Composite active black dye and application thereof

A reactive black and dye technology, applied in the field of textile printing and dyeing, can solve the problems of unfavorable energy saving and environmental protection, poor color reproducibility, incomplete coloring, etc., to reduce the cost of sewage treatment and raw material costs, shorten the time-consuming dyeing process, and improve coloring The effect of synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

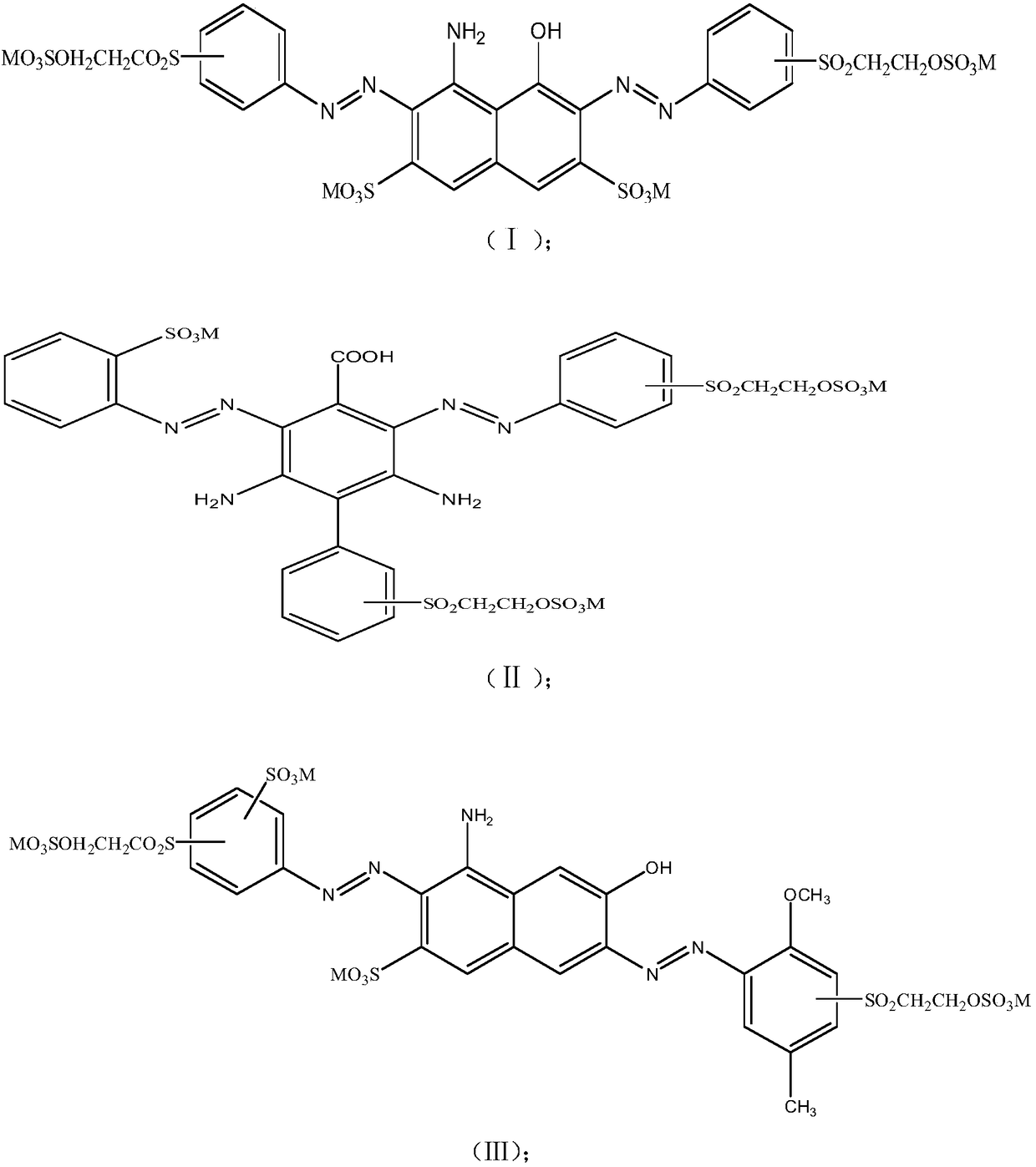

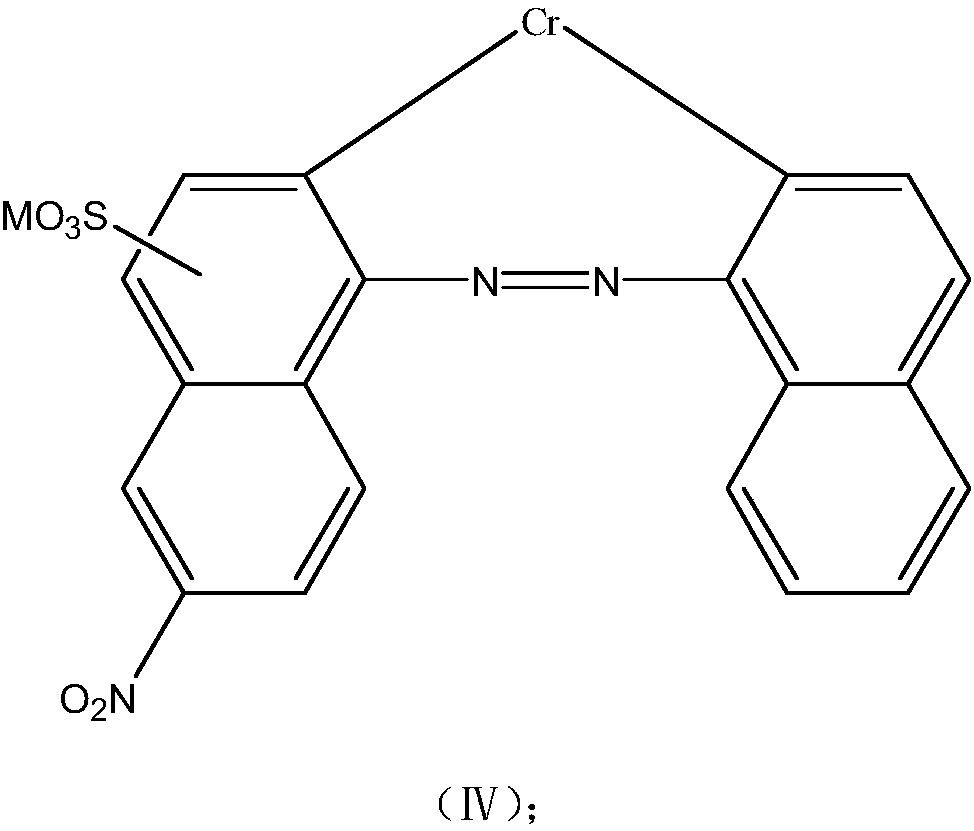

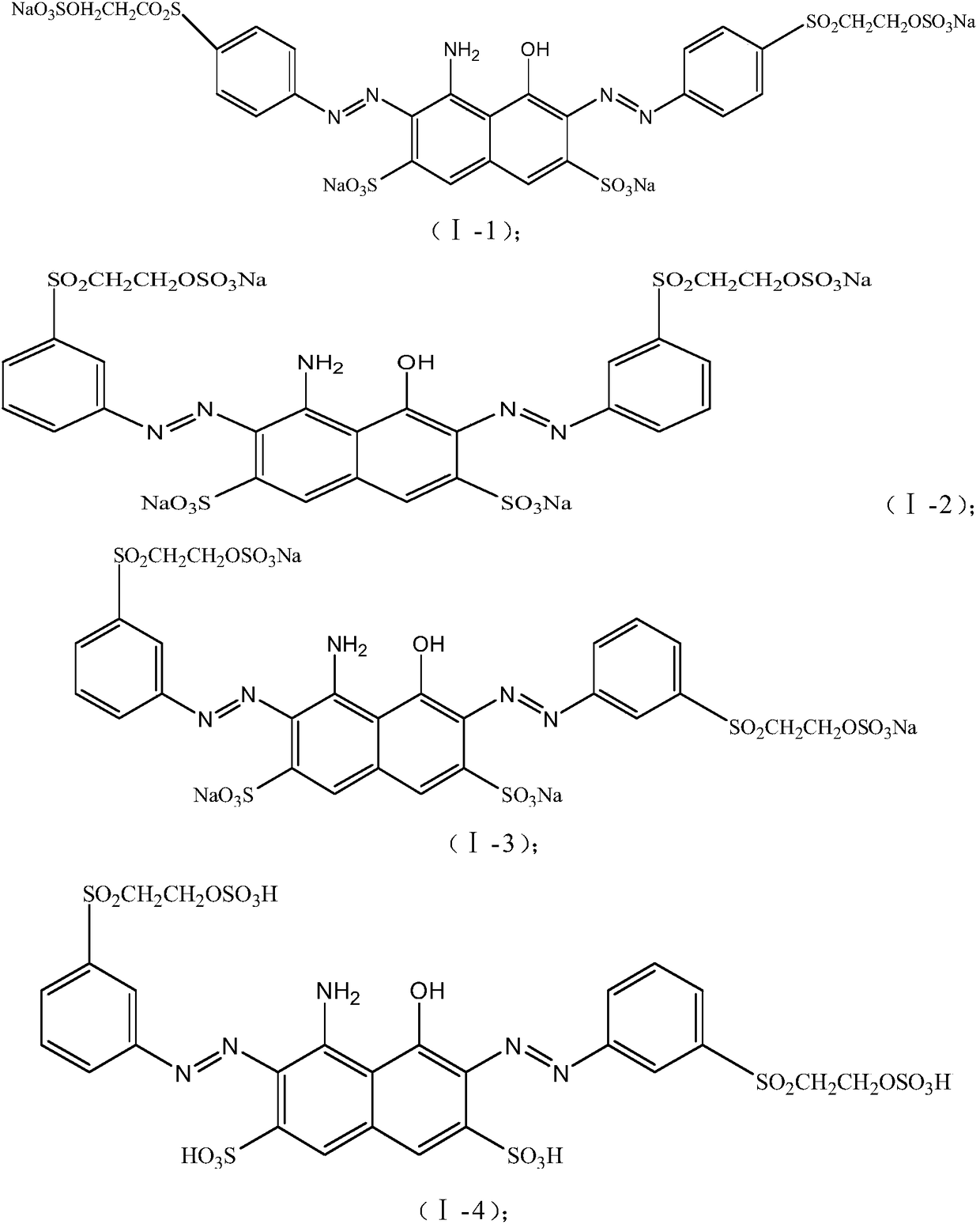

[0049] The present embodiment provides a composite reactive black dye, which comprises the following components in terms of mass percentage: 45% of component A shown in formula (I-1), component B shown in formula (II-1) 20%, 5% of component C shown in formula (III-1), 10% of component D shown in formula (IV-1), and 20% of sodium sulfate.

[0050] Preparation method: weigh each component according to the formula ratio, then mix and stir evenly to obtain the composite reactive black dye.

Embodiment 2

[0052] The present embodiment provides a composite reactive black dye, which comprises the following components in terms of mass percentage: 48% of component A shown in formula (I-2), component B shown in formula (II-3) 19%, 4% of component C shown in formula (III-1), 9% of component D shown in formula (IV-2), and 20% of sodium sulfate.

[0053] The preparation method is the same as in Example 1.

Embodiment 3

[0055]The present embodiment provides a composite reactive black dye, which comprises the following components in terms of mass percentage: 50% of component A shown in formula (I-3), component B shown in formula (II-2) 18%, 6% of component C shown in formula (III-2), 8% of component D shown in formula (IV-1), and 18% of sodium sulfate.

[0056] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com