Preparation method of pore material, marble-imitated pore brick and preparation method thereof

A technology of imitating marble and holes, applied in the field of architectural ceramics, can solve the problems of difficulty in effectively restoring the effect of holes, the lack of plasticity of the pore-forming agent, and low controllability, and achieve the effect of rich hole effects, good skeleton feeling, and enhanced plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

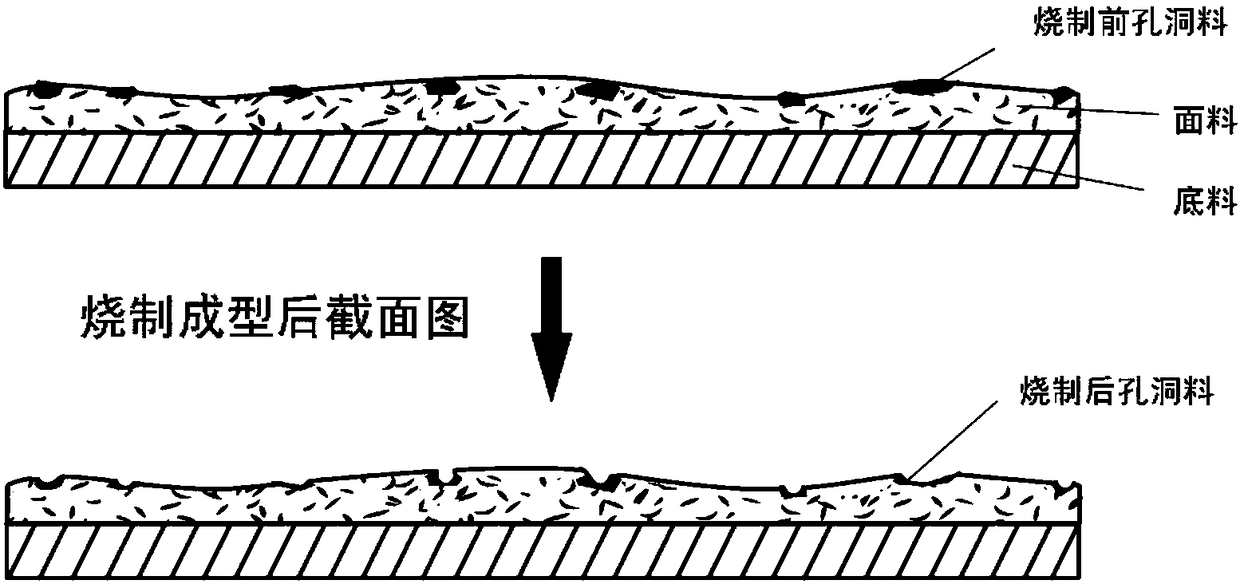

[0029] Embodiment - a kind of preparation method of imitation marble hole brick

[0030] 1. Preparation of hole material:

