Switch capacitor contactor resistance wire detection fixture

A technology for detecting fixtures and contactors, which is applied in the parts, instruments, measuring electricity and other directions of electrical measuring instruments, can solve the problems of decreased company trust, low work efficiency and accuracy, and high risk of products leaving the factory. The effect of automatic detection function and prevention of product function error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

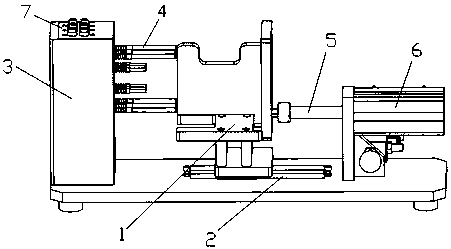

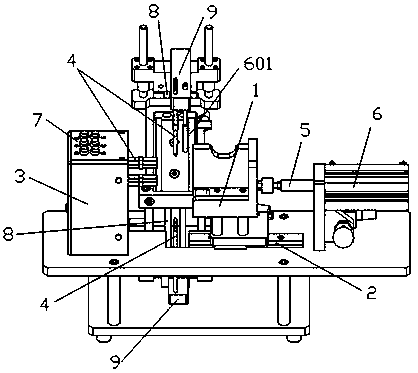

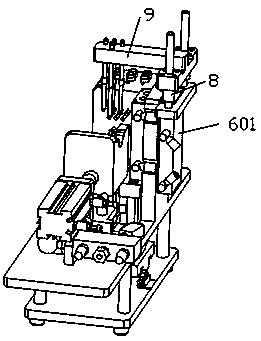

[0019] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0020] A resistance line detection fixture for a switched capacitor contactor, including a transmission mechanism and a detection system, the transmission mechanism includes a cylinder 6, a support plate 1 and a guide rail 2, the detection system includes a chassis 3 and a detection contact 4, and the contactor shell to be tested is placed On the support plate 1, the support plate 1 is arranged on the guide rail 2 and connected with the cylinder 6 through the transmission rod 5. The support plate 1 is driven by the cylinder 6 and slides back and forth on the guide rail 2. The support plate 1 has a test position. After the board 1 moves to the test position, the detection contact 4 is in contact with the contactor to be tested.

[0021] The chassis of the detection system includes: a voltage transformation module, a rectification module, a voltage stabilizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com