A compressor stable oil supply device and a scroll compressor

An oil supply device and compressor technology, which is applied in the field of compressors, can solve the problems of being unable to absorb non-ferrous impurities, and achieve the effects of reducing the risk of impurities, avoiding excessive shaking, and avoiding excessive amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

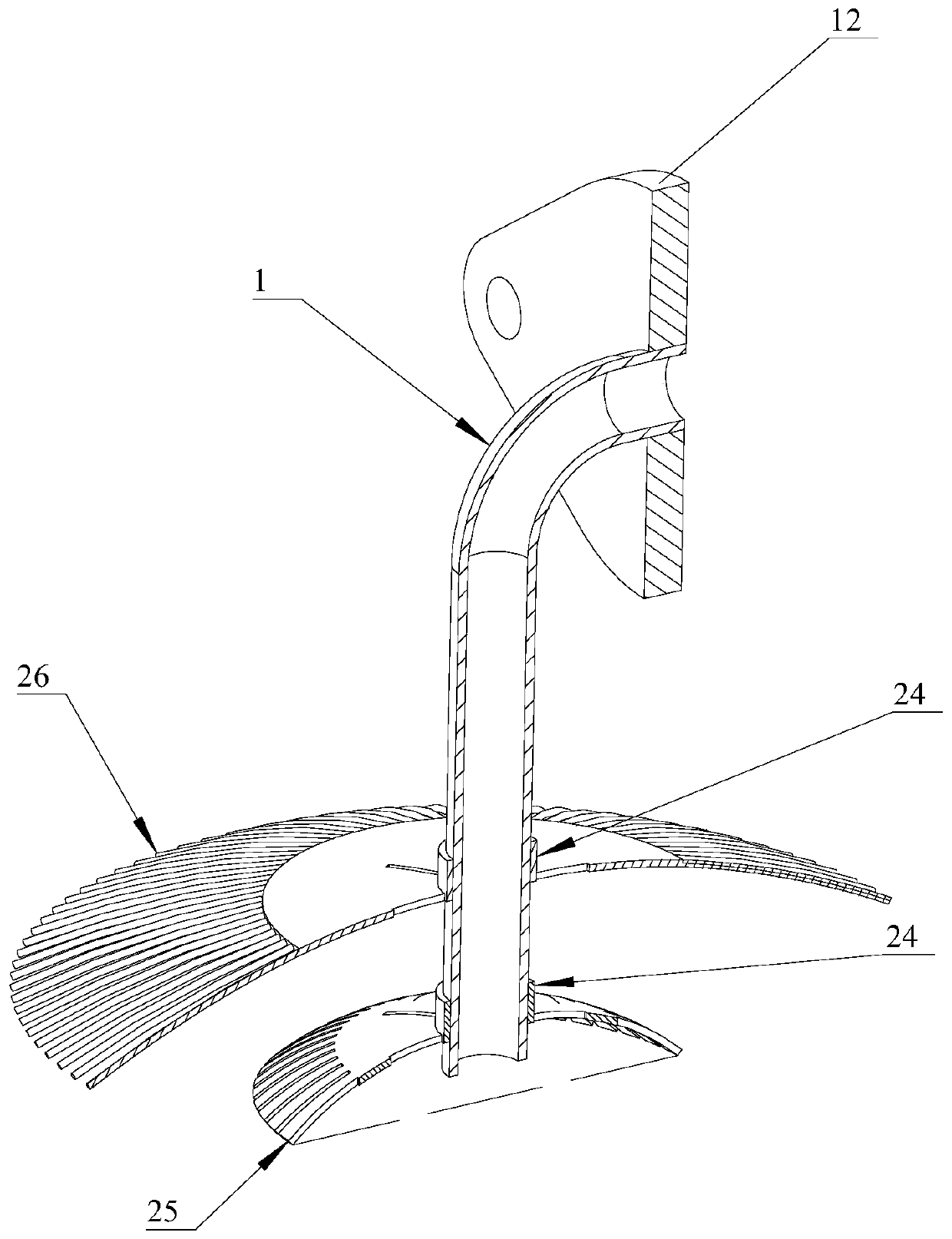

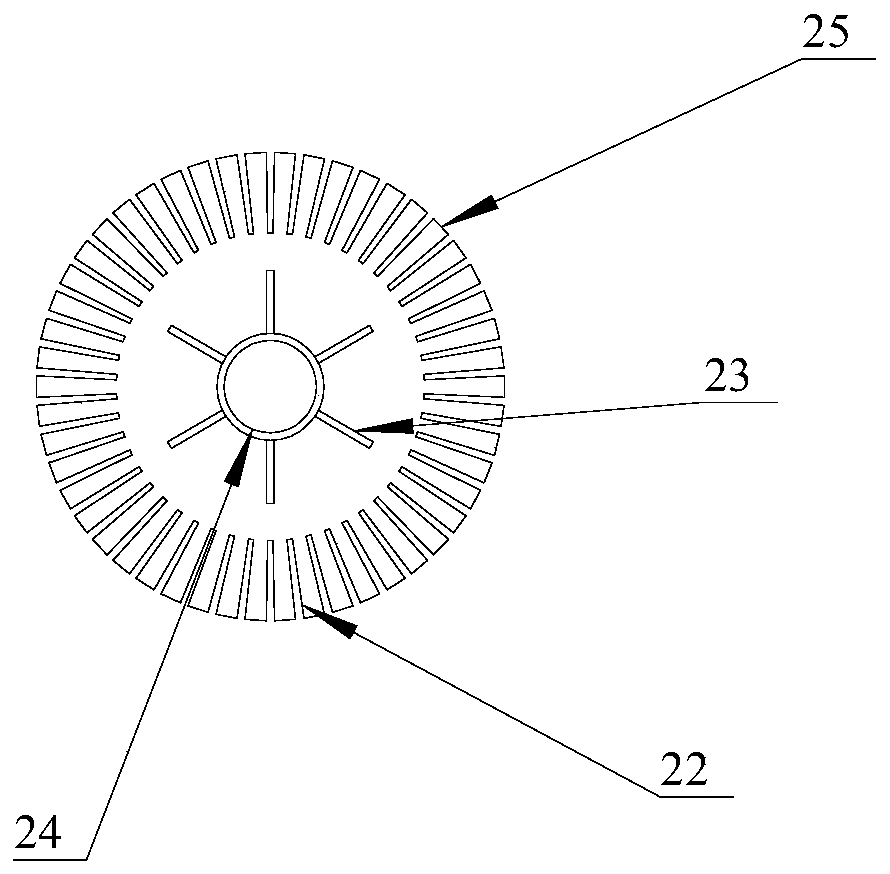

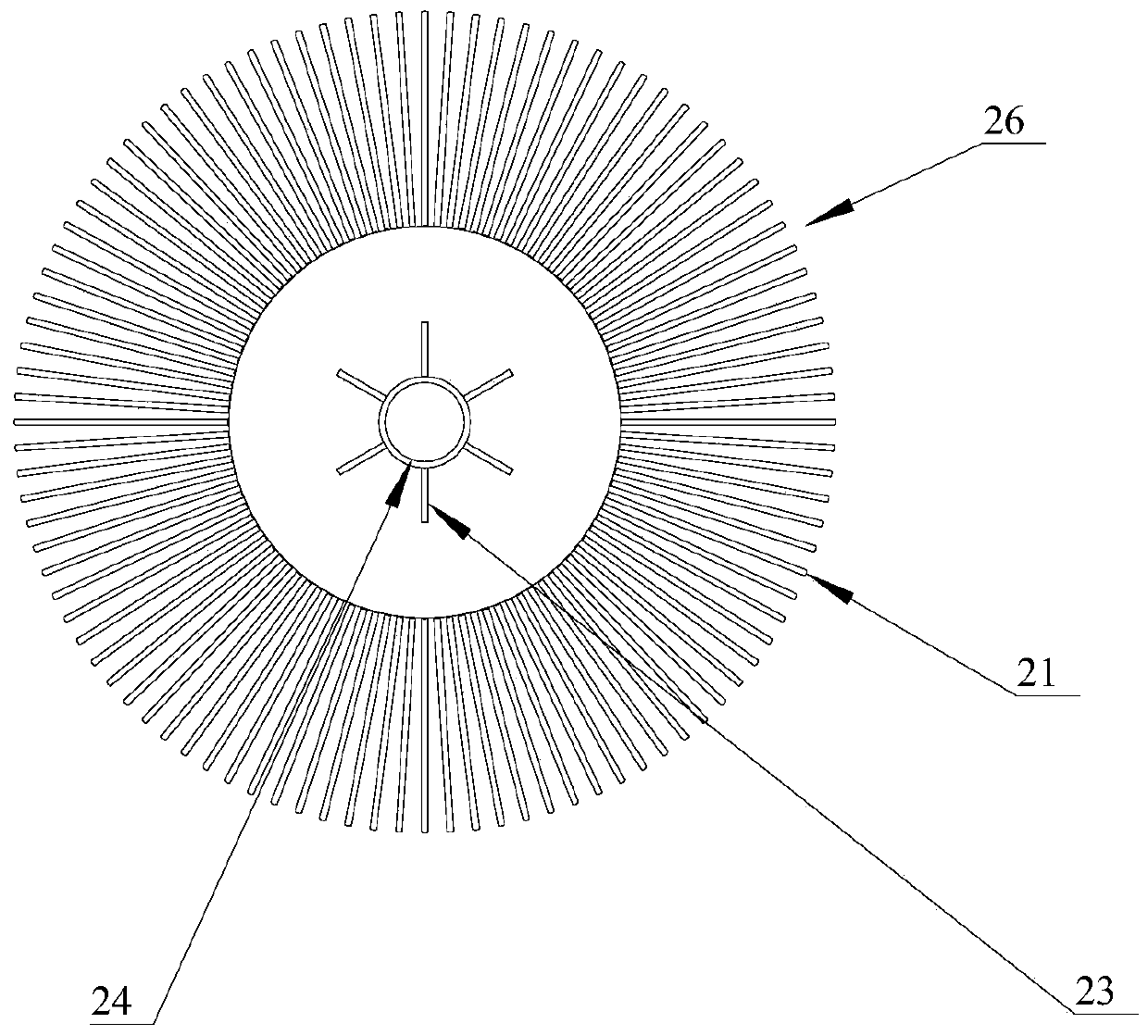

[0023] refer to Figure 1 to Figure 4 , which shows the specific structure of the preferred embodiment of the present invention. The structural features of each component of the present invention will be described in detail below.

[0024] The present invention provides a stable oil supply device for a compressor, including an oil suction pipe 1, the oil suction pipe 1 has an oil suction end that can extend into the lubricating oil, and the oil suction pipe can extend into the lubricating oil vertically or obliquely. 1. At least one damper is provided at the oil suction end, and the damper includes a mounting part connected to the oil suction pipe and an oil stabilization flange extending to the periphery, and the periphery of the oil stabilization flange is provided with a bubble breaking structure. In the present invention, one or more dampers are arranged on the oil suction pipe 1, which can avoid excessive air bubbles in the lubricating oil, especially large air bubbles, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com