Surface-mounted support and multi-chip photoelectric device

A mounting type, conductive substrate technology, applied in the direction of electrical solid devices, electrical components, semiconductor devices, etc., can solve the problems of weak bonding force of insulating materials, poor heat dissipation effect, and difficulty in achieving low voltage, etc., to achieve the realization of solid crystal bonding wire Design, low bonding wire design, the effect of realizing voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

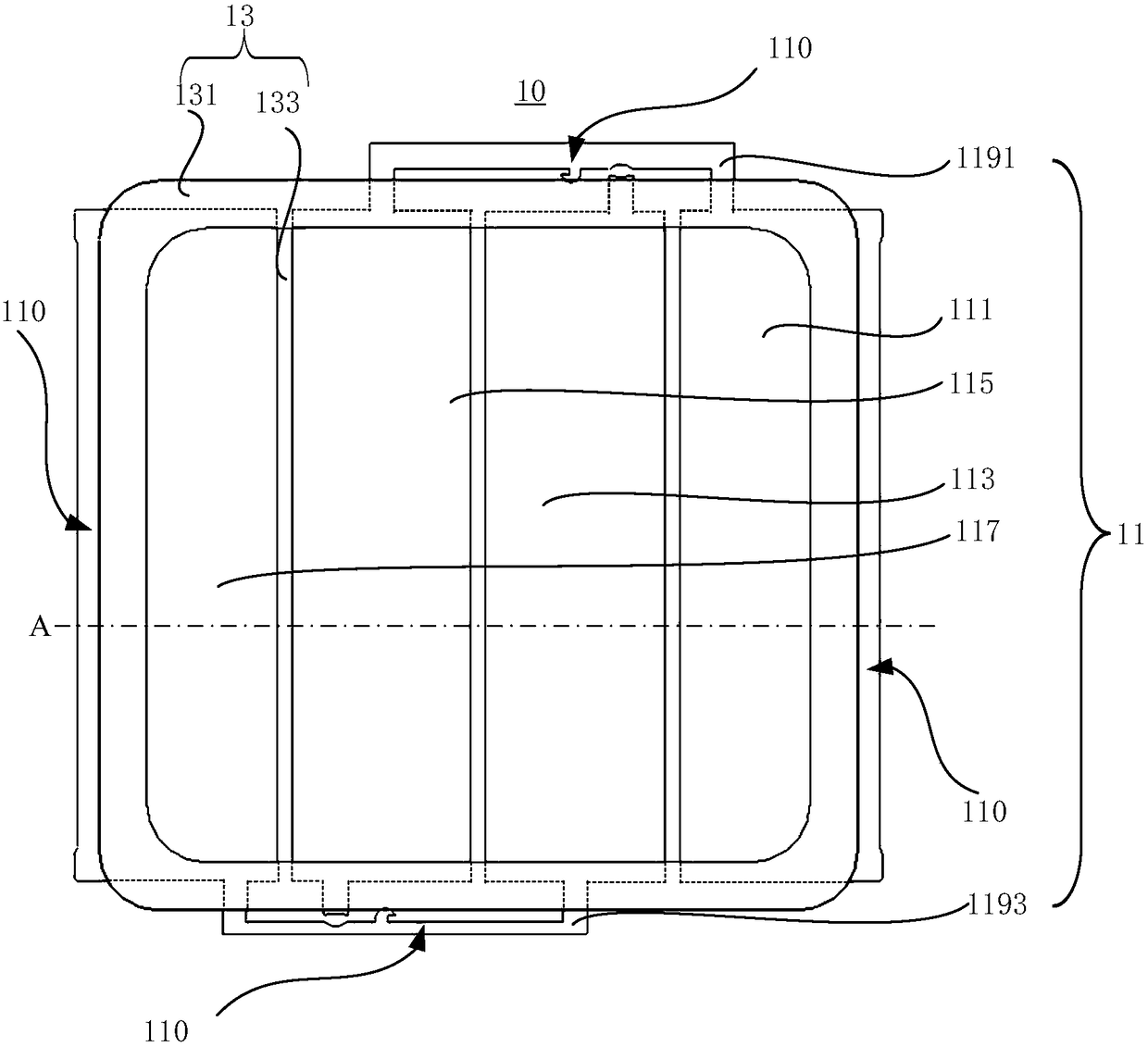

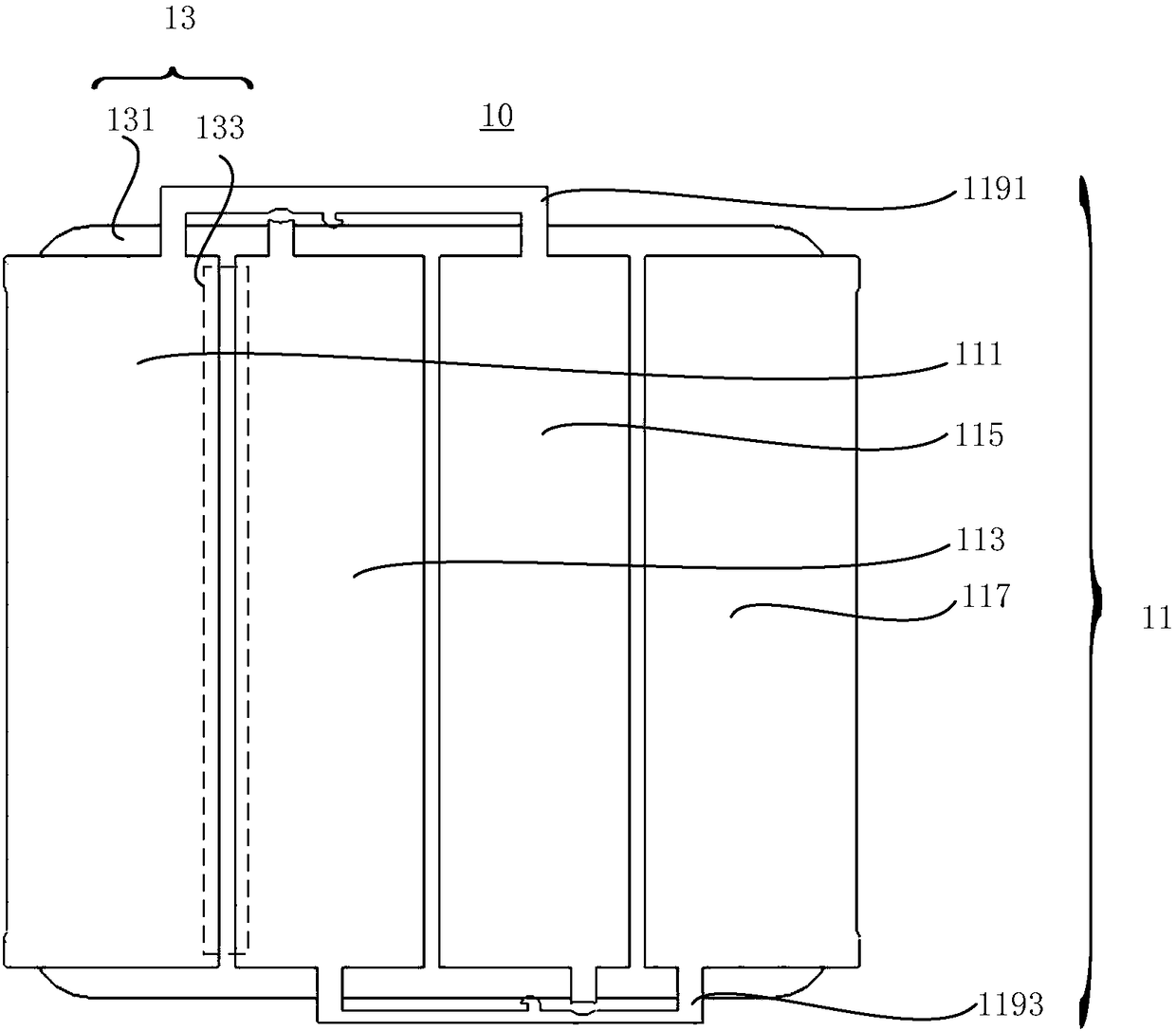

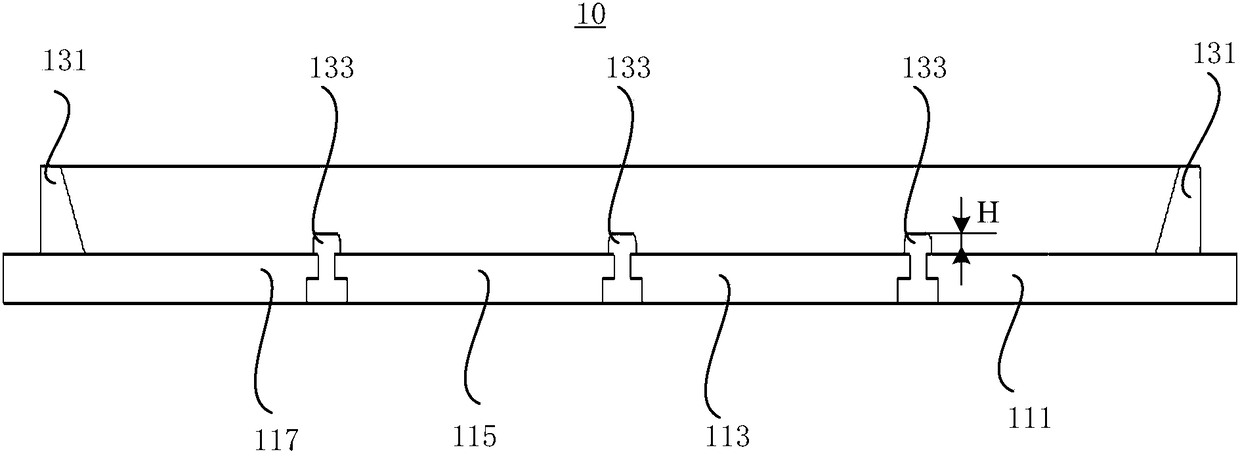

[0028] Such as Figure 1A , Figure 1B with Figure 1C As shown, a surface mount bracket 10 provided by the first embodiment of the present invention mainly includes: a conductive base 11 and an insulating material layer 13 .

