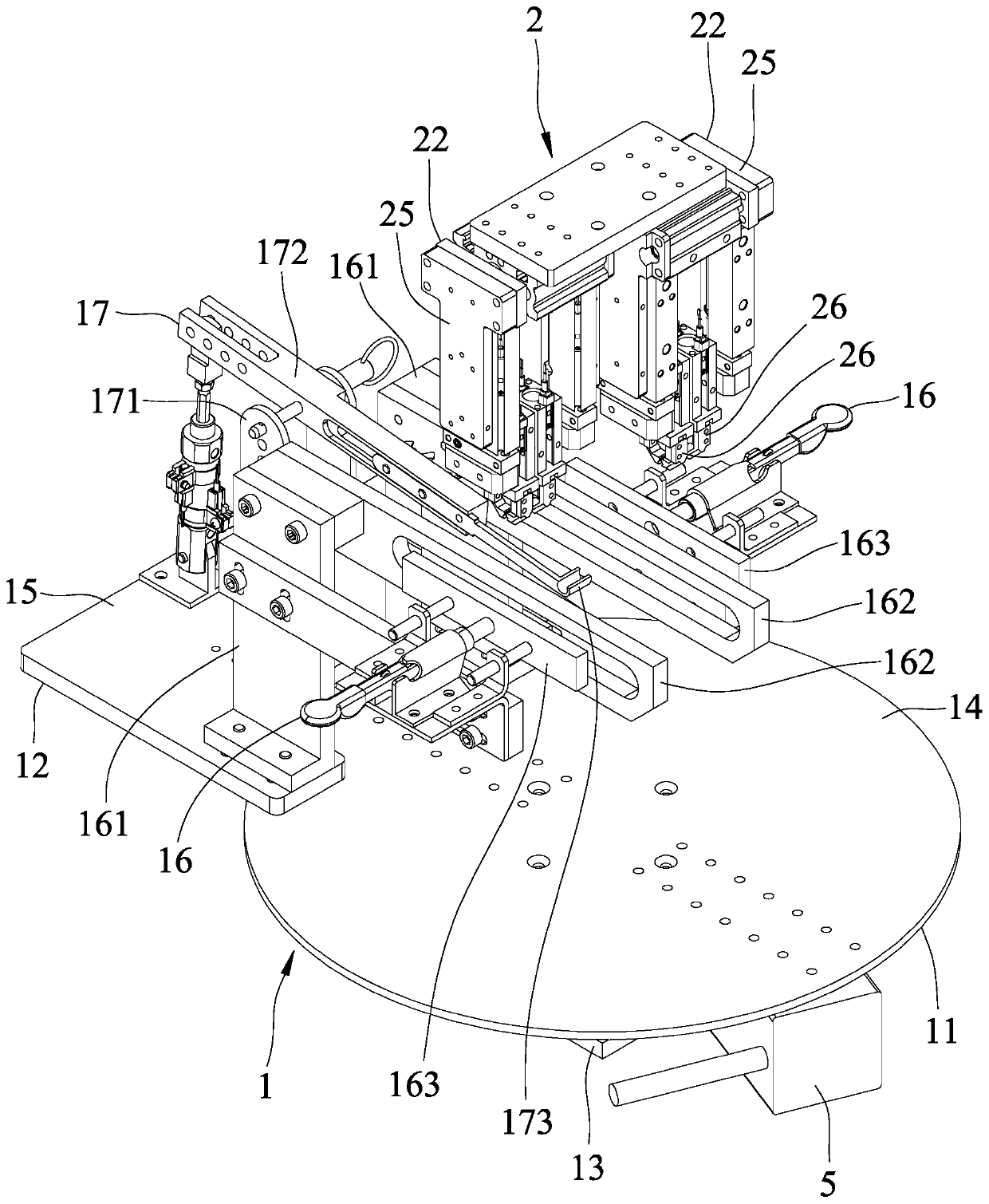

[0047] refer to figure 1 , 2 , 4, is a first embodiment of the automatic shoelace machine of the present invention, the automatic shoelace machine includes a jig unit 1, a manipulator unit 2, a machine vision unit 3 and a control unit 4, and can A shoelace 8 is worn on a vamp portion 9 .

[0048] refer to Figure 4 and Figure 5 , the shoelace 8 includes two end caps 81 and a flexible section 82 connected between the end caps 81 . The vamp portion 9 includes two shoe eyelets 91 arranged at intervals, and a shoe tongue 92 located between the shoe eyelets 91 . Each shoe eyelet 91 has a plurality of shoelace holes 93 arranged through and arranged at intervals. The tongue 92 has a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com