An experimental analysis method for the study of compressibility of shale samples

An experimental analysis and sample technology, applied in the direction of analyzing materials, using stable tension/pressure to test material strength, strength characteristics, etc., can solve problems that need to be deepened and have not been clarified, whether cracks are formed inside brittle minerals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

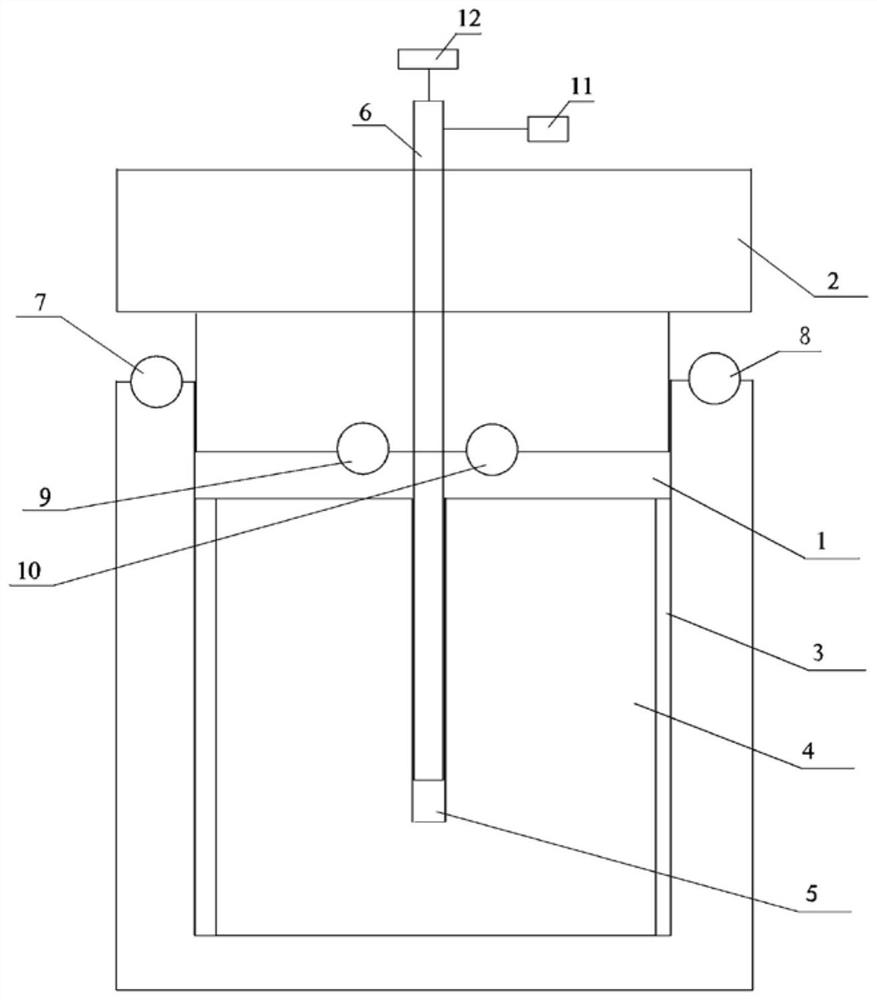

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] Such as figure 1 As shown, it includes a cylindrical autoclave and an autoclave top cover arranged at the opening of the autoclave. The center of the top cover is provided with a through hole for passing the high-pressure pipeline. The high-pressure pipeline can lead into the autoclave cavity. One end of the high-pressure pipeline is provided with a pressure sensor and a fluid booster pumping device. An annular sealing ring is arranged at the through hole of the top cover of the autoclave.

[0029] During the experiment, the shale sample was first processed into a cylindrical plunger 4, and a hole 5 was drilled axially at the center of the plunger 4, and the drilled plunger 4 was placed in a In the sleeve 3 of plunger equal length. The outer edge of the sleeve 3 with the built-in shale sample plunger 4 is coated with a little silicone grease, and then placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com