Automatic assembly and production equipment for ball valve

A technology for production equipment and automatic assembly, which is applied in the direction of metal processing equipment, assembly machines, workpiece clamping devices, etc., and can solve problems such as low efficiency and uneven assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

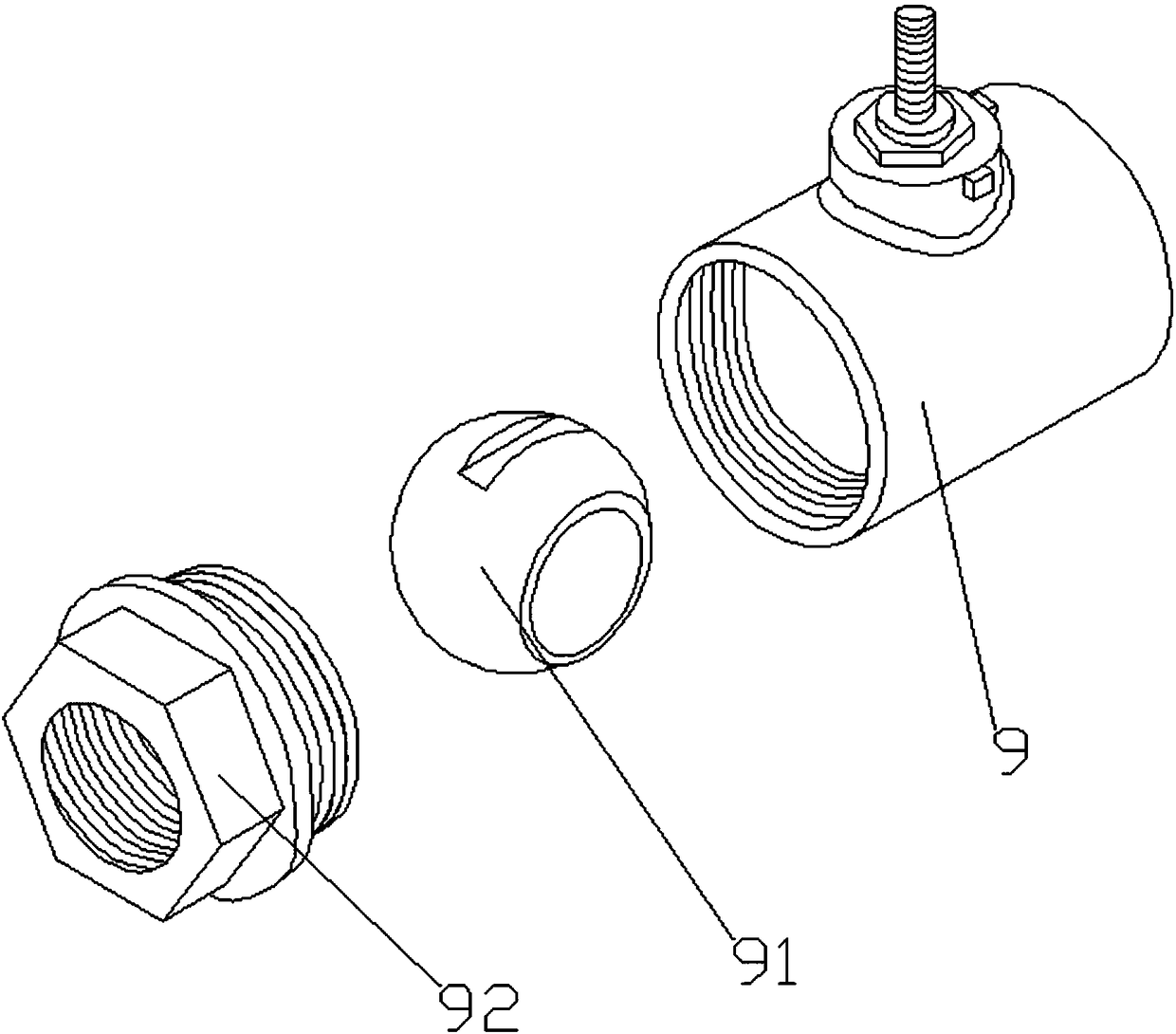

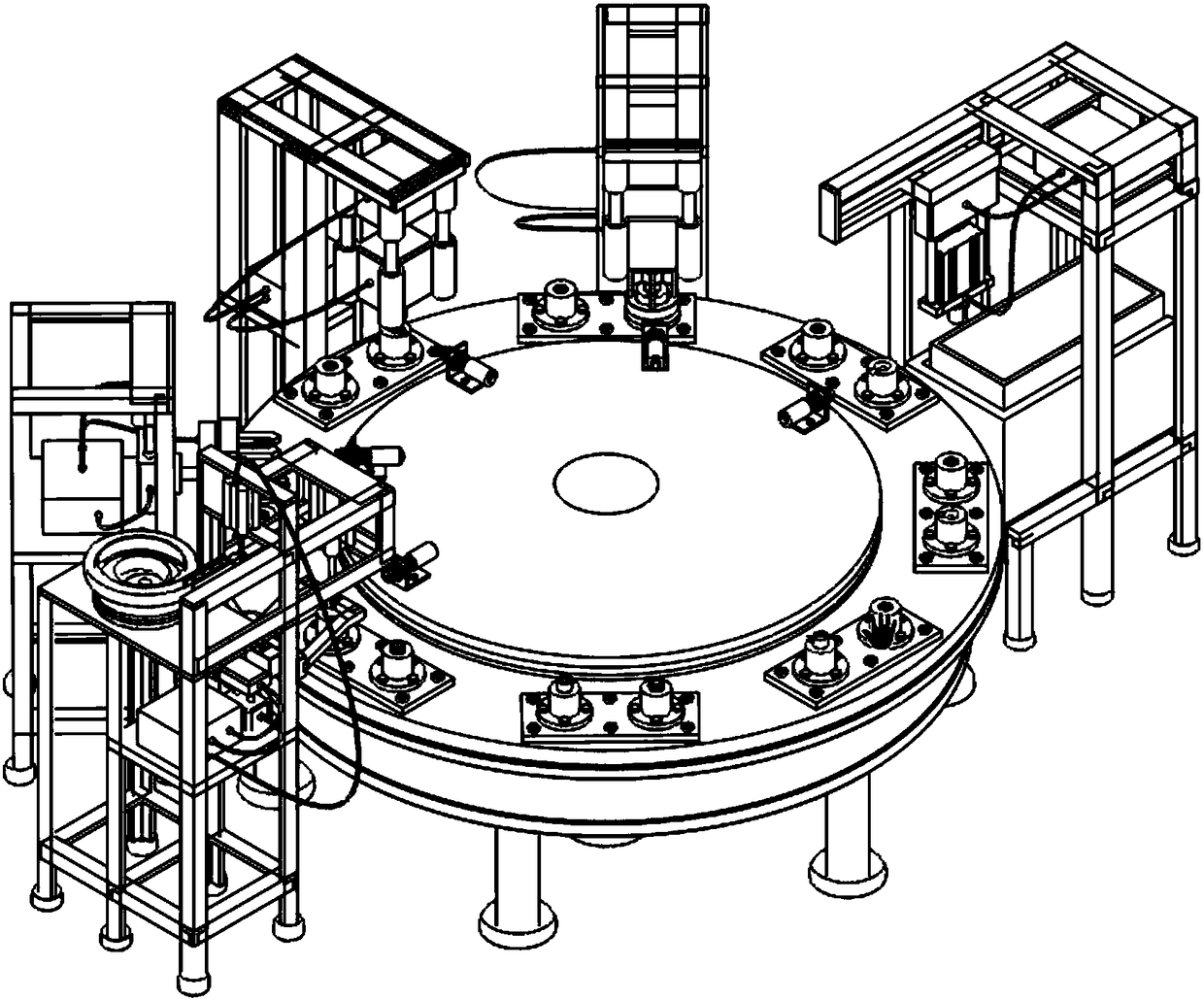

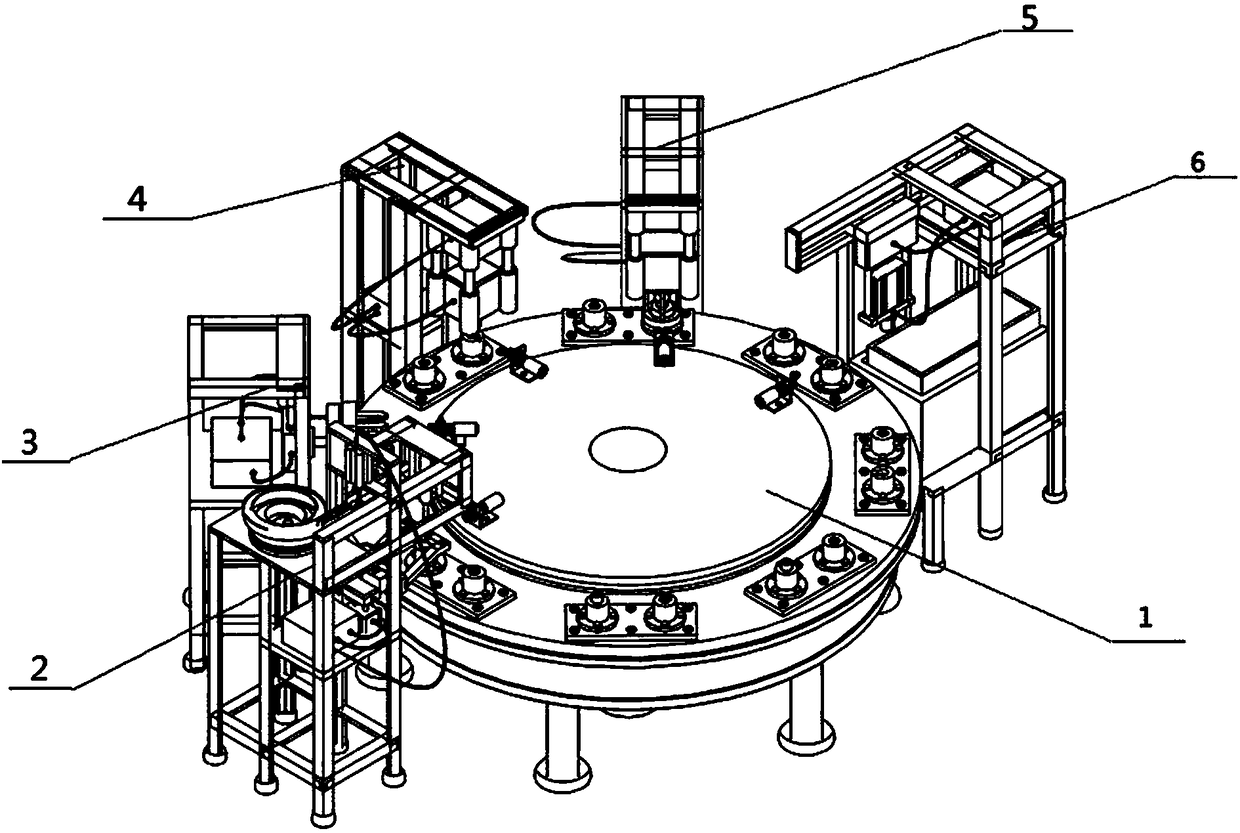

[0035] Such as Figure 1~Figure 14 As shown, the present invention discloses a ball valve automatic assembly production equipment, including a disc-type assembly line 1, the disc-type assembly line 1 is composed of a disc-type assembly line main body 101 and a disc-type assembly line servo that drives the disc-type assembly line main body 101 to rotate circularly. The drive system 105 consists of a disc-type assembly line servo drive system 105 including a rotary pneumatic component and a rotating shaft driven by the rotary pneumatic component to drive the disc-type assembly line main body 101 to rotate. The edges of the disc-type assembly line main body 101 are equidistantly arranged along the rotation direction. A plurality of ball valve component fixture devices 102, the ball valve component fixture device 102 includes a preset ball valve body, and a valve body fixture 1021 with the matching position of the ball valve body and the ball valve side screw cover facing upward, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com