Hydrophobic and oleophobic coating liquid for automobile glass

An automotive glass, sparse coating technology, applied in the coating and other directions, can solve the problems of endangering the safety of driving at night, jumping wipers, glare, etc., and achieve the effects of preventing light reflection, increasing effective time, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

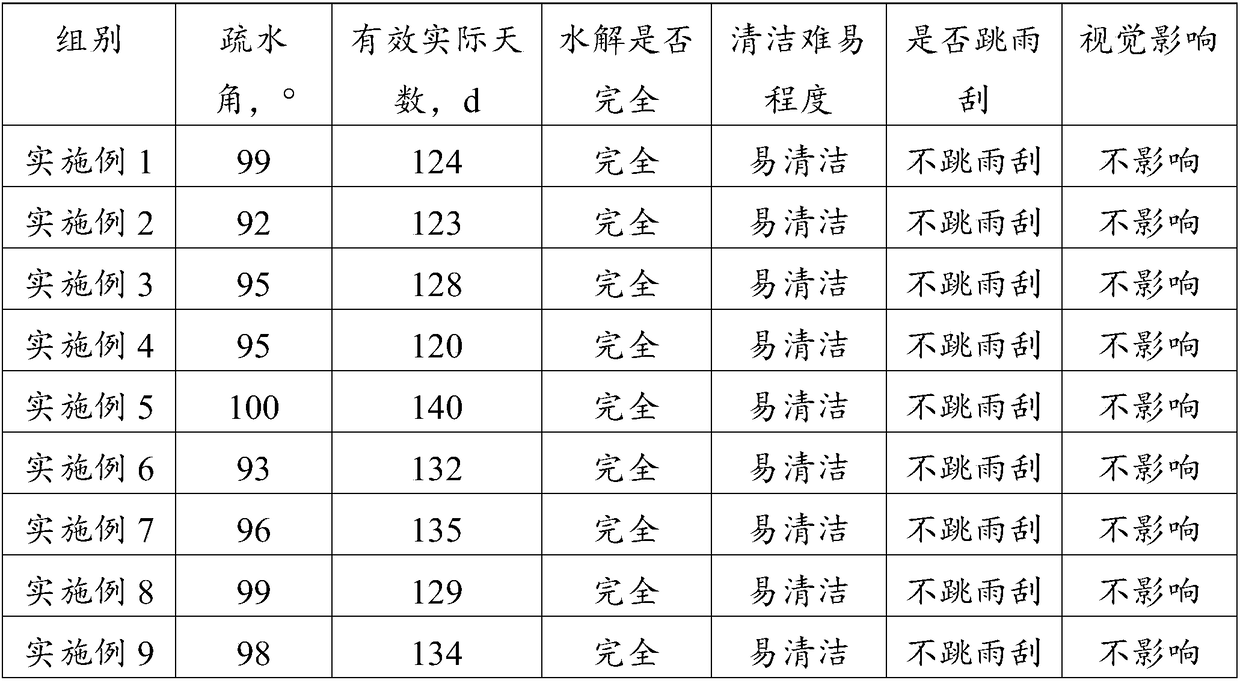

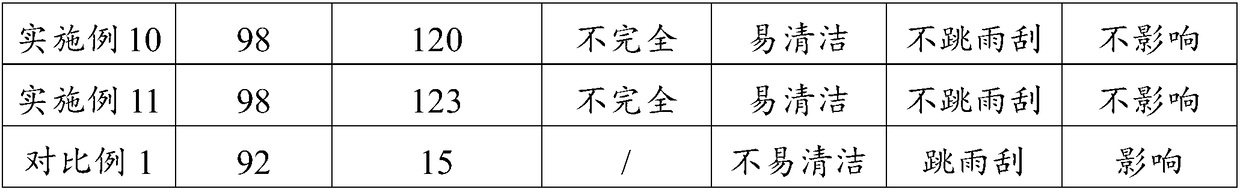

Examples

Embodiment 1

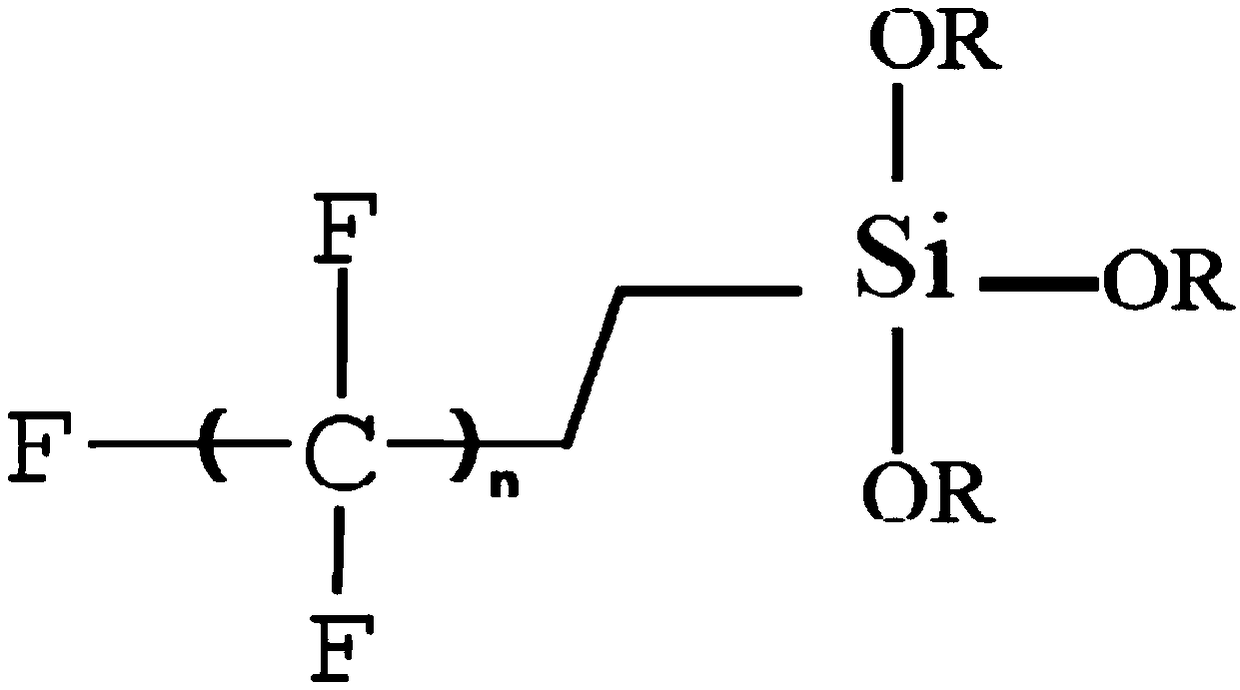

[0051] A kind of embodiment of the oil-water amphobic coating liquid that is used for automobile glass of the present invention, the oil-water amphobic coating liquid that is used for automobile glass described in the present embodiment comprises following components by weight:

[0052] 5 parts of fluorosilane coupling agent, 15 parts of deionized water, 2 parts of catalyst, 72.5 parts of solvent and 0.5 parts of auxiliary agent;

[0053] The fluorosilane coupling agent is heptadecafluorodecyltriethoxysilane;

[0054] The catalyst is acetic acid;

[0055] Described solvent is the mixture of Virahol and Dipropylene Glycol Methyl Ether; Described Virahol is 50 parts by weight, and Dipropylene Glycol Methyl Ether is 22.5 parts by weight;

[0056] The auxiliary agent is polyether modified polydimethylsiloxane.

[0057] The preparation method of the oil-water amphobic coating liquid for automobile glass described in the present embodiment comprises the following steps:

[0058] ...

Embodiment 2

[0062] An embodiment of the oil-water amphobic coating liquid used for automotive glass according to the present invention, the difference between this embodiment and Embodiment 1 is only the difference in the type of fluorosilane coupling agent, the fluorosilane described in this embodiment The coupling agent is tridecafluorooctyltriethoxysilane.

[0063] The preparation method of the oil-water amphobic coating solution for automobile glass described in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0065] An embodiment of the oil-water amphobic coating liquid used for automotive glass according to the present invention, the difference between this embodiment and Embodiment 1 is only the difference in the type of fluorosilane coupling agent, the fluorosilane described in this embodiment The coupling agent is heptadecafluorooctyltrimethoxysilane.

[0066] The preparation method of the oil-water amphobic coating solution for automobile glass described in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com