Air heater for foam plastic production

An air heater and foamed plastic technology, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of unsatisfactory effect, difficult air temperature, and complicated operation, and achieves low production cost and high efficiency. The effect of high-quality production and efficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

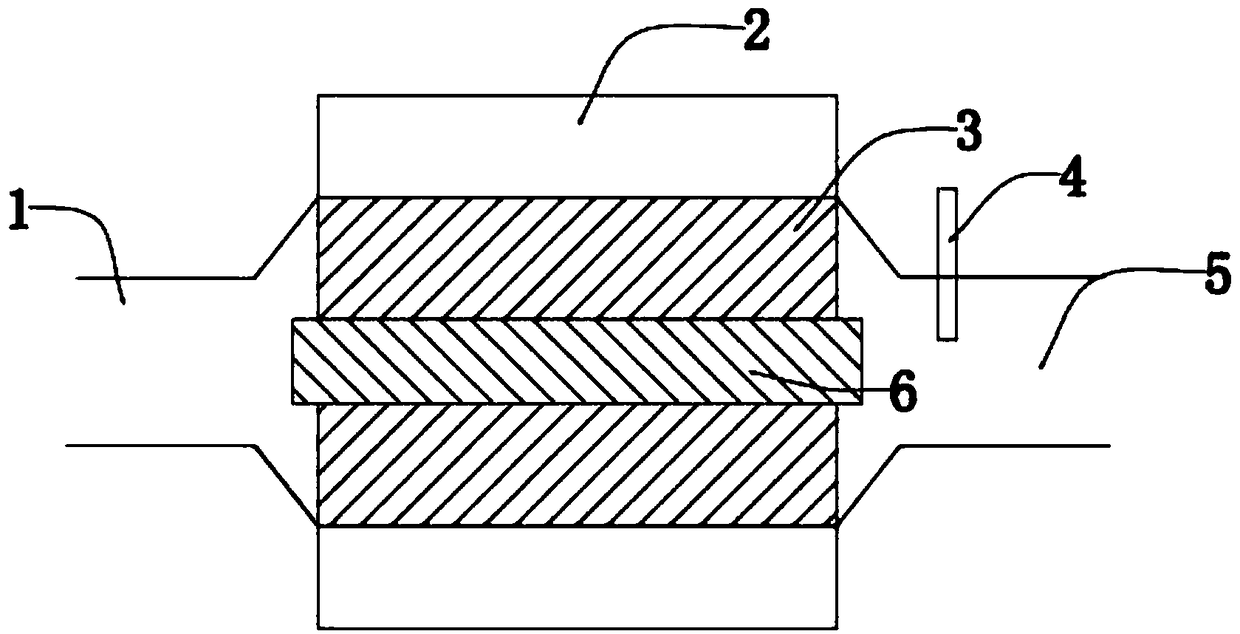

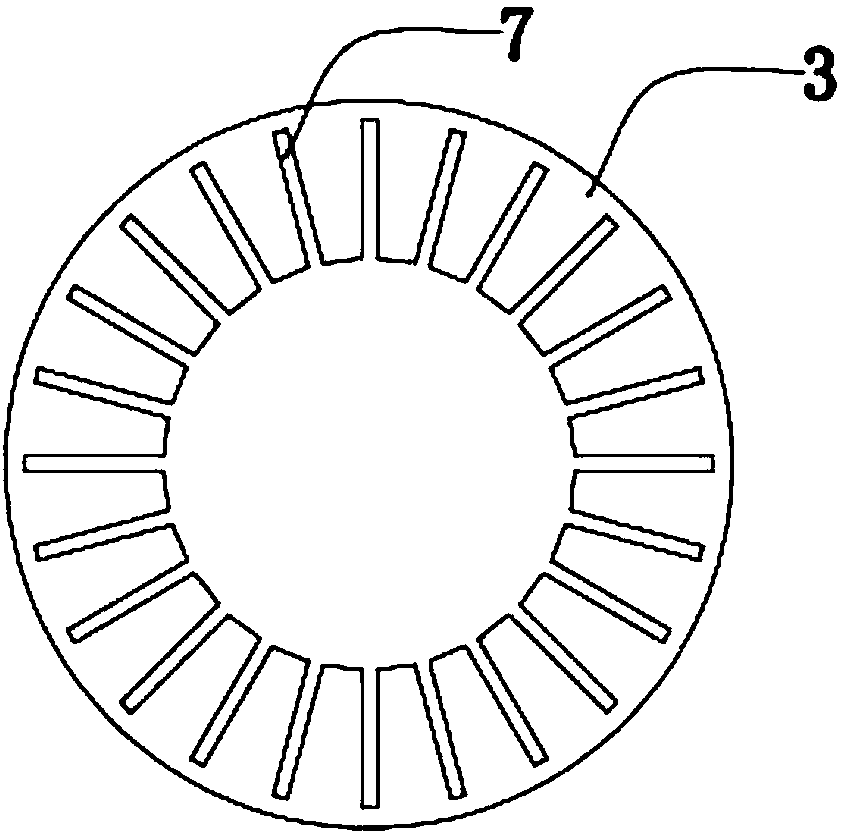

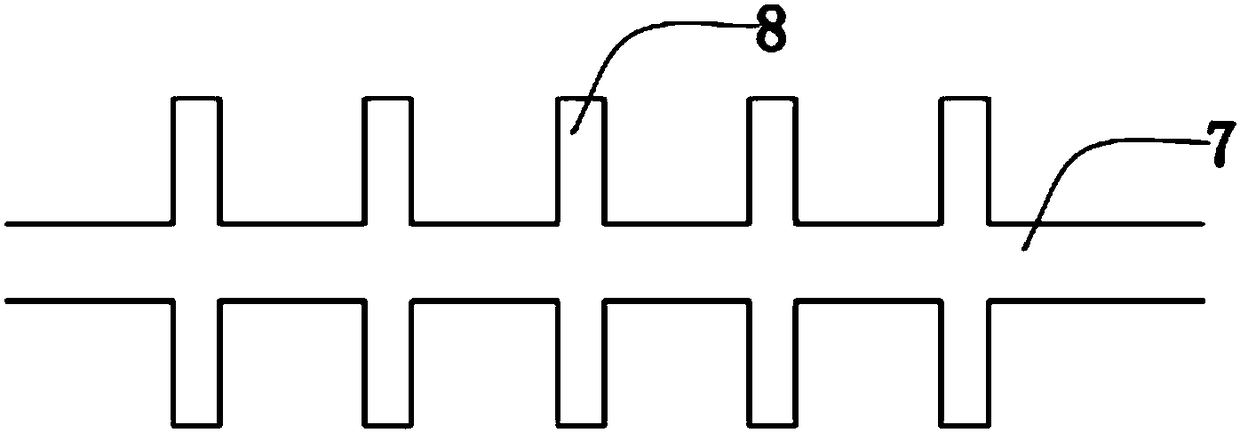

[0019] Such as Figure 1-3 As shown, the present invention includes a hollow pipe body 3, the two ends of the pipe body 3 are respectively connected with an air inlet 1 and an air outlet 5, the pipe body 3 is made of pure copper, and the inner wall of the pipe body 3 is provided with a number of axial The heat exchange tank 7, the pipe body 3 is also provided with a retaining column 6 to fill the hollow area of the pipe body 3, the outer wall of the pipe body 3 is provided with a heating device 2, and the air outlet 5 is provided with a temperature detection device 4; The grooves 7 are evenly distributed on the inner wall of the pipe body 3 , and the heat exchange grooves 7 are provided with a plurality of tooth grooves 8 along the axial direction of the pipe body 3 .

[0020] Concrete mode of wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com