High belite sulphoaluminate cement based disturbance-resistance concrete for rush repair and preparation method of high belite sulphoaluminate cement based disturbance-resistance concrete

A technology of sulfoaluminate and concrete, which is applied in the field of high-belite sulfoaluminate cement-based anti-disturbance concrete for emergency repair, and can solve the problems of reduced safety and durability, damage to mechanical properties and durability, and increased damage Disturbance damage and other problems, to achieve excellent anti-disturbance performance, good economic and social benefits, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

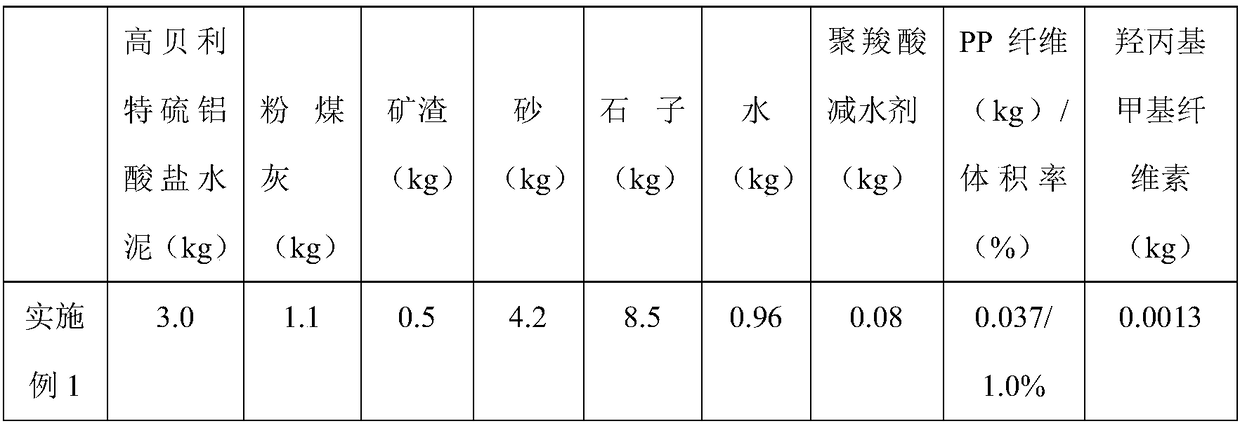

[0032] Embodiment 1: raw material and proportioning are as follows

[0033]

[0034] Table 1 Proportion of high belite sulphoaluminate cement-based anti-disturbance concrete 1

[0035] The following is the test report of the obtained high belite sulphoaluminate cement-based anti-disturbance concrete for emergency repair

[0036] Test items

[0037] The disturbed period of the anti-disturbance concrete under this ratio is only 8 minutes, which reduces the probability of concrete being disturbed; there is no crack on the surface of the test piece; the early and late strength performance is excellent, and the compressive strength can reach 20.2MPa 2h after being disturbed. The flexural strength can reach 6.3MPa, and there is no loss of strength compared with the undisturbed test piece, which meets the technical requirements for quick repair and opening to traffic.

Embodiment 2

[0039] Raw materials and proportions are as follows

[0040] Table 2 Proportion 2 of high belite sulphoaluminate cement-based anti-disturbance concrete

[0041]

[0042] The following is the test report of the obtained high belite sulphoaluminate cement-based anti-disturbance concrete for emergency repair

[0043] Test items

[0044] The disturbed period of the anti-disturbance concrete under this ratio is only 9 minutes, which reduces the probability of concrete being disturbed; there is no crack on the surface of the specimen; the early and late strength performance is excellent, and the compressive strength can reach 22.9MPa 2h after being disturbed. The flexural strength can reach 7.2MPa, and there is no loss in strength compared with the undisturbed test piece, which meets the technical requirements for quick repair and opening to traffic.

Embodiment 3

[0046] Raw materials and proportions are as follows

[0047] Table 3 High Belite sulfoaluminate cement-based anti-disturbance concrete ratio 3

[0048]

[0049] The following is the test report of the obtained high belite sulphoaluminate cement-based anti-disturbance concrete for emergency repair

[0050] Test items

Test results

Initial setting time

21min

final setting time

29min

23.5MPa

1d compressive strength

43.7MPa

3d compressive strength

55.1 MPa

28d compressive strength

61.4MPa

6.9MPa

1d flexural strength

12.7MPa

3d flexural strength

17.8 MPa

surface condition

no cracks

[0051] The disturbed period of the anti-disturbance concrete under this ratio is only 9 minutes, which reduces the probability of concrete being disturbed; there is no crack on the surface of the specimen; the early and late strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com