Method for preparing two-dimensional sheet-shaped Cu-MOF (Metal Organic Framework) material

A flake, cu-btc technology, applied in carboxylate preparation, organic chemistry methods, chemical instruments and methods, etc., can solve the problems of low yield, limit the promotion and application of two-dimensional MOF materials, harsh conditions, etc., and achieve catalytic The effect of high activity, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mix Cu-BTC and urea solution with pH=9 at a solid-to-liquid ratio of 1 / 100g / ml, stir at 25°C for 5 hours, filter, wash, and dry to obtain a two-dimensional sheet-like Cu-MOF-25 with a thickness of 30nm ~ 100nm. In the catalytic oxidation experiment of styrene, the conversion rate reached 98.97% when reacting for 5 hours.

Embodiment 2

[0029] Mix Cu-BTC and sodium hydroxide solution with pH=10 at a solid-to-liquid ratio of 1 / 80g / ml, stir at 80°C for 2 hours, filter, wash, and dry to obtain two-dimensional flaky Cu-MOF-80, which The thickness is 200nm-300nm. In the catalytic oxidation experiment of styrene, the conversion rate reached 97.42% when reacting for 5 hours.

Embodiment 3

[0031] Mix Cu-BTC and ammonia aqueous solution with pH=12 at a solid-to-liquid ratio of 1 / 50g / ml, stir at 120°C for 1 hour, filter, wash, and dry to obtain two-dimensional sheet-like Cu-MOF-120 with a thickness of 400nm ~ 500nm. In the catalytic oxidation experiment of styrene, the conversion rate reaches 97.15% when reacting for 5 hours.

