Single-body bearing pedestal for spandex guide roller

A bearing seat, spandex yarn technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of waste of spandex yarn cakes, fixed and unadjustable spacing, etc., to solve the problem of low utilization rate and simple structure , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

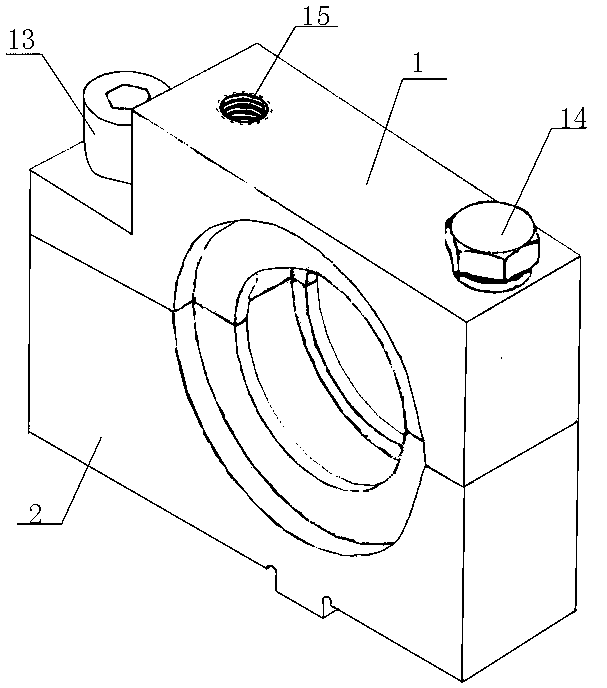

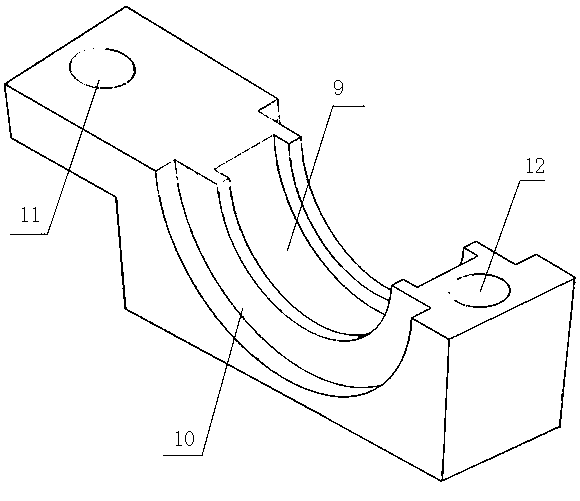

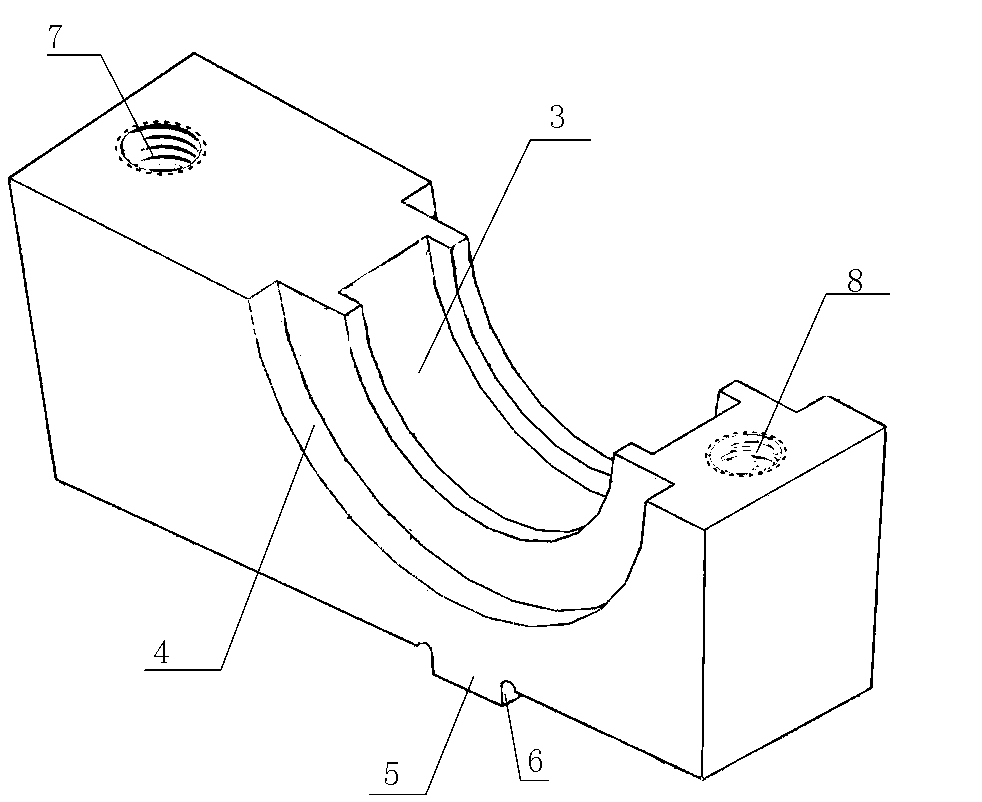

[0015] refer to Figure 1 ~ Figure 3 To further elaborate the present invention, a single bearing housing for spandex yarn guide rollers includes an upper assembly block 1 and a lower assembly block 2 connected in combination, the lower assembly block 2 is rectangular, and the upper part of the lower assembly block 2 is provided with a semicircle The lower bushing 3 of the lower bushing 3 is symmetrically arranged on both sides of the lower bushing 3 with a lower side boring groove 4 of a semi-circular arc structure, and the top end surface of the lower combination block 2 is located on both sides of the lower bushing 3. Bolt holes A7 and bolt holes are respectively provided B8, the end surface of the bottom of the lower combination block 2 is provided with a bump 5, and the two ends of the bump 5 are symmetrically provided with the same keyway 6 as the axial direction of the lower bushing 3; the upper combination block 1 is stepped, and the lower part of the upper combination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com