Preparation method of easily-degradable environmentally-friendly plastic

An environmentally friendly plastic and easy-to-degrade technology, applied in the field of polymer materials, can solve the problems of not being able to use daily necessities, etc., and achieve the effects of simple and easy preparation process, stable storage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

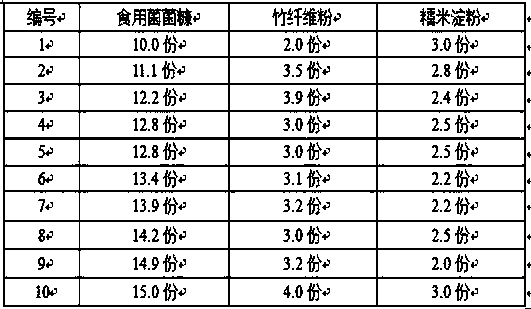

[0042] Example 1 Preparation of biological components

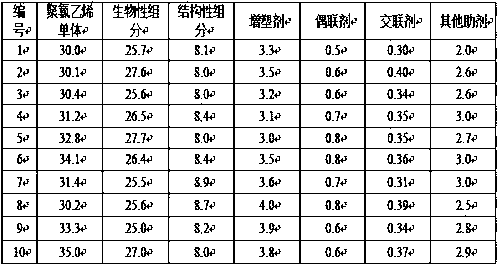

[0043] The biological components and mass parts are listed as follows:

[0044]

[0045] The preparation method of the biological component is:

[0046]Grind the chaff of edible fungi to an average particle size of 1.6-1.8 mm, mix it with bamboo fibers with an average length of 1.5 mm and a diameter of 3.8 μm, mix evenly, and dry in an oven at 85°C until the water content is lower than 20%. Secondary crushing, crushing until the average particle size of the mixture is less than 3 μm, performing secondary drying in an oven at 85°C until the water content is less than 10%, and finally mixing with glutinous rice starch evenly, and drying three times in an oven at 44°C until the water content of the mixture is low At 5%, the desired biological components were obtained.

[0047] Among the biological components, the humidity of edible fungus chaff is relatively high, but the drying efficiency is low when it is dried alone....

Embodiment 2

[0049] Example 2 Structural components

[0050] In this example, the iron tailings powder obtained in the gravity separation ore dressing process is used as a structural component. The iron tailings powder has an iron content of less than 2% and the average particle size of the iron tailings powder is 0.1 μm ( Iron tailings powder source: Hubei Daye).

Embodiment 3

[0051] Embodiment 3 Preparation of environmentally friendly plastics

[0052] Environmentally friendly plastic raw material components and mass parts are shown in the following list, wherein the polyvinyl chloride monomer is a commercially available product, the biological component adopts the raw material numbered 8 in Example 1, and the structural component adopts the material in Example 2 The raw material and the plasticizer are mixed with dioctyl phthalate, orthophosphate and ethylene glycol at a mass ratio of 2:0.22:0.57. The coupling agent is a monoalkoxypyrophosphate titanate coupling agent (commercially available), and the crosslinking agent is dicumyl peroxide, diethylenetriamine, and zinc oxide at a mass ratio of 1:1.15: 0.053 mixed. Other additives are a mixture of defoamers, lubricants, surfactant accelerators, and ultraviolet absorbers. The defoamer is silicone defoamer (commercially available), and the surfactant accelerator is sodium lauroyl glutamate. The age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com