A fatigue wear test fixture and test method that can accurately control the radial deformation of a flexspline

A technology of radial deformation and test fixture, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of material waste, the inability to measure the radial deformation of the flexible wheel, and the difficulty in obtaining the influence law of the fatigue wear of the flexible wheel, etc. Achieve the effect of improving experimental efficiency and saving experimental materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

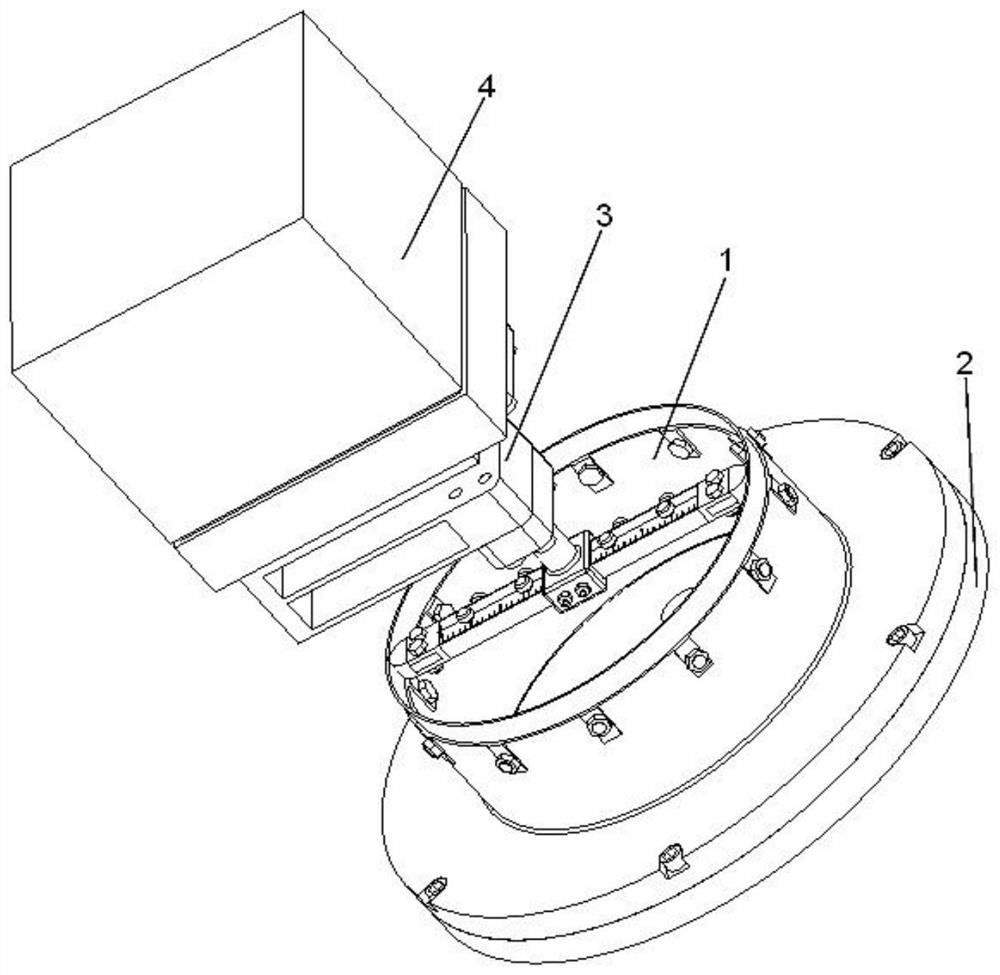

[0063] In the following, the present invention will be described by taking the flexspline of the SHF25-80 harmonic reducer of HD Company as a prototype, but the present invention is not limited thereto.

