Constructing method of through steel box arch bridge

It is a construction method and the technology of underlayment, which is applied in the direction of arch bridge, bridge, bridge construction, etc., and can solve the problems of difficult design and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below with reference to the accompanying drawings.

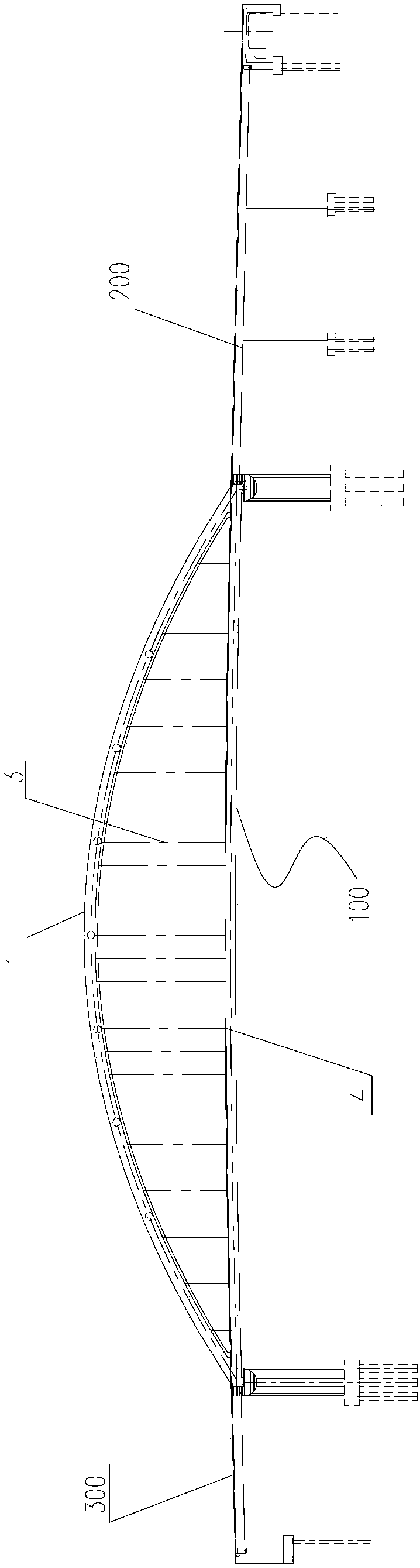

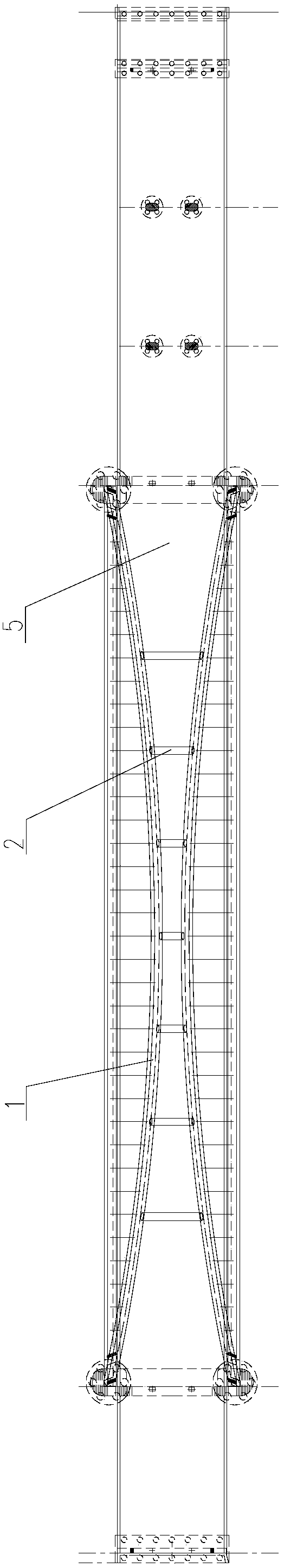

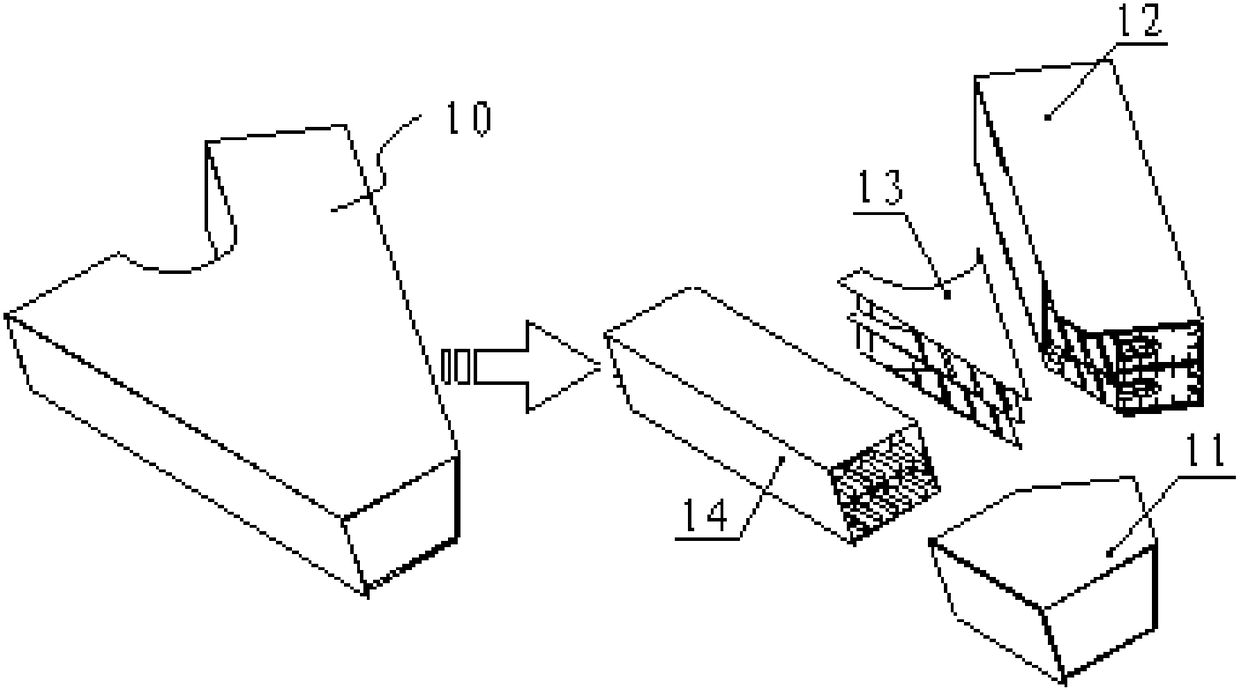

[0082] see Figure 1 to Figure 10 , the present invention is a construction method of the main bridge of the under-type steel box arch bridge, the under-type steel box arch bridge includes the south bank approach bridge 200, the north bank approach bridge 300 and the main bridge 100. The main bridge 100 includes an arch rib 1, a hanger 3, a main beam 4 and an orthotropic bridge deck 5; the arch rib 1 has two upstream and downstream, and the middle is connected by 7 permanent transverse braces 2, and the single arch 1 is divided into 37 Each section includes arch feet 10 at both ends; the main beam 4 includes longitudinal beams and beams and is divided into 37 sections along the longitudinal direction of the bridge deck; the beam includes two end beams 40 and several general beams, and the two end beams 40 are arranged respectively At the arch foot on the north bank side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com