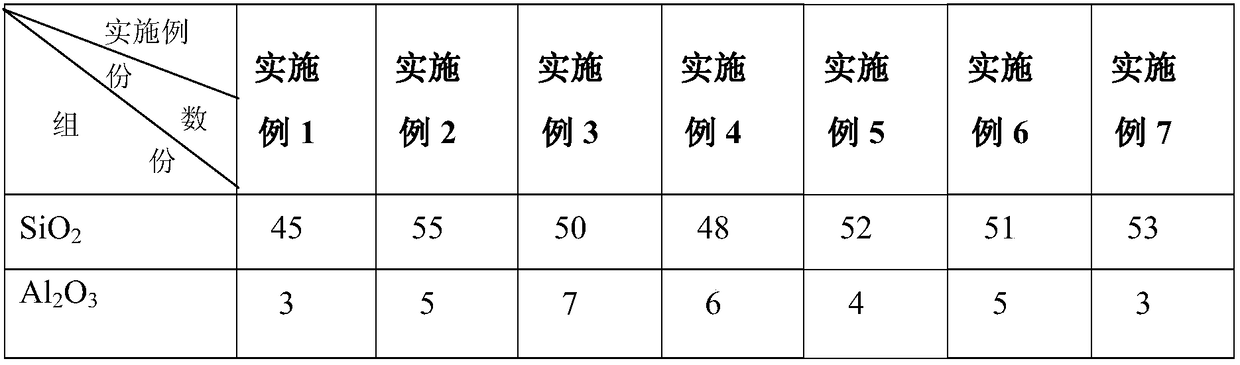

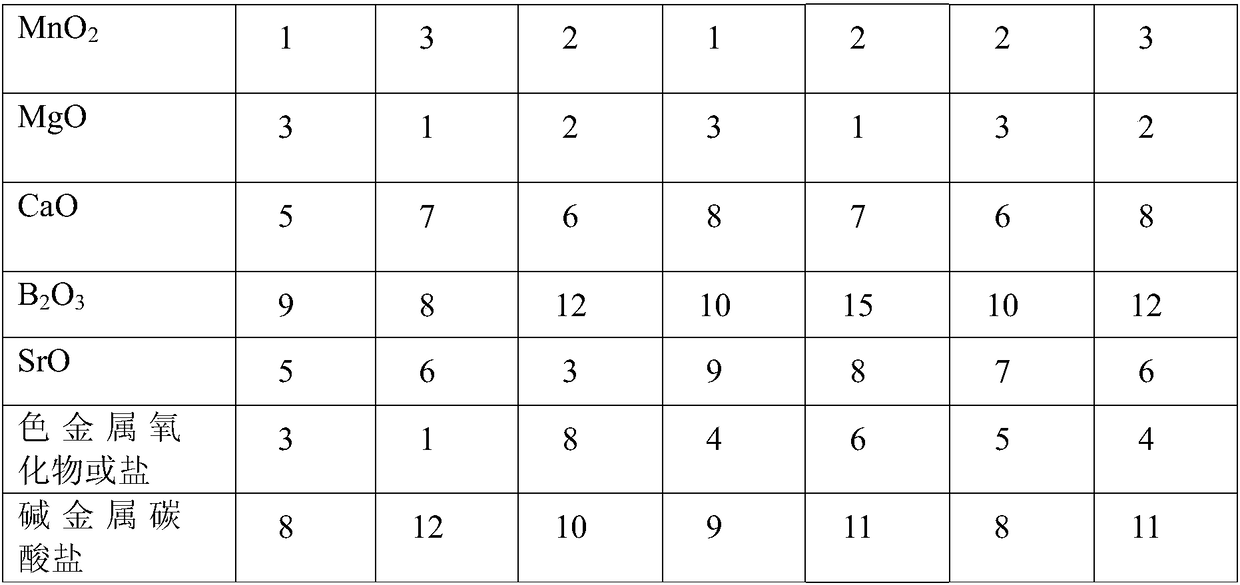

[0031] a. 45-55 parts of SiO in parts by weight ratio 2 , 3-7 parts Al 2 o 3 , 1-3 parts of MnO 2 , 1-3 parts of MgO, 5-8 parts of CaO, 8-15 parts of B 2 o 3 , 3-9 parts of SrO, 1-8 parts of colored metal oxides or salts and 8-12 parts of alkali metal carbonate are mixed to form a porous material frit, and crushed to obtain a porous material frit powder;

[0032] Among them, colored metal oxides or salts include lead chromate, zinc chromate, cadmium sulfide, hydrated iron oxide, potassium dichromate, iron oxide, dichromium oxide, ferrous sulfate, copper oxide, copper sulfate and dichromate Any one or more of vanadium; the alkali metal carbonates include Li 2 CO 3 、K 2 CO 3 、KHCO 3、Na 2 CO 3 and NaHCO 3 any one or more of

[0033] b. Mix 20-40% hole material frit powder, 20-30% epoxy resin, 30%-50% thinner and 1-5% curing agent in weight per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com