Low-modulus room temperature vulcanization neutral silicone weather-proof sealant and preparation method and application thereof

A room temperature vulcanization, low modulus technology, used in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of reducing modulus, increasing elongation, slow surface drying speed, etc., to promote high displacement gap filling , the effect of high elastic recovery rate and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0040] Preparation of low modulus RTV neutral silicone weathering sealants:

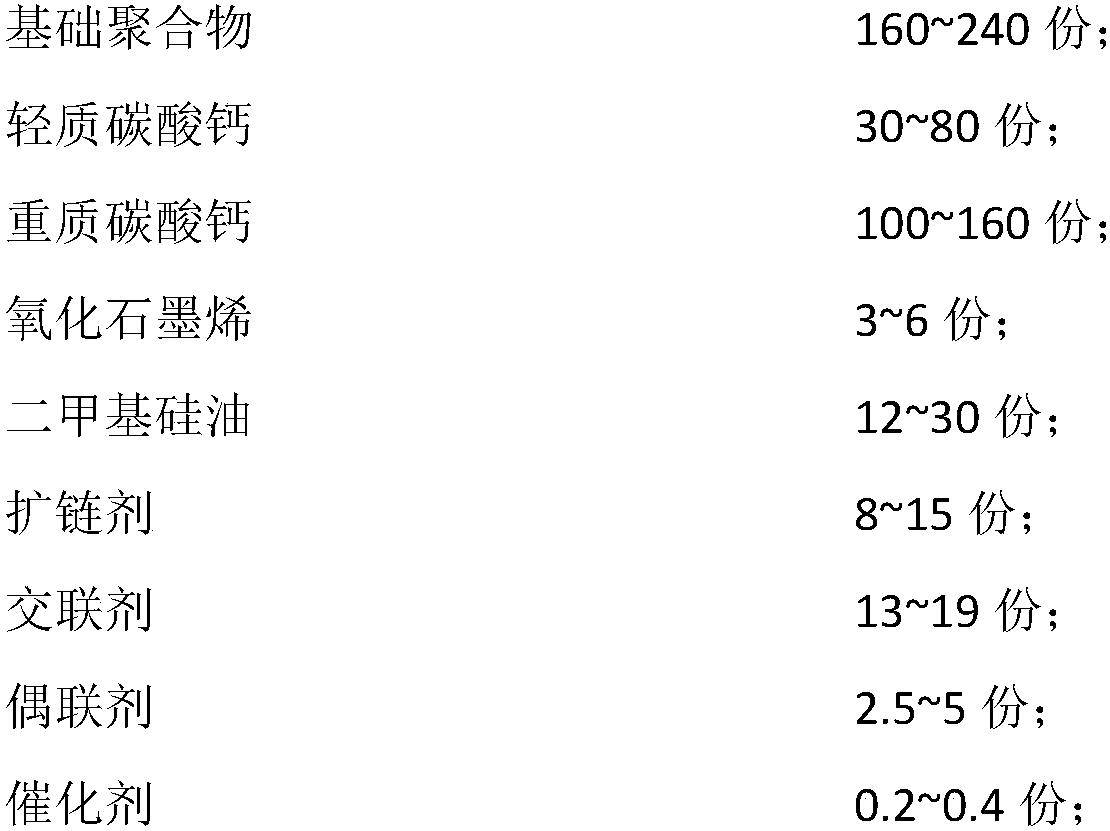

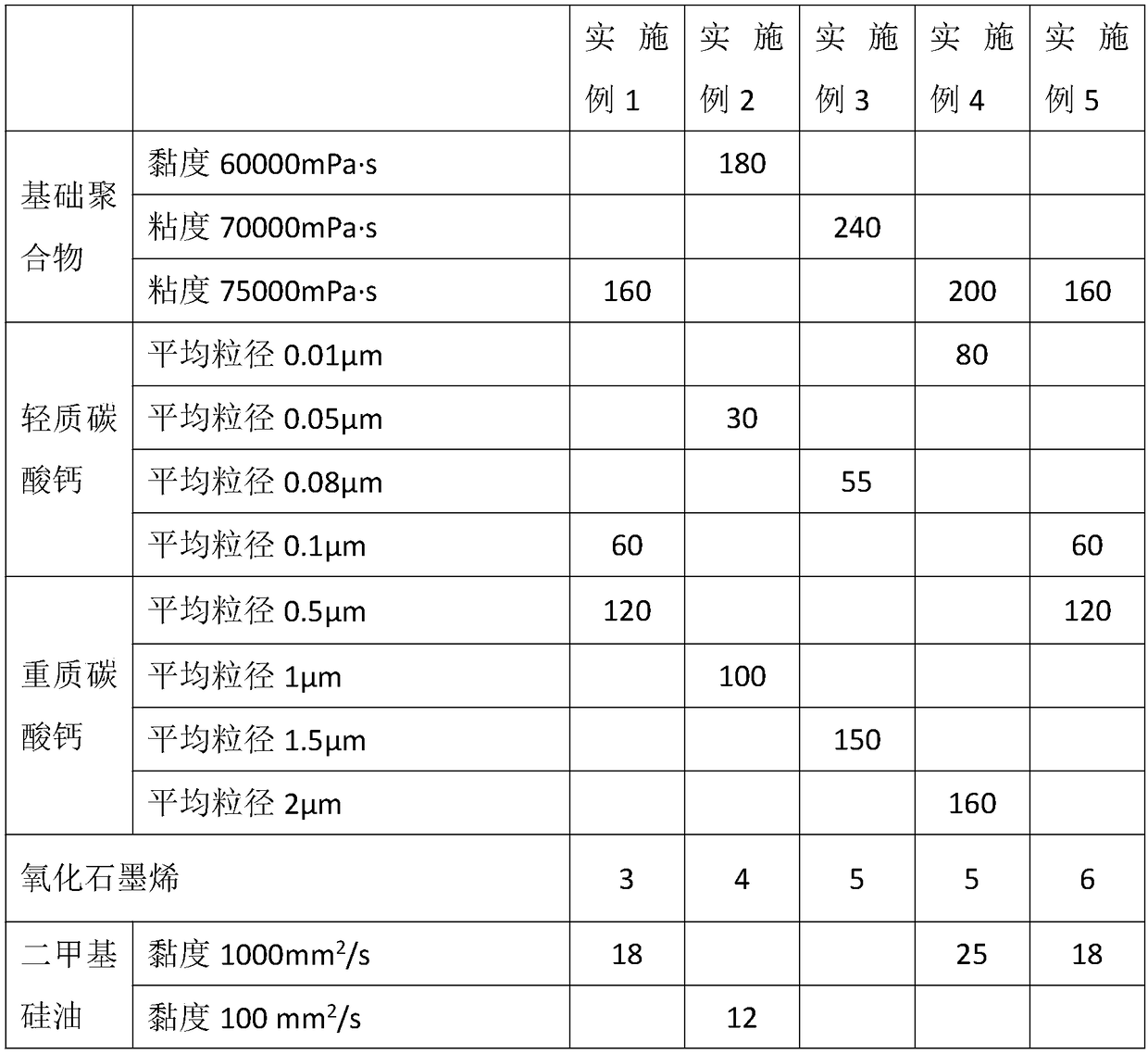

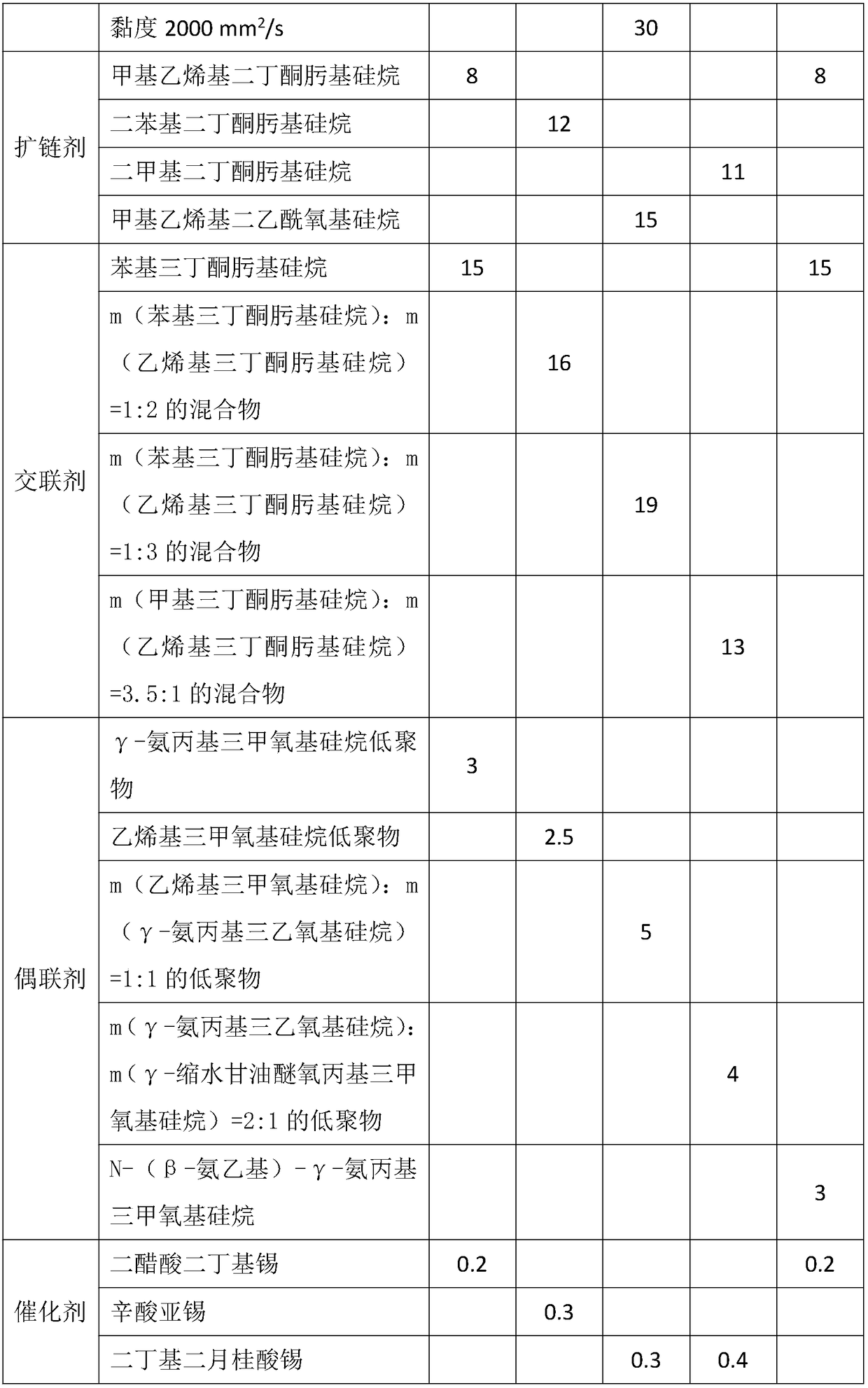

[0041] The raw material consumption of embodiment 1~5 is as shown in table 1;

[0042] Reaction conditions are as shown in table 2 in the preparation step of embodiment 1~5;

[0043] Preparation steps:

[0044] S1. Mix and stir the base polymer, simethicone and chain extender at T1(°C) for t1(min), then add light calcium carbonate, heavy calcium carbonate and graphene oxide at T2(°C), Under the vacuum degree of P1 (MPa), stir and dehydrate for t2 (min), and obtain the base material after cooling;

[0045]S2. At room temperature, add the base material of S1. into a planetary stirring tank, then add a crosslinking agent, a coupling agent and a catalyst, and react t3 (min) at a vacuum degree of P2 (MPa) and a rotational speed of r (rpm). , the one-component room temperature vulcanization low modulus neutral silicone weather-resistant sealant is obtained.

[0046] Table 1 The amount of raw materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com