River sediment resource utilization method

A river sediment and resource utilization technology, applied in chemical instruments and methods, sludge treatment, pyrolysis treatment of sludge, etc., can solve the problem of less river sediment, achieve resource utilization, and realize in-situ stabilization and harmless treatment, and the effect of solving the problem of sediment disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

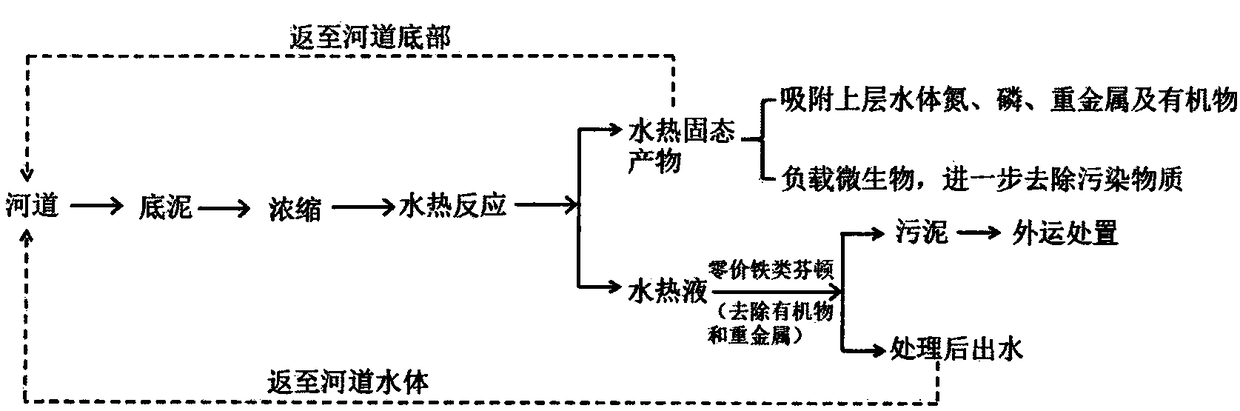

[0023] A method for resource utilization of river bottom mud, comprising the following steps:

[0024] (1) if figure 1 As shown, the river channel sediment produced by dredging and dredging of the river channel is placed in the concentration tank for gravity sedimentation and concentration, and the concentration of the sediment after concentration is 15g / L;

[0025] (2) Pump the concentrated bottom sludge into the hydrothermal closed reaction tank. The injection amount of the concentrated bottom sludge is 50% of the volume of the reaction tank. The steam heating method is used to seal and heat the sludge in the tank to a temperature of 180°C. Keep for 120min;

[0026] (3) The material after cooling is transported to the regulating tank, and treated by centrifugal dehydration to obtain hydrothermal liquid and hydrothermal solid products;

[0027] (4) The hydrothermal liquid adopts zero-valent iron Fenton to remove organic matter and heavy metals. The dosage of zero-valent iro...

Embodiment 2

[0030] A method for resource utilization of river bottom mud, comprising the following steps:

[0031] (1) if figure 1 As shown, the dredging and dredging sediment of the river channel is deposited and concentrated in the concentration tank, and the concentration of the sediment after concentration is 20g / L;

[0032] (2) pump the concentrated bottom sludge into the high-pressure closed reaction tank, the injection amount of the sludge is 70% of the volume of the high-pressure closed reaction tank, heat with heat transfer oil, and heat the sludge in the tank until the temperature of the tank is 180°C. Keep for 160min:

[0033] (3) After the reaction is completed, the material is cooled and unloaded to the regulating tank, and dehydrated by plate and frame filter press to obtain hydrothermal liquid and hydrothermal solid products.

[0034] (4) The hydrothermal liquid adopts zero-valent iron Fenton to remove organic matter and heavy metals. The dosage of zero-valent iron powder...

Embodiment 3

[0037] A method for resource utilization of river bottom mud, comprising the following steps:

[0038] (1) if figure 1 As shown, the spoiled sediment obtained by dredging the river channel is pumped into the concentration tank for sediment concentration, and the concentration of the concentrated sediment is 20g / L;

[0039] (2) pump the concentrated sludge into the hydrothermal closed reaction tank, the injection amount of the sludge is 80% of the volume of the carbonization reaction tank, and steam is heated to the temperature of the sludge in the tank to be 200°C, and kept for 200min;

[0040] (3) After the reaction is completed, the temperature is lowered, and the material is transported to the regulating tank, and dehydrated by plate and frame filter press to obtain hydrothermal liquid and hydrothermal solid products.

[0041] (4) The hydrothermal solution is treated with zero-valent iron Fenton, which is used for the removal of organic matter and heavy metals. The dosage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com