Calculation method for fatigue life of material sliding plate of material suction and discharge vehicle

A fatigue life and calculation method technology, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve problems such as difficulty in ensuring the accuracy of calculation results and calculation efficiency, and achieve excellent universality, accurate calculation, and calculation efficiency and high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

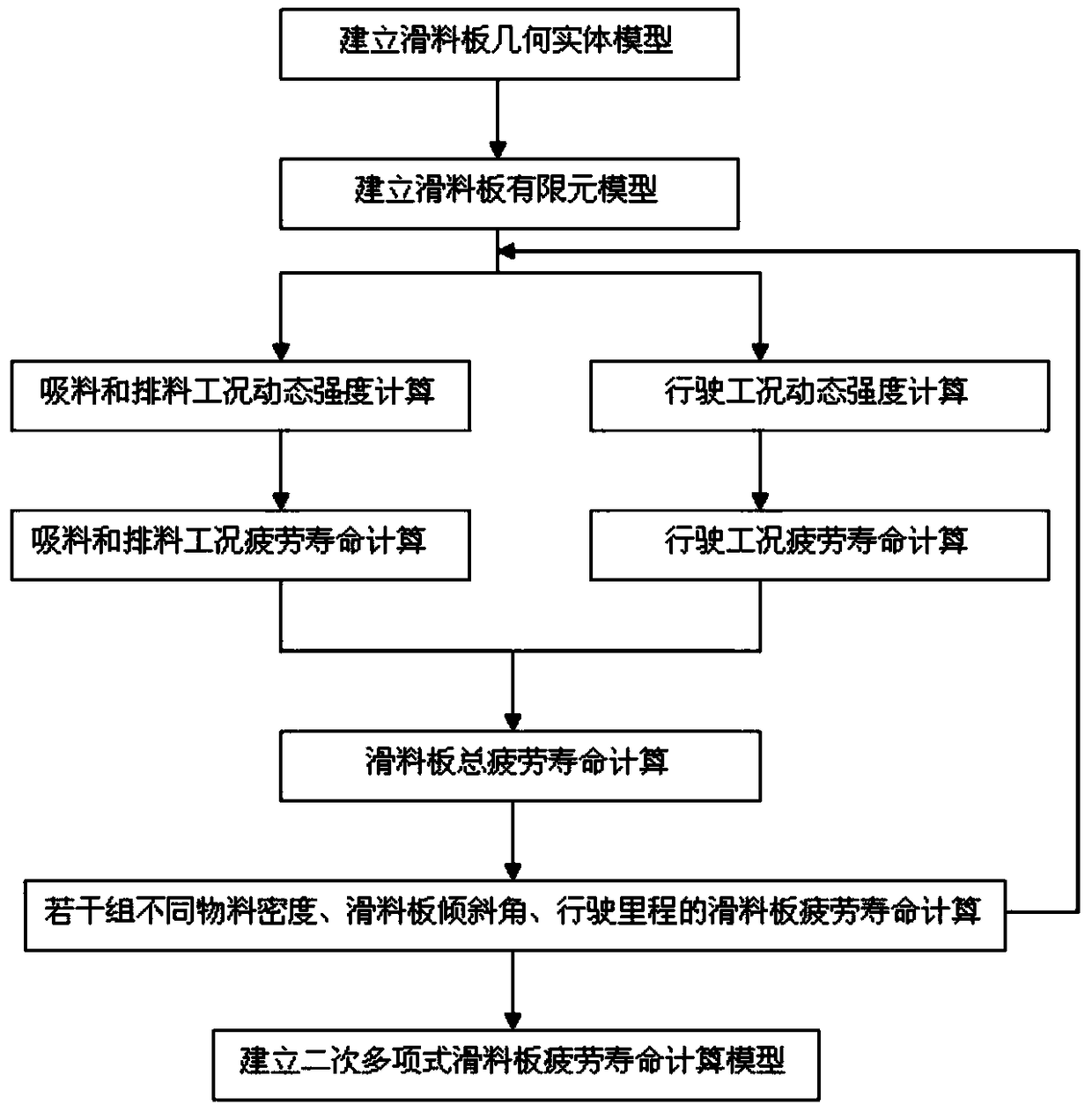

[0034] Such as figure 1 As shown, the present embodiment provides a method for calculating the fatigue life of the sliding plate of the material suction and discharge vehicle, which includes the following steps:

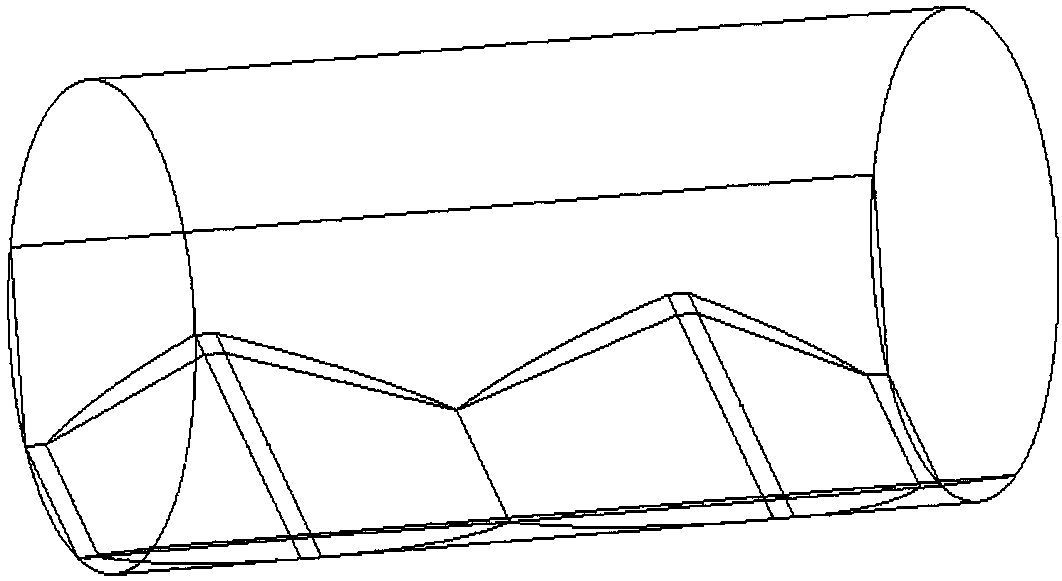

[0035] (1) Establish a 3D overall finite element model of the sliding sheet including the tank body, use 3D CAD software to establish a 3D overall geometric model of the sliding sheet including the tank body, import the geometric model of the sliding sheet into the finite element software, and define the unit type , set the material parameters, define the meshing parameters and carry out meshing, where the joint between the sliding plate and the tank body is finely meshed, and the fine meshing refers to reducing the mesh to the original mesh size 50% to 70%.

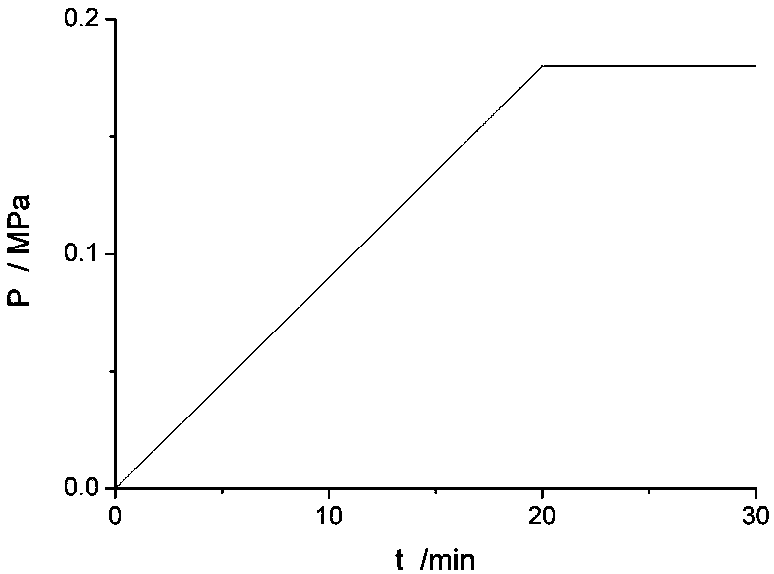

[0036] (2) Calculate the fatigue life of the sliding plate under the material suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com