Reinforced phase regulation and control method for TiB reinforcing titanium-based composite

A titanium-based composite material and a technology for composite materials, applied in the field of metal-based composite materials, can solve problems such as reinforcement phase regulation, and achieve the effects of improving mechanical properties, broadening the scope of preparation and application, and strong process applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

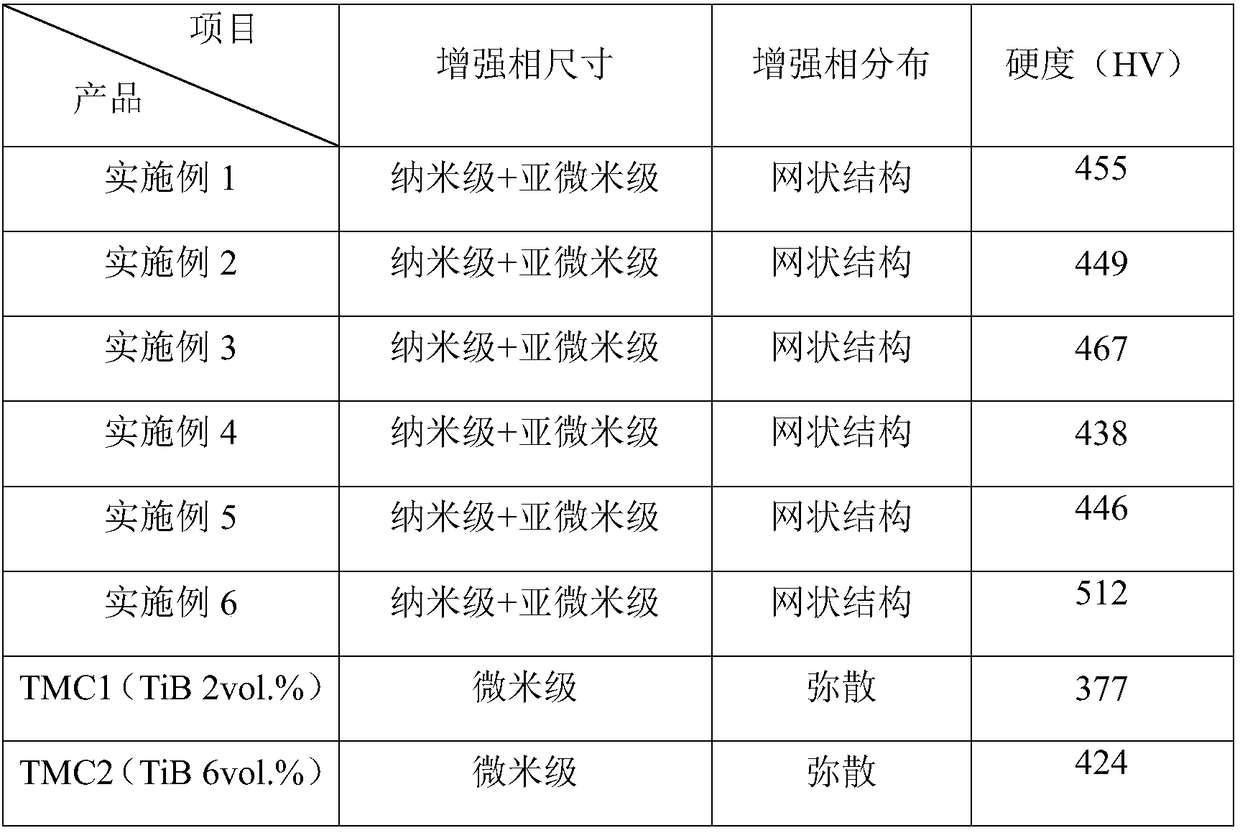

Embodiment 1

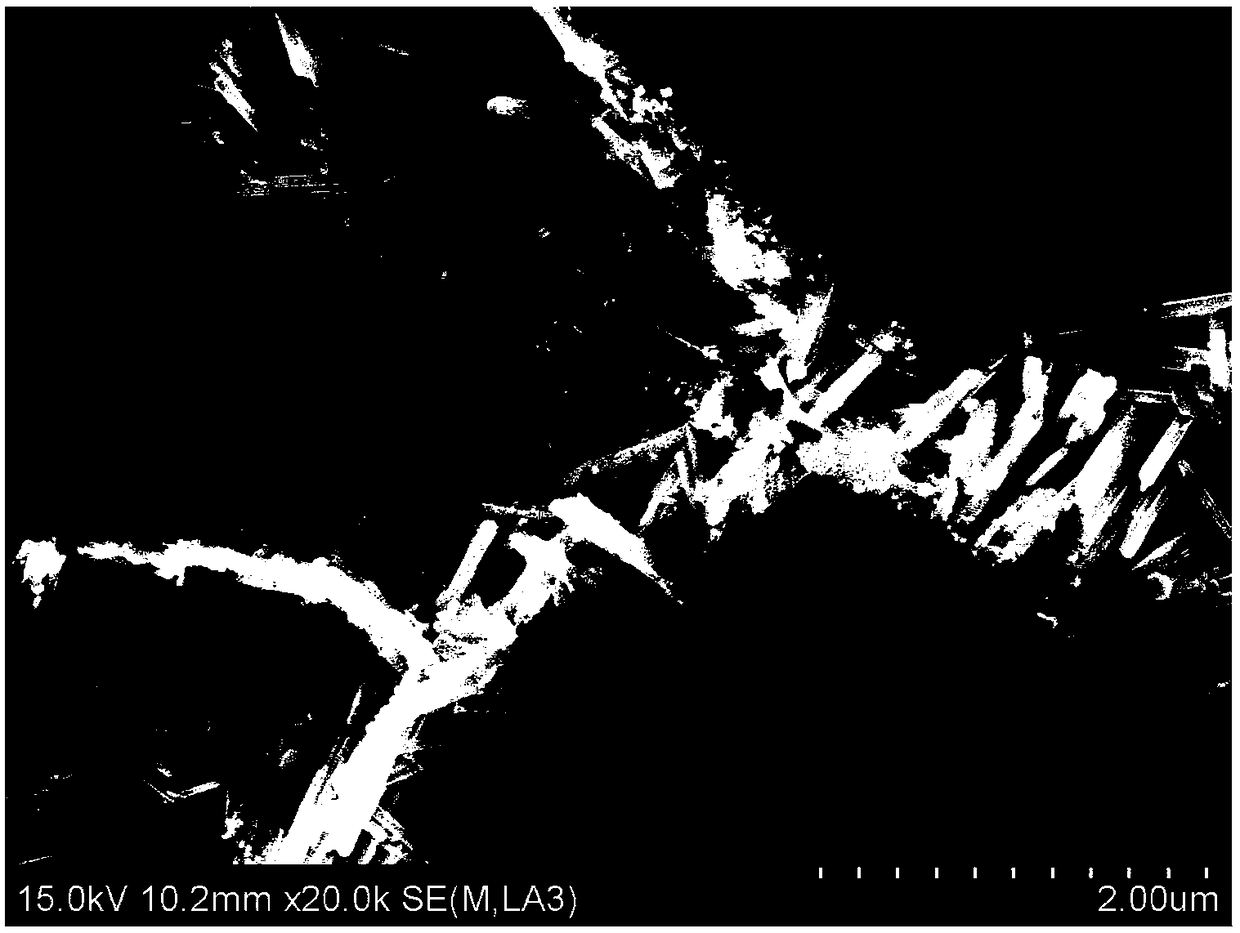

[0021] Using TiB (2vol.%) reinforced titanium-based composite material as the matrix, the TiB-reinforced titanium-based composite material is firstly melted by electron beam technology, in which the current is 9mA, the voltage is 40kV, the scanning speed is 10mm / s, and the heat output is 3.6J / mm . Then