Preparation method of high-efficiency water purifying activated carbon

A technology of activated carbon and water purification, applied in the field of activated carbon, can solve the problems of incomplete purification and unsatisfactory water purification effect, achieve good water purification effect, enhance water quality purification effect, and improve adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

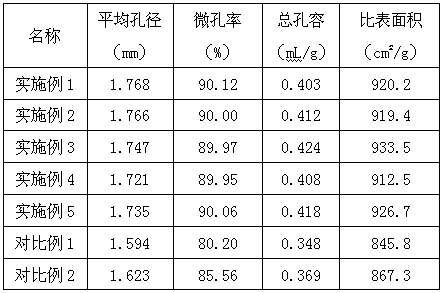

Examples

Embodiment 1

[0041] The preparation method of the high-efficiency water-purifying activated carbon of the present embodiment is composed of petroleum coke, raw coal, binder and activator, and the weight content of each component of the raw material is as follows:

[0042] Petroleum coke 55%;

[0043] Raw coal 35%;

[0044] Binder 15%;

[0045] Activator 5%;

[0046] Concrete preparation steps are as follows:

[0047] (1) Weighing petroleum coke and raw coal in proportion, crushing them, sieving to obtain petroleum coke particles and raw coal particles with a particle size of 3-5mm, and mixing the petroleum coke particles and raw coal particles evenly;

[0048] (2) Add binder in proportion to stir, mix and knead, and then briquetting by briquetting machine to obtain briquetting material;

[0049] (3) Put the briquette material into the carbonization furnace, heat up and carbonize under the protection of inert gas, and obtain the carbonized material;

[0050] (4) Crush the carbonized ma...

Embodiment 2

[0069] The preparation method of the high-efficiency water-purifying activated carbon of the present embodiment is composed of petroleum coke, raw coal, binder and activator, and the weight content of each component of the raw material is as follows:

[0070] Petroleum coke 60%;

[0071] Raw coal 25%;

[0072] Binder 10%;

[0073] Activator 5%;

[0074] Concrete preparation steps are as follows:

[0075] (1) Weighing petroleum coke and raw coal in proportion, crushing them, sieving to obtain petroleum coke particles and raw coal particles with a particle size of 3-5mm, and mixing the petroleum coke particles and raw coal particles evenly;

[0076] (2) Add binder in proportion to stir, mix and knead, and then briquetting by briquetting machine to obtain briquetting material;

[0077] (3) Put the briquette material into the carbonization furnace, heat up and carbonize under the protection of inert gas, and obtain the carbonized material;

[0078] (4) Crush the carbonized ma...

Embodiment 3

[0097] The preparation method of the high-efficiency water-purifying activated carbon of the present embodiment is composed of petroleum coke, raw coal, binder and activator, and the weight content of each component of the raw material is as follows:

[0098] Petroleum coke 60%;

[0099] Raw coal 28%;

[0100] Binder 8%;

[0101] Activator 4%;

[0102] Concrete preparation steps are as follows:

[0103] (1) Weighing petroleum coke and raw coal in proportion, crushing them, sieving to obtain petroleum coke particles and raw coal particles with a particle size of 3-5mm, and mixing the petroleum coke particles and raw coal particles evenly;

[0104] (2) Add binder in proportion to stir, mix and knead, and then briquetting by briquetting machine to obtain briquetting material;

[0105] (3) Put the briquette material into the carbonization furnace, heat up and carbonize under the protection of inert gas, and obtain the carbonized material;

[0106] (4) Crush the carbonized mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com