A kind of interlayer swirling corn drying device

A drying device, corn technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of energy waste, slow water evaporation, waist bursting, etc., to avoid energy loss, broad application prospects, improve uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

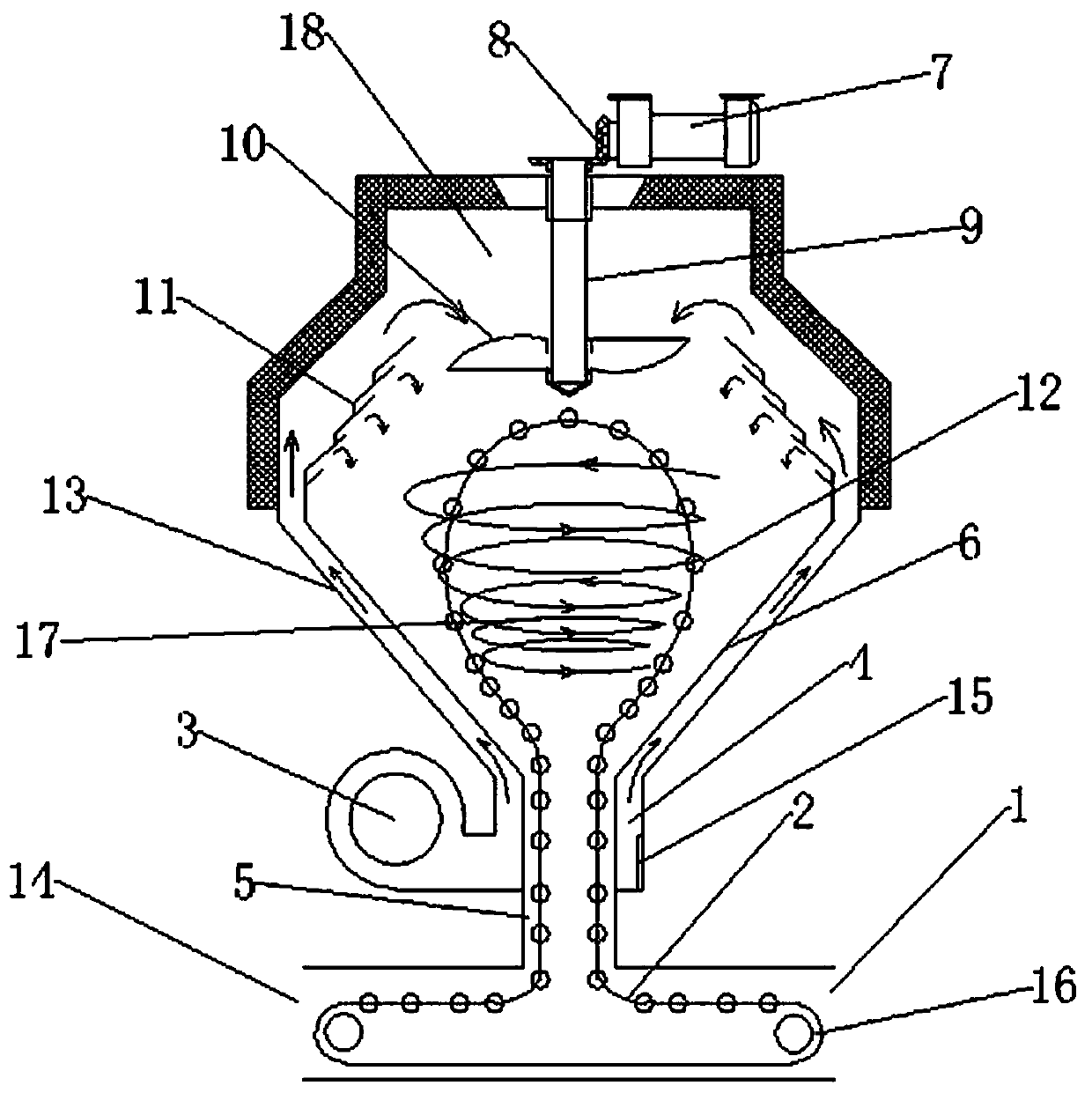

[0019] An interlayer swirling corn drying device, comprising a charging port 1, a conveyor belt 2, a hot air blower 3, a hot air duct 4, a corn transmission channel 5, a drying chamber interlayer 6, an outer wall 13 of the device, a motor 7, a transmission gear 8, a transmission Shaft 9, negative pressure fan 10, drying outlet 14, transmission motor 16, drying chamber 17, and negative pressure chamber 18 are characterized in that annular air inlets 11 are evenly distributed on the surface of the upper half of the interlayer 6 of the drying chamber, and the conveyor belt 2 A rotatable fixing clip 12 is installed on the top, and a spiral guide pipe 15 is provided on the hot air duct 4 . The operation process of a kind of interlayer swirling corn drying device is as follows: first, fix the corn cobs to be dried from the charging port 1 with the rotatable fixing clip 12 on the conveyor belt 2, start the transmission motor 16 to drive the conveyor belt 2 to the drying chamber 17 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com