[0064] The steps to use the fixture in the test are as follows

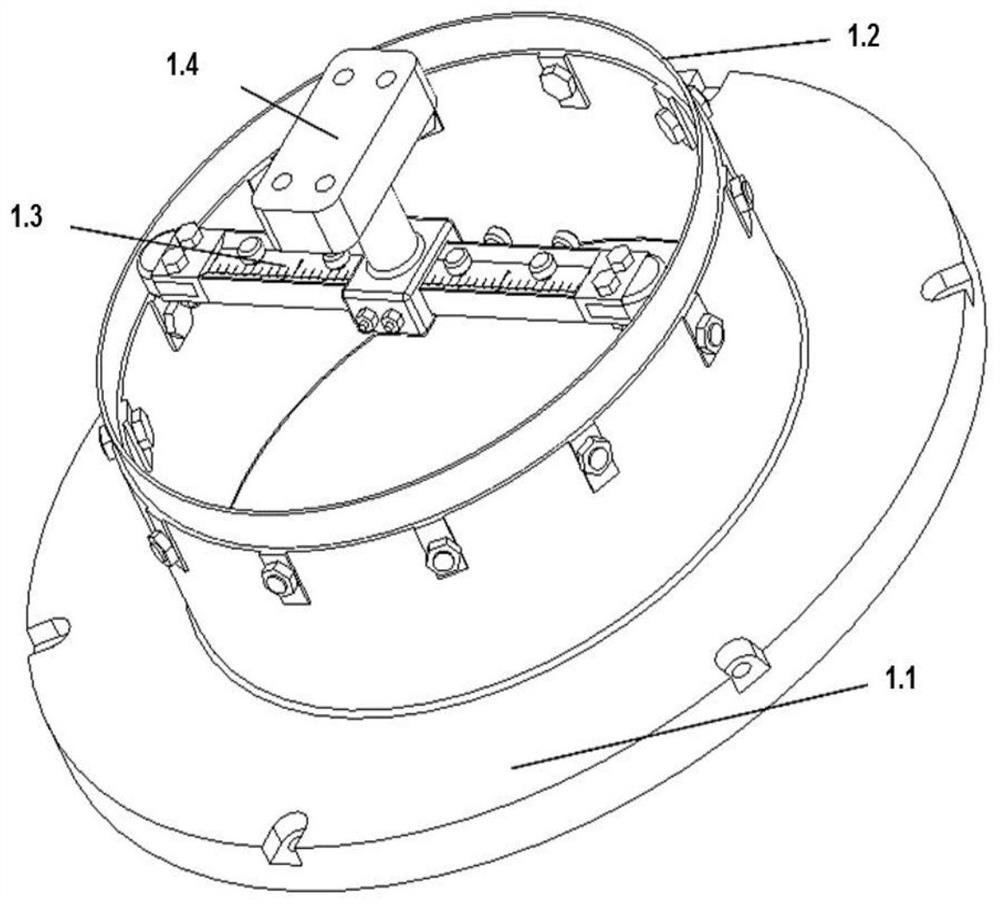

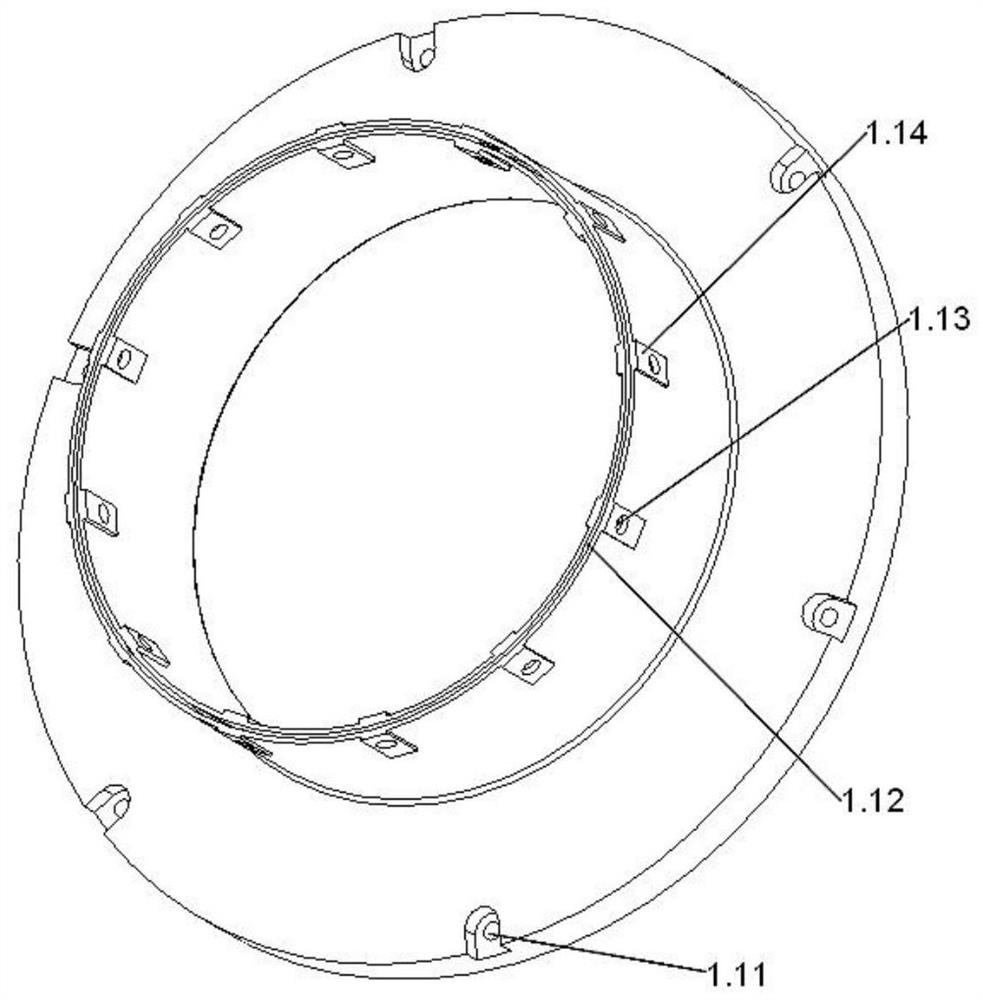

[0065] Step 1: First, assemble the fixture according to the detailed assembly process of the fatigue wear test fixture 1 that can precisely control the radial deformation of the flexspline.

[0066] Step 2: Calculate the radial extension distance L of the vernier caliper according to the formula L=(D+2ΔL-L1) / 2, and slide the main rulers of the vernier caliper on the left and right sides along the dovetail groove guide rail of the vernier caliper for a distance L , and secured by the locking knob.

[0067] Step 3: Apply a layer of grease evenly on the inner wall of the short tube ring, and slowly insert a vernier-like caliper into the short tube ring.

[0068] Step 4: Carry out UMT rotation experiment.

[0069...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com