Liquid reagent transferring and mixing apparatus

A mixing device and reagent technology, applied in the field of experimental equipment, can solve problems such as safety hazards and inconvenience, and achieve the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

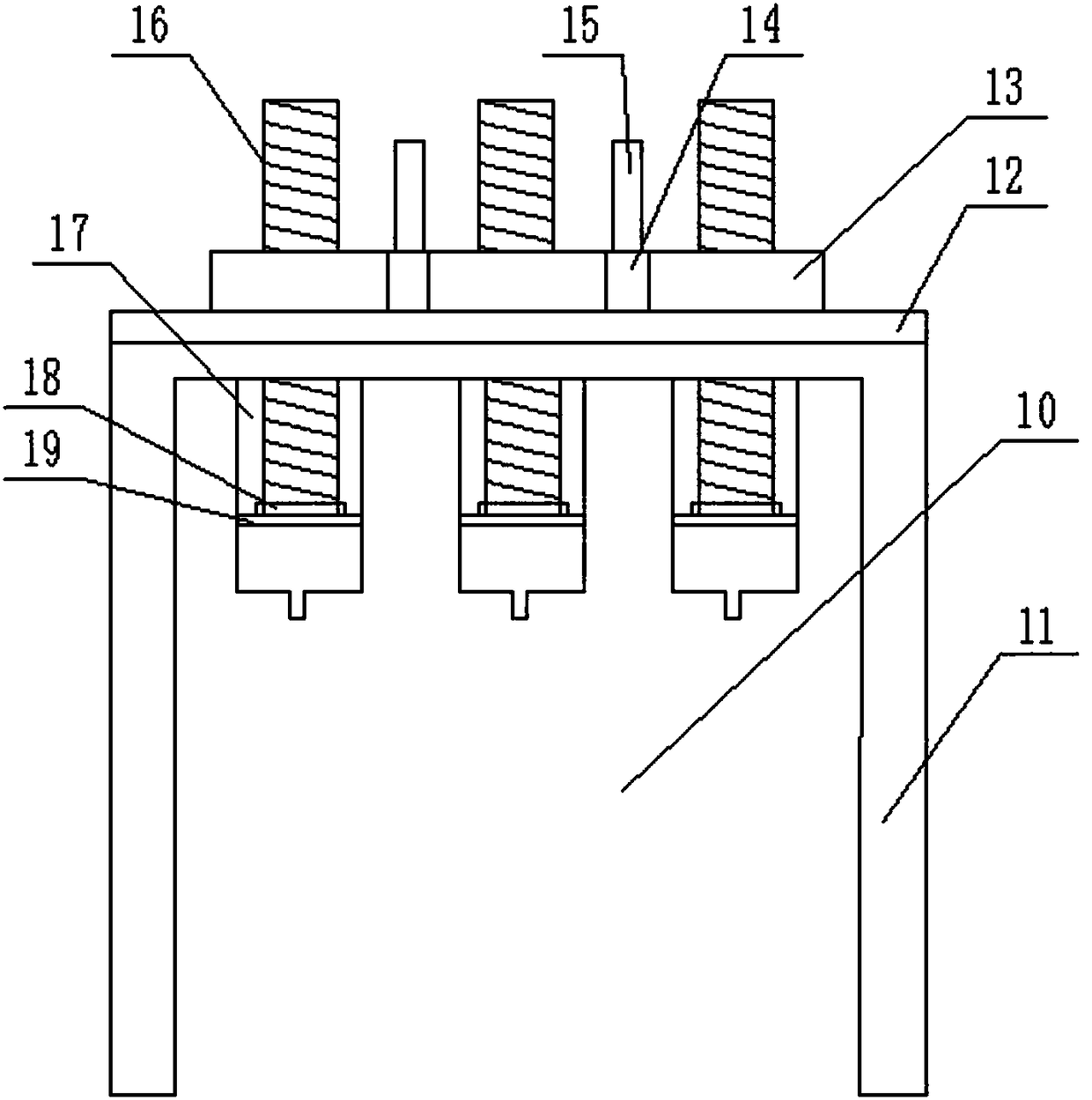

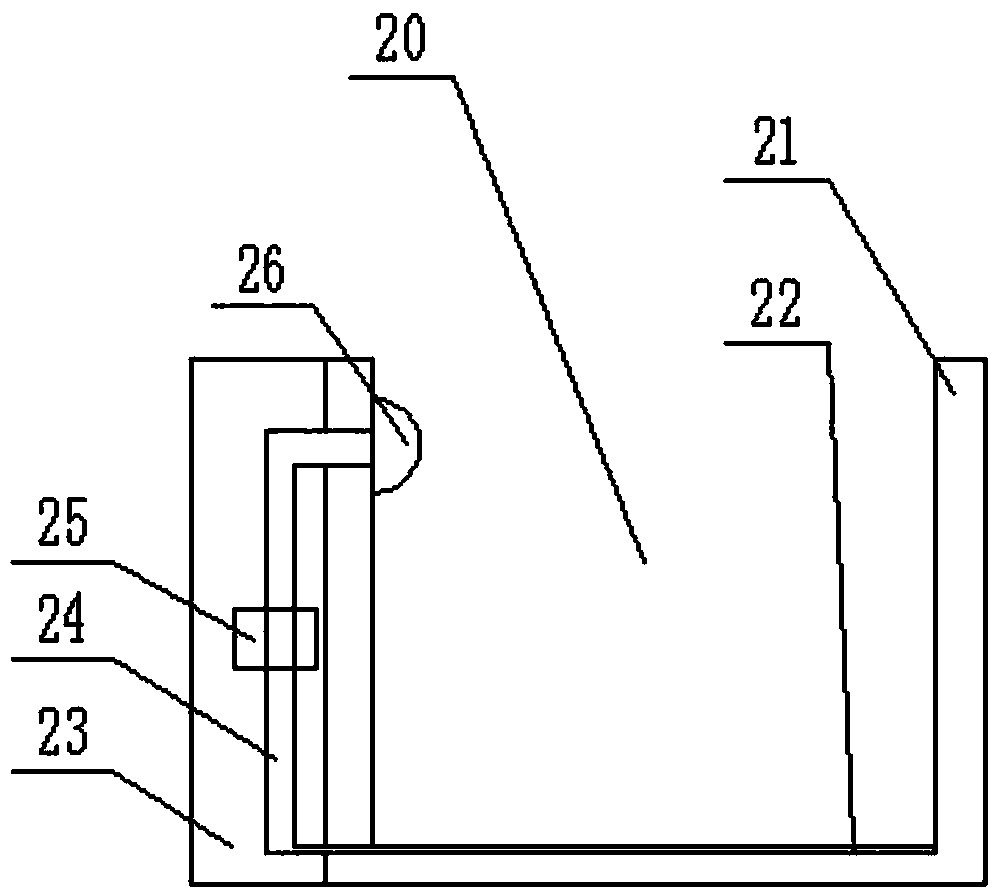

[0045] As a preferred embodiment, the mixing device 20 includes a cup body 21, a hollow bottom plate 22 is provided at the bottom of the cup body 21, and a set of vent holes 221 are provided on the hollow bottom plate 22, each of the vent holes 221 Each is provided with a PTFE air filter membrane, a storage chamber 23 is provided on one side of the cup body 21, and an air pump 25 is provided in the storage chamber 23. The air inlet pipe 26 of the air pump 25 is connected to the side wall of the cup body 21 On the upper side, the air outlet pipe 24 of the air suction pump 25 is connected to the hollow bottom plate 22, and a waterproof cover 27 is provided on the outside of the air inlet pipe 26, and the waterproof cover 27 is fixed on the inner wall of the cup body 21. The mixing device 20 is provided with a plurality of air outlet holes 221 at the bottom, and a PTFE air filter membrane is arranged in the air outlet 221. The PTFE air filter membrane is air-permeable and impermeab...

Embodiment 1

[0055] Example 1: Mixing of two liquid reagents in a ratio of 1:1

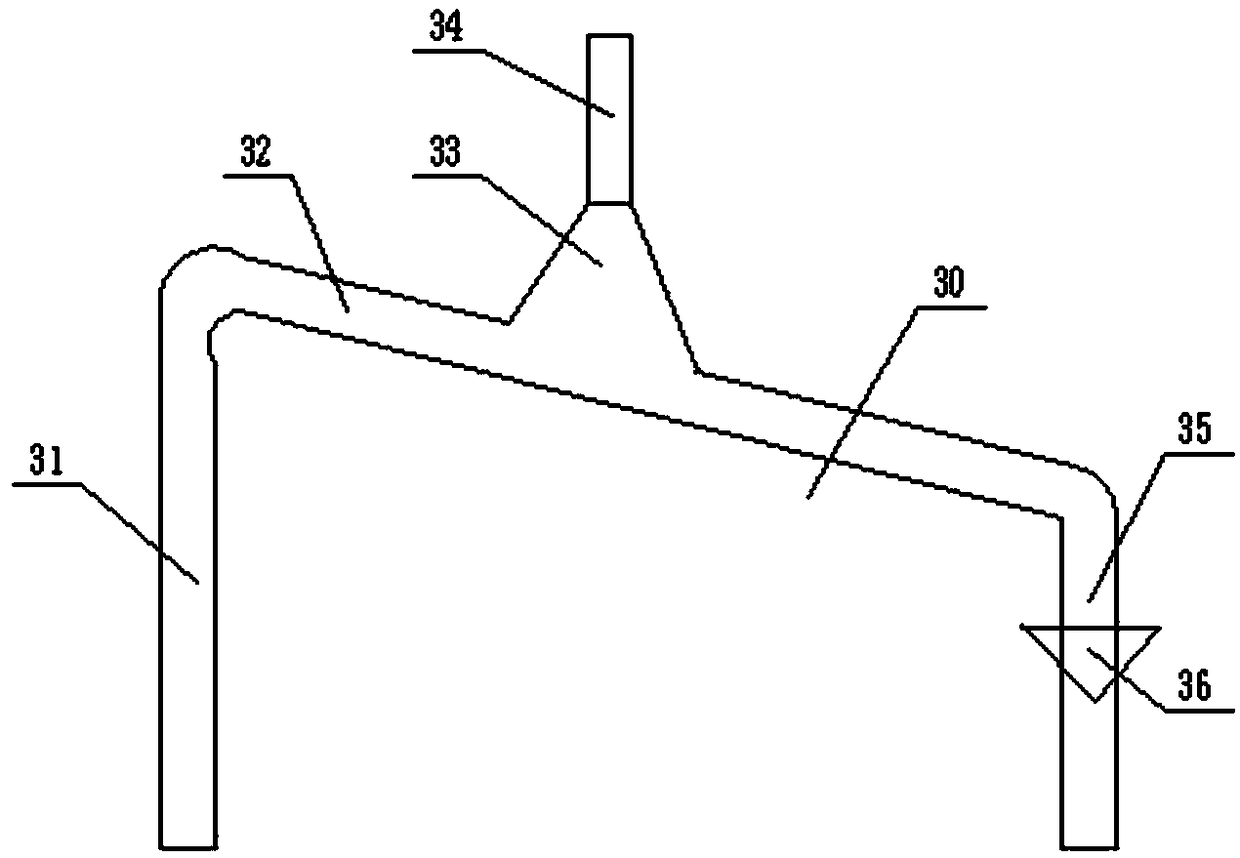

[0056] Such as Figure 4 As shown, at this time, the driving gear meshes with the first gear a, and the first gear a meshes with the first gear b through the second gear; the two pipes are installed in the above process and the driving gear is made by turning the handle or the stepping motor. Rotation drives the first gear a to rotate. The meshed second gear drives the first gear b to rotate, which drives the two lead screws to move upwards and drives the pistons to move upwards, so that the two different liquids in the two two pipes follow The ratio of 1:1 enters the cup. (In this embodiment, a and b are only used to distinguish the two first gears and are only applicable to this embodiment 1)

Embodiment 2

[0057] Example 2: Mixing of two liquid reagents in a ratio of 1:2

[0058] According to the process in Example 1, the two liquids are first transferred 1:1. During the transfer process, the liquid with a high transfer ratio is located at the end close to the driving gear to complete the 1:1 ratio transfer and record the rotation of the driving gear. Count, lift the second gear up by the handle, and fix the second gear to the fixed rod by the hook on the handle, and then turn the driving gear the same number of turns to complete the 1:2 liquid transfer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com