Netlike SiO2 coated sol, and preparation method and application thereof

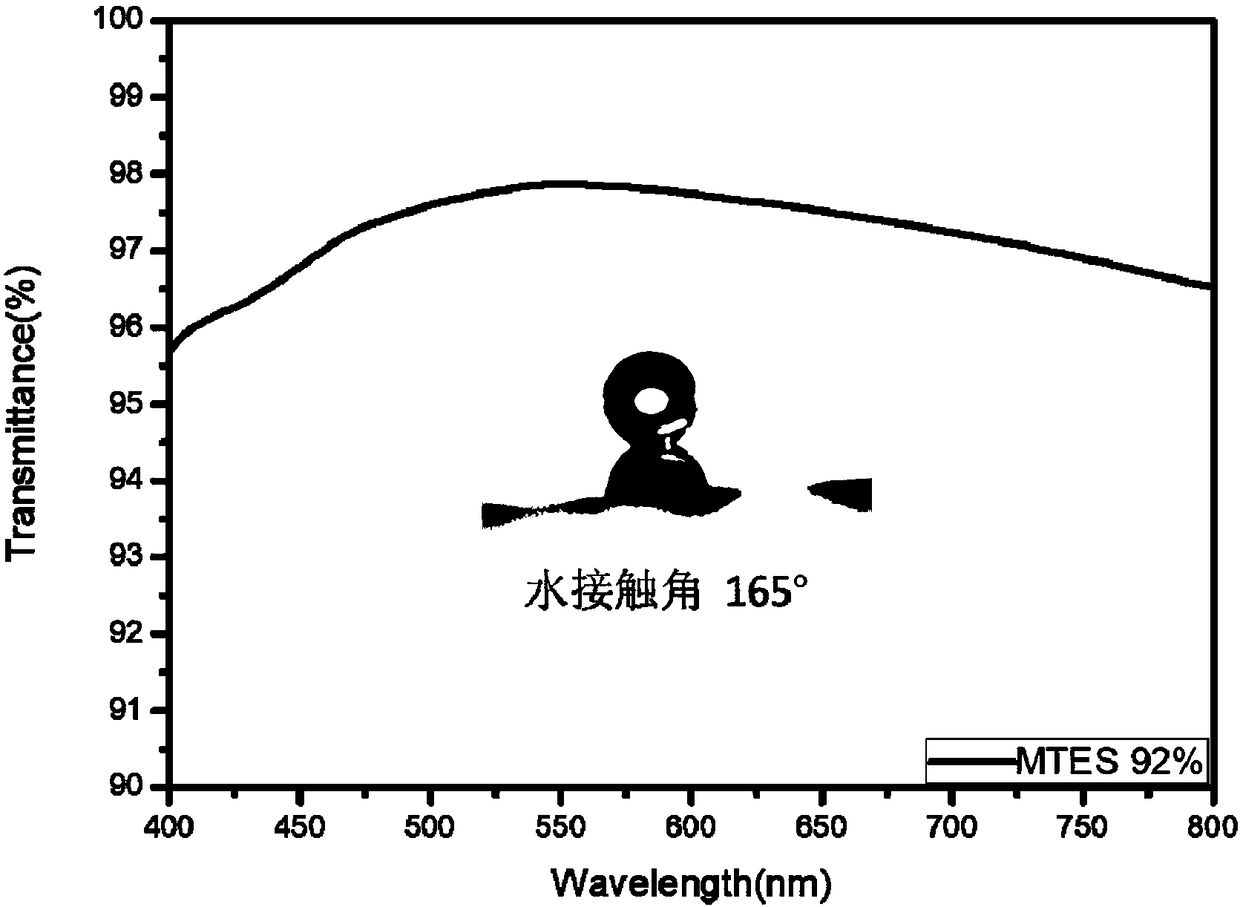

A network-like, sol technology, applied in chemical instruments and methods, inorganic chemistry, coatings, etc., can solve the problems of complex phase separation technology, low chemical vapor deposition rate, limited use range, etc., to ensure light transmittance and Hydrophobicity, increase light transmittance and mechanical properties, ensure the effect of film-forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

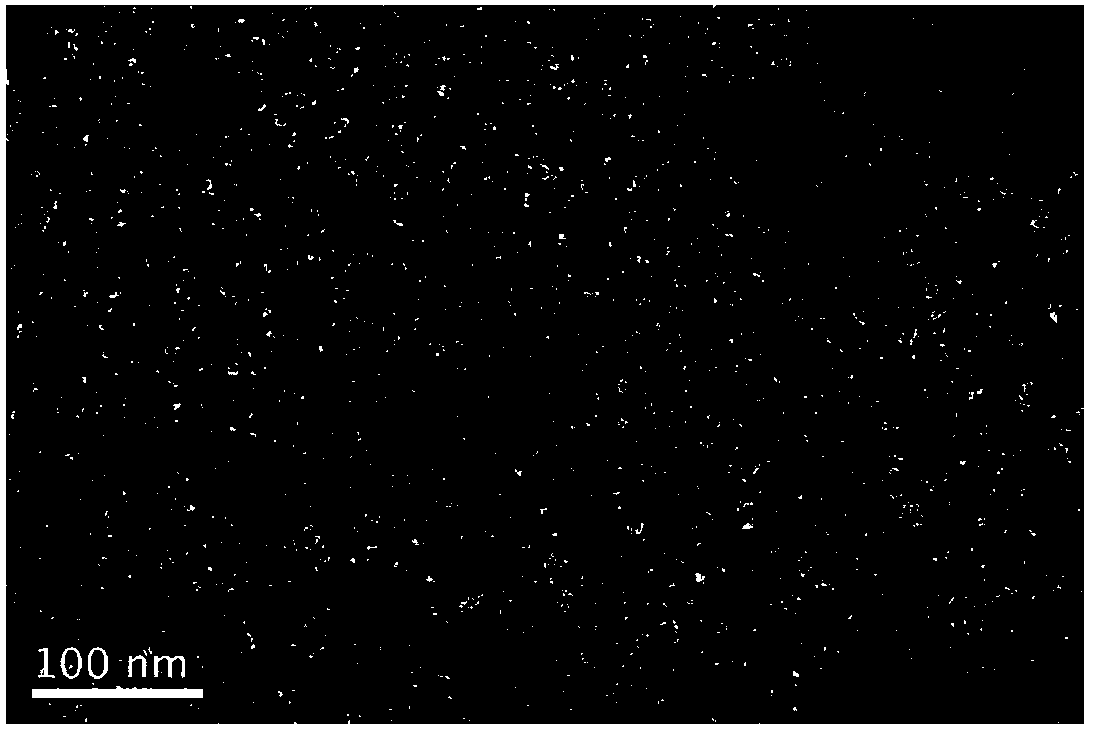

[0027] Network SiO 2 The preparation method of coating sol specifically comprises the following steps:

[0028] (1) At room temperature, take 10mL of methanol and add it to the reaction vessel, then add 0.4mL of MTES and 0.6mL of TMOS dropwise while stirring. After the dropwise addition is completed and stirred evenly, TMOS and MTES of the methanol system are obtained Mix well.

[0029] (2) Add 0.4mL of oxalic acid solution dropwise while stirring in the TMOS and MTES homogeneous mixture of the methanol system prepared in step (1), its concentration is 0.01mol / L, and stir at room temperature for 0.5h, then place in Aged at room temperature for 24 hours to obtain the first aged product.

[0030] (3) Add 0.2mL of ammonia water and 0.1mL of distilled water dropwise to the first aging product prepared in step (2) successively while stirring. Secondary compounds.

[0031] (4) Add 11 mL of methanol to the gel-like second aging product obtained in step (3), and obtain a sol after u...

Embodiment 2

[0038] Network SiO 2 The preparation method of coating sol specifically comprises the following steps:

[0039] (1) At room temperature, take 11mL of methanol and add it to the reaction vessel, then add 0.95mL of MTES and 0.05mL of TMOS dropwise while stirring. After the dropwise addition is completed and stirred evenly, TMOS and MTES of methanol system are obtained Mix well.

[0040] (2) Add 1 mL of oxalic acid solution dropwise while stirring to the homogeneous mixture of TMOS and MTES in the methanol system prepared in step (1), the concentration is 0.01mol / L, and stir at room temperature for 0.5h, then place at room temperature Aged for 24 hours to obtain the first aged product.

[0041] (3) Add 0.58mL of ammonia water and 0.4mL of distilled water dropwise to the first aged product prepared in step (2) successively while stirring, after stirring for 0.5h, place it at room temperature to age for 8 days to obtain a gel-like Second aging.

[0042] (4) Add 13 mL of methano...

Embodiment 3

[0049] Network SiO 2 The preparation method of coating sol specifically comprises the following steps:

[0050] (1) At room temperature, take 12mL of methanol and add it to the reaction vessel, then add 0.8mL of MTES and 0.2mL of TMOS dropwise while stirring. After the dropwise addition is completed and stirred evenly, TMOS and MTES of the methanol system are obtained Mix well.

[0051] (2) Add 1.6mL of oxalic acid solution dropwise while stirring in the TMOS and MTES homogeneous mixture of the methanol system prepared in step (1), its concentration is 0.01mol / L, and stir at room temperature for 0.5h, then place in Aged at room temperature for 24 hours to obtain the first aged product.

[0052] (3) Add 0.8mL of ammonia water and 0.6mL of distilled water dropwise to the first aged product prepared in step (2) successively while stirring, after stirring for 30min, place it at room temperature for aging for 8 days, and obtain a gel-like Secondary compounds.

[0053] (4) Add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com