Pressure intensity mechanical and automatic adjustment viscous damper

A viscous damper and self-adjusting technology, applied in the field of structural shock absorption, can solve the problems of inability to protect the safety of the cylinder block and sealing system, unpredictable internal force redistribution, large differences in calculation models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

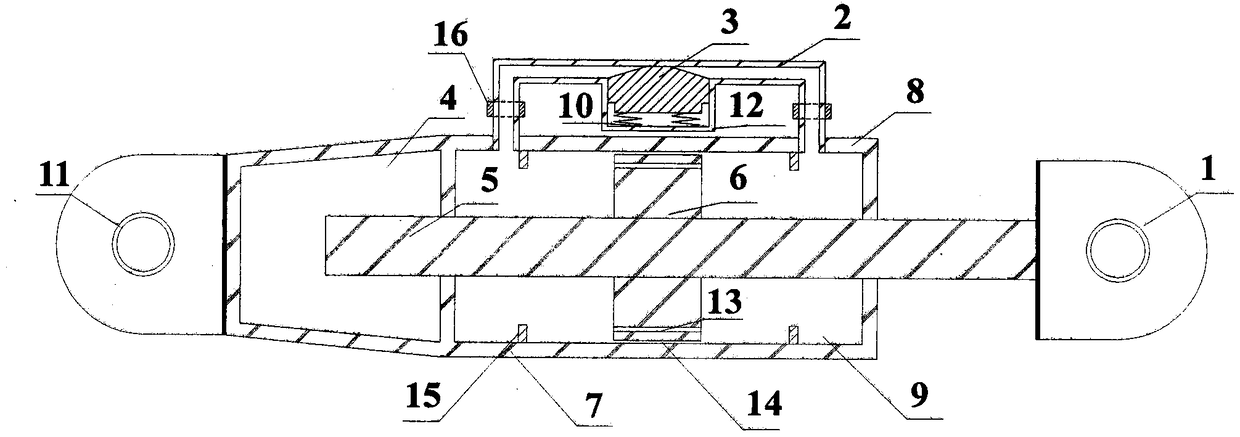

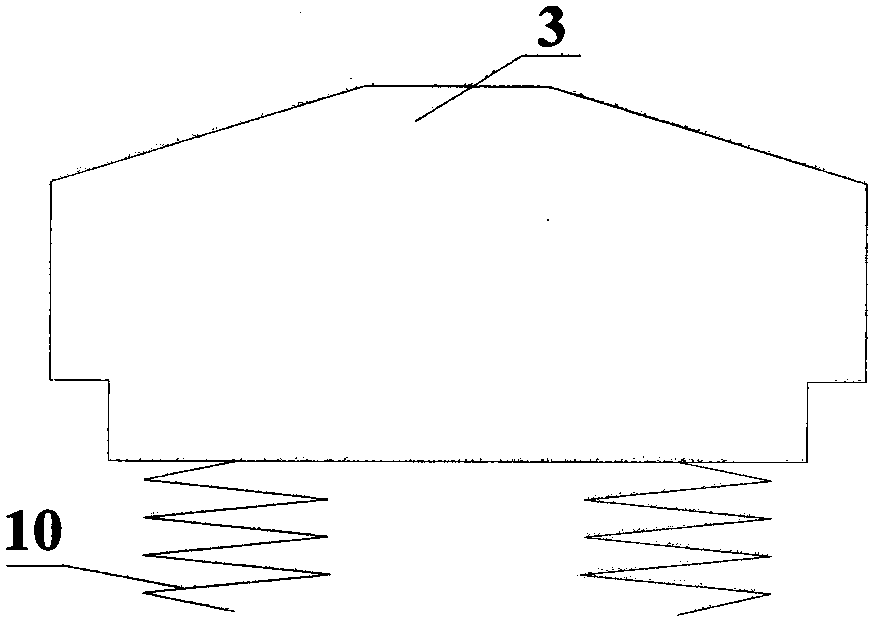

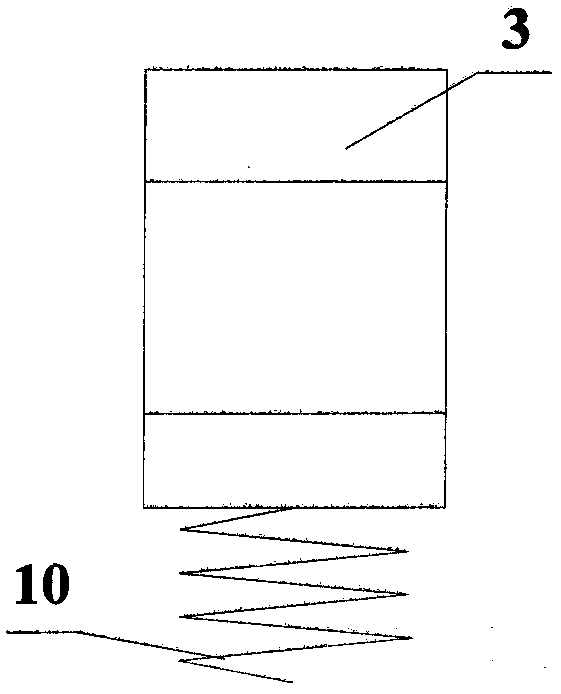

[0016] figure 1 It is a schematic diagram of the overall structure of the self-adjusting pressure type viscous damper according to the present invention. Such as figure 1 As shown, the self-adjusting pressure type viscous damper according to the present invention mainly includes a main cylinder, an auxiliary cylinder 4, a piston 6, a piston rod 5, a liquid pipe 2, a pressure block valve 3, etc., wherein the main cylinder is divided into a left main cylinder Cylinder 7 and right master cylinder 8, left master cylinder 7 and right master cylinder 8 are filled with identical damping medium 9. The piston 6 is arranged between the left master cylinder 7 and the right master cylinder 8 and can move back and forth along its axial direction, thereby dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com