[0029] Wherein, the conductive base 11 includes a plurality of connection pads, such as Figure 1A The shown connection pads 111 , 113 , 115 and 117 are arranged in a row and spaced from each other. The shape of the connection pad 111 , the connection pad 113 , the connection pad 115 and the connection pad 117 is substantially rectangular. The front surfaces of connection pad 111, connection pad 113, connection pad 115 and connection pad 117 (as Figure 1A shown) is used, for example, to form a die-bonding region, and the die-bonding region is used for disposing optoelectronic chips such as LED chips. And the back side of connection pad 111, connection pad 113, connection pad 115 and connection pad 117 (such as Figure 1B shown) is used, for example,...

no. 2 example

[0045] Such as figure 2 As shown, a multi-chip optoelectronic device 20 provided by the second embodiment of the present invention mainly includes: a plurality of optoelectronic chips such as a plurality of LED chips 23 and a surface mount bracket. Wherein, the surface mount bracket is, for example, the surface mount bracket 10 described in the aforementioned first embodiment, and its specific structure and function details can refer to the description of the aforementioned first embodiment, and will not be repeated here. A plurality of LED chips 23 are, for example, disposed in the die-bonding area of the surface mount bracket.

[0046] The size of the surface mount bracket is, for example, 13mm*13mm. A plurality of LED chips 23 includes, for example, fifty-two or twenty-six pairs of LED chips 23. For example, the fifty-two LED chips 23 adopt "26 parallel and 2 strings", that is, two LEDs in each pair of LED chips 23 Chips are connected in series, and then twenty-six pai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com