Multi-gear steady-supporting ball valve controlled by double rocker

A multi-position, ball-supporting technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of inflexible closing, valve seat system failure, poor stability of the pressing link, etc., and achieve a compact structure. Stable, reduced parts, good preload performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

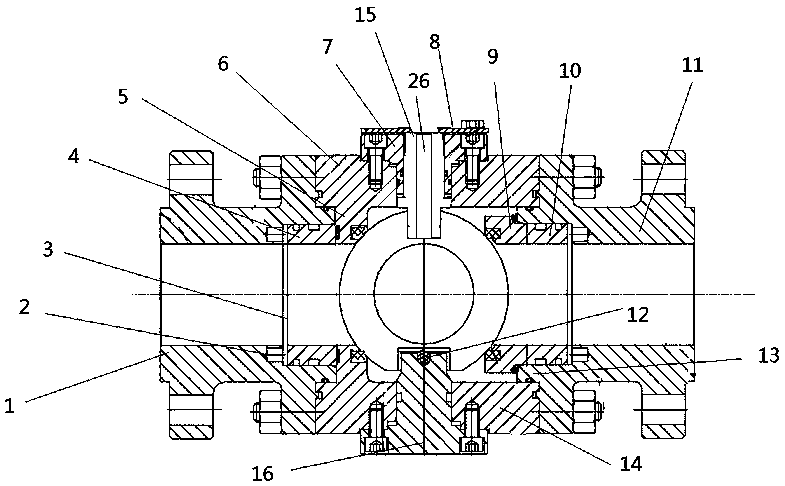

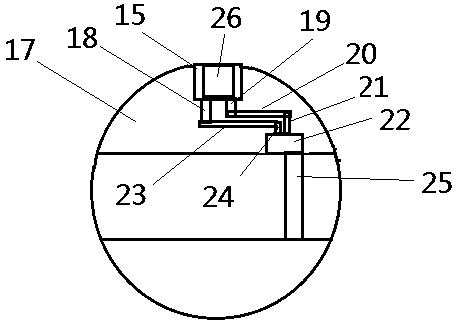

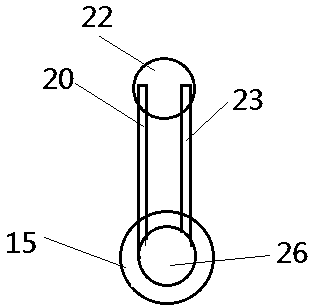

[0034] As shown in the figure: a double rocking multi-position stable support ball valve, including a left flange, a pretensioner, a spacer ring, a left pressure ring, a convex valve seat, an upper valve body, a shaft sleeve, a connecting plate, and a right valve seat , right pressure ring, pressure plate flange, lower spring, left protrusion, lower valve body, outer valve stem, lower valve shaft, ball, first long rod, first short rod, upper connecting rod, second long rod, Secondary shaft, lower connecting rod, second short rod, auxiliary valve plate, inner valve stem; the left flange is located on the left side of the upper and lower valve bodies, and the pressure plate flange is located on the right side of the upper and lower valve bodies, The shaft sleeve is fixed on the upper side of the upper valve body by screws, and the connecting plate is fixed on the upper side of the shaft sleeve to connect the driving device. There is a through hole in the shaft sleeve, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com