Mobile phone component welding detection device

A welding inspection and assembly technology, applied in electrical components, telephone communications, branch equipment, etc., can solve problems such as easily damaged products and complex structures, and achieve the effects of avoiding damage, increasing the contact area, and facilitating observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

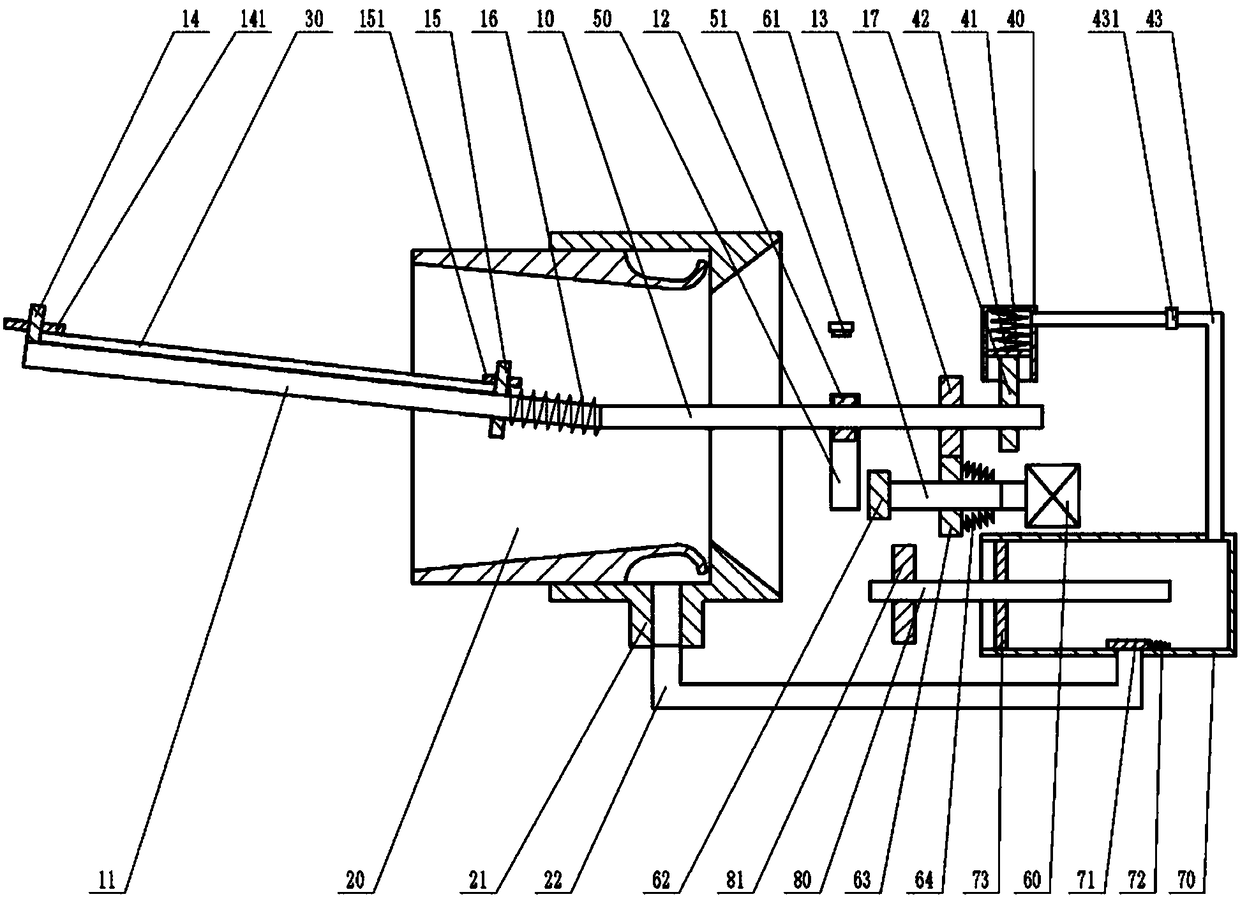

[0017] Instructions attached figure 1 The reference signs in include: horizontal rod 10, inclined rod 11, fourth gear 12, first rod 14, first gear 13, first pressing piece 141, second rod 15, second pressing piece 151, fourth spring 16. Cam 17, air amplifier 20, compressed gas inlet 21, second air pipe 22, mobile phone assembly 30, pump 40, second spring 41, piston 42, first air pipe 43, one-way exhaust valve 431, rack 50 , single-control switch 51, motor 60, rotating shaft 61, electromagnet 62, second gear 63, first spring 64, air reservoir 70, sealing plate 71, third spring 72, pressure plate 73, threaded rod 80, third gear 81 .

[0018] Such as figure 1 As shown, the mobile phone component welding detection device includes a frame, an air amplifier 20, a gas storage unit, a control unit, a rotating unit and a transmission unit. The air amplifier 20 is provided with a compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com