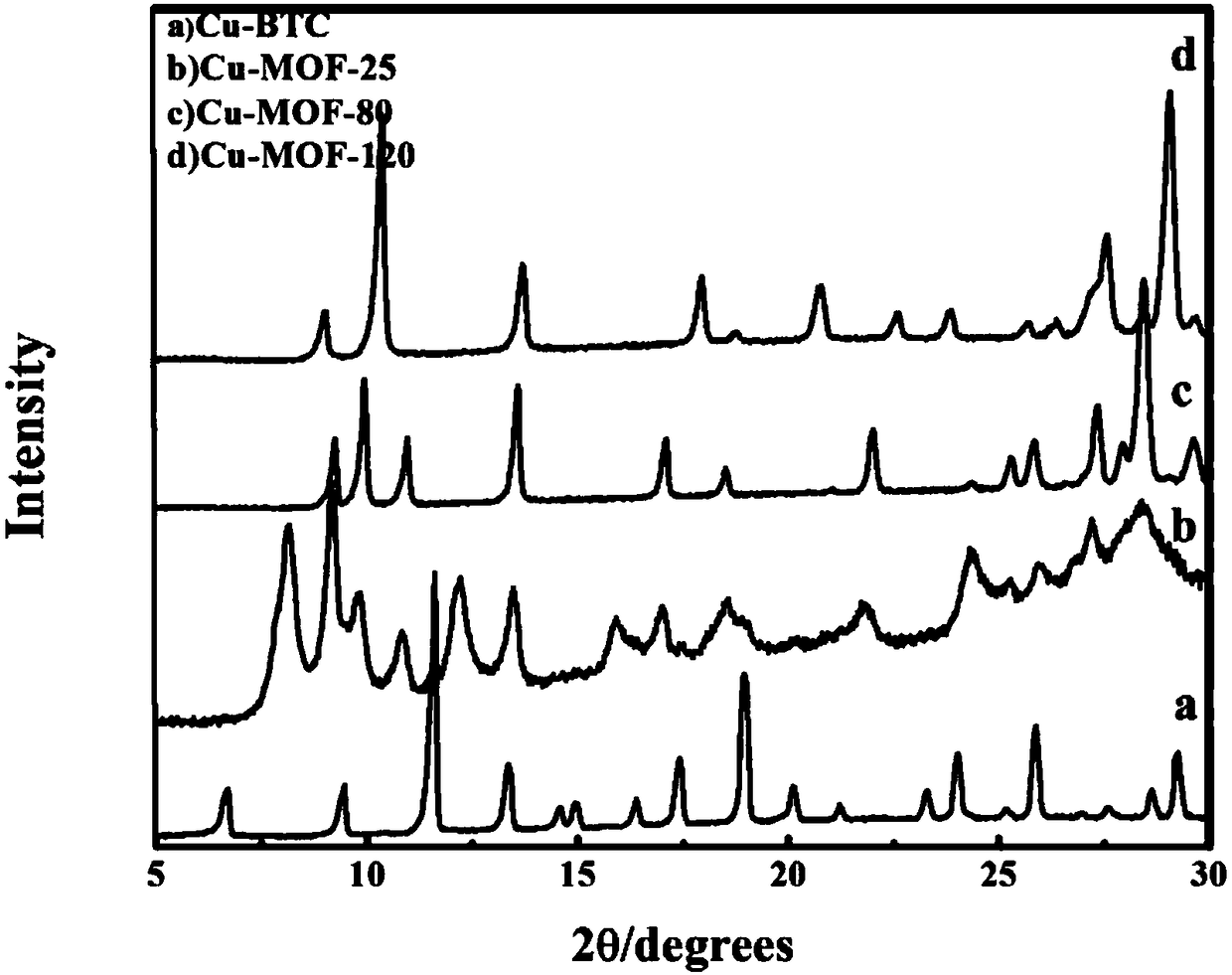

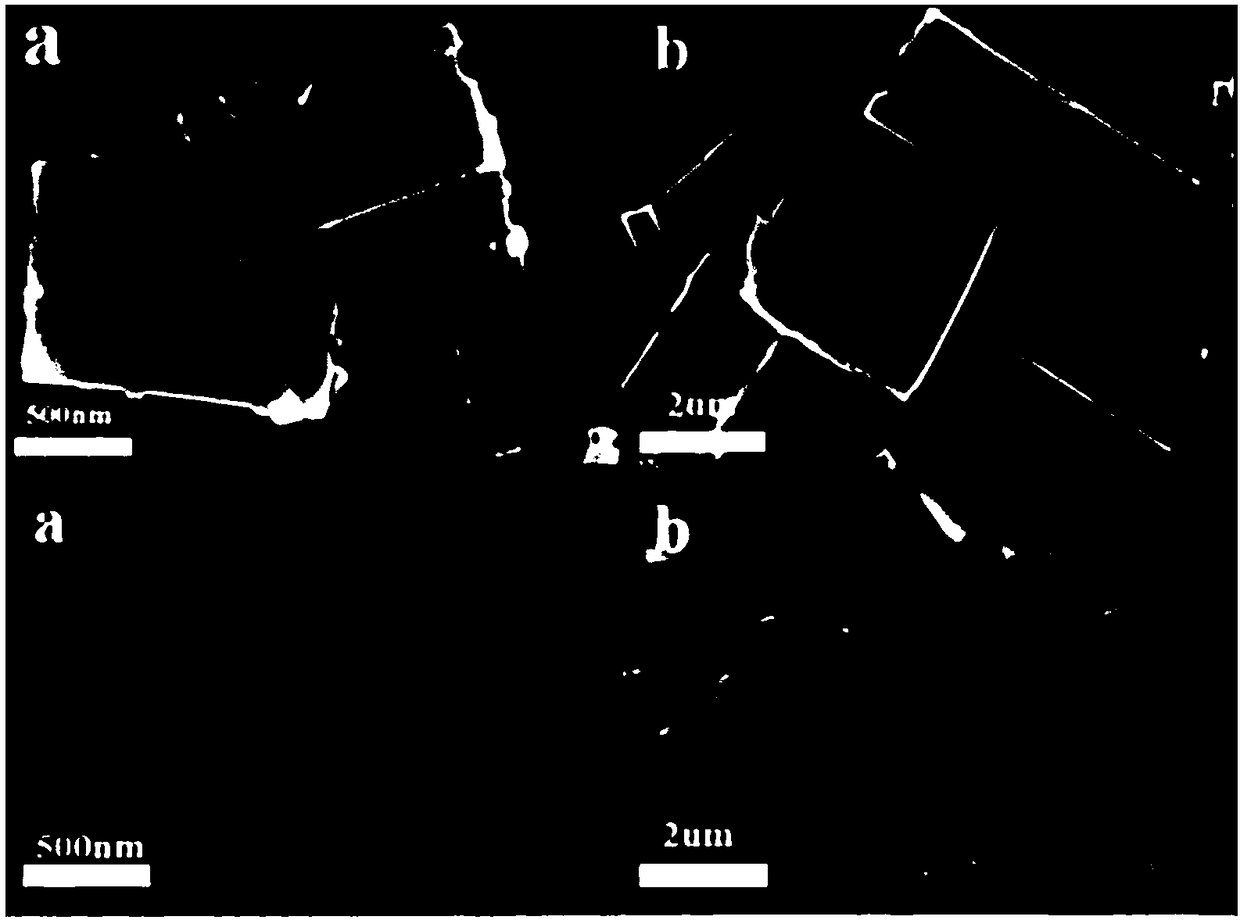

[0032] In the above examples, the XRD comparison diagram of the crystal structure before and after Cu-BTC transformation is as follows figure 1 Wherein a) is Cu-BTC before transformation, b) is the XRD pattern of Cu-MOF after transformation at 25°C in Example 1, and c) is Cu-MOF after transformation at 80°C in Example 2 d) is the XRD pattern of Cu-MOF transformed at 120°C in Example 3. Scanning electron micrographs (SEM) of the transformed crystal morphology as figure 2 Shown, where a is the SEM image of the Cu-MOF transformed at 25°C in Example 1, and b is the SEM image of the Cu-MOF transformed at 80°C in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com