Steel rail tread sander

A grinding machine and rail technology, which is applied to track, track laying, track maintenance, etc., can solve problems such as engine flameout, achieve the effects of reducing idling, avoiding flameout, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

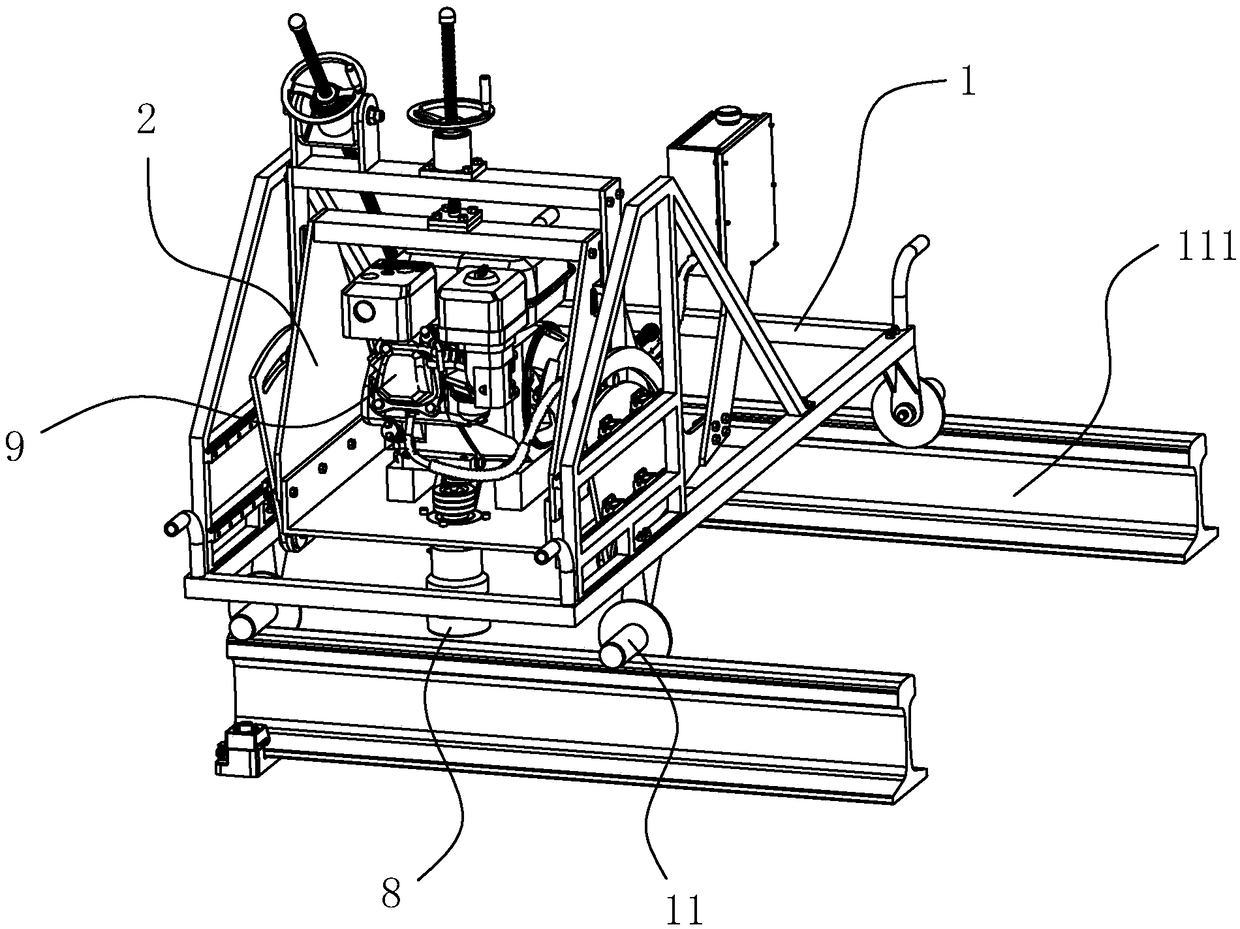

[0038] A kind of rail tread grinding machine, with reference to figure 1 , which includes a frame 1, a grinding part adjustment mechanism 2, a grinding part 8 and an engine 9; both ends of the frame 1 are provided with traveling wheels 11, so that the frame 1 moves along the length direction of the rail 111 on the rail 111; the grinding The parts adjusting mechanism 2 is arranged on the frame 1, and the grinding parts 8 and the engine 9 are arranged on the grinding parts adjusting mechanism 2.

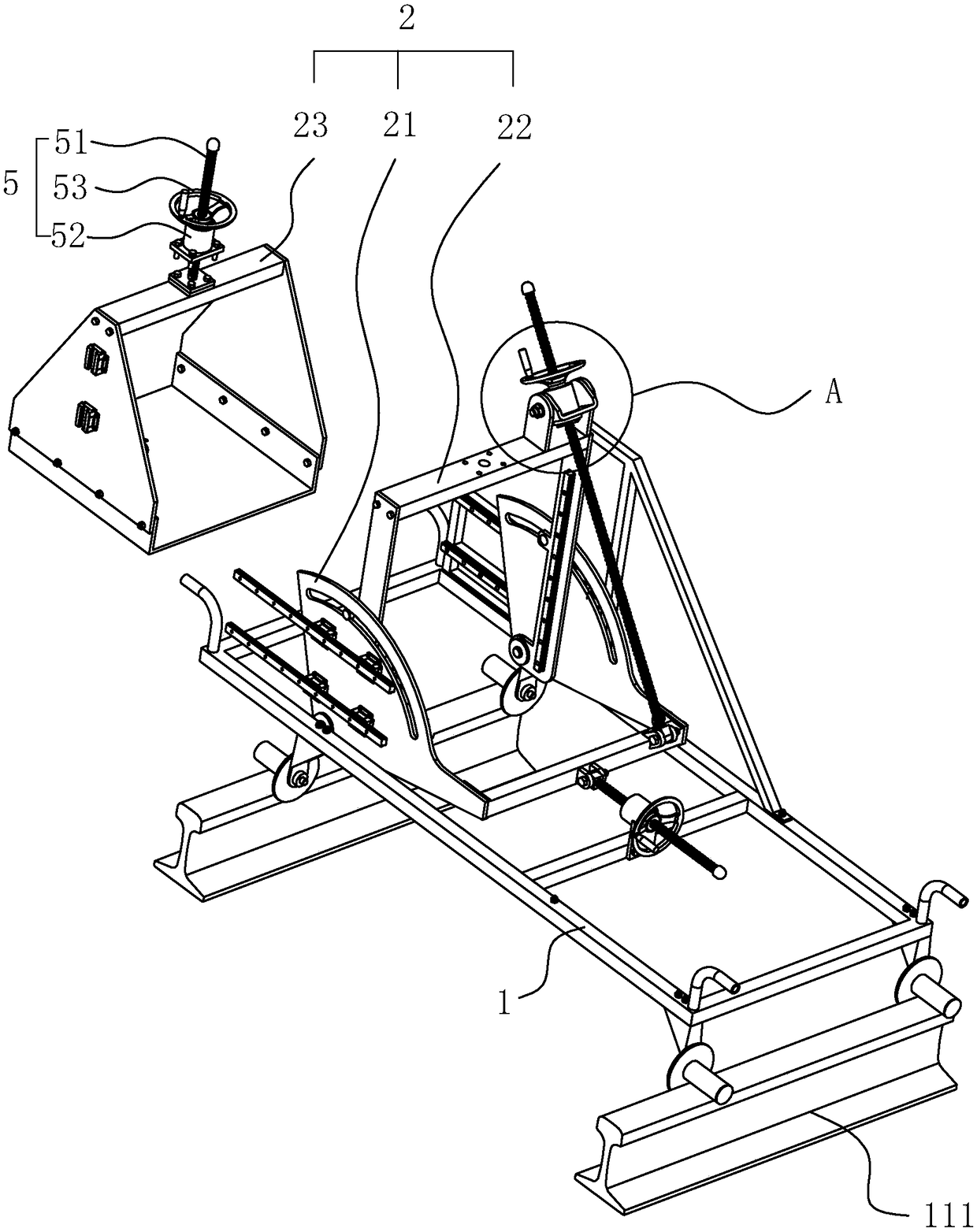

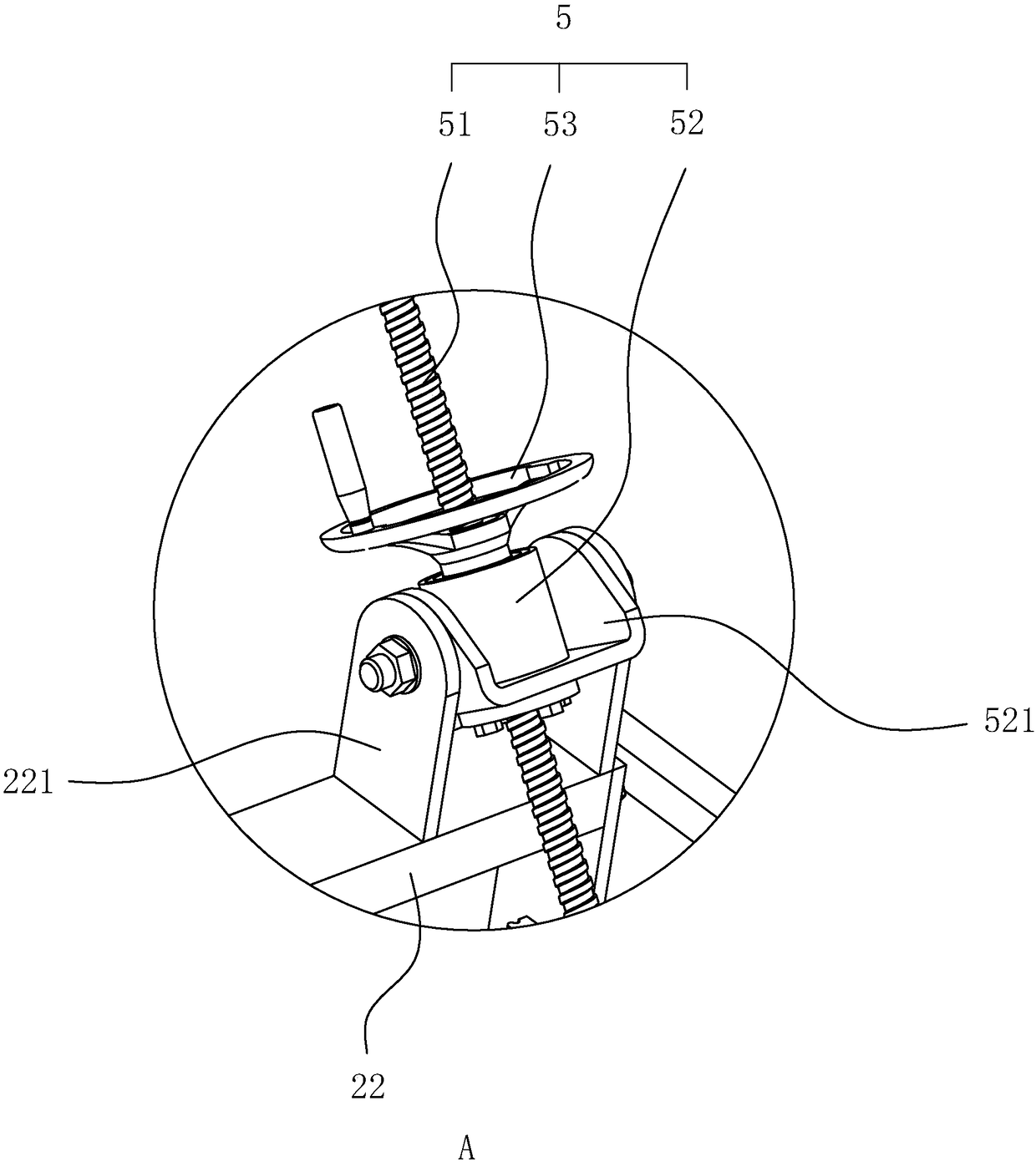

[0039] refer to figure 2 , the grinding part adjustment mechanism 2 includes a horizontal support 21, an angle support 22 and a height support 23; the horizontal support 21 is connected with the frame 1 along the width direction of the rail 111 through guide rail sliding; the angle support 22 and the horizontal support 21 rotate along the width direction of the steel rail 111 Connected, the lower end of the angle bracket 22 is rotationally connected with the horizontal bracket 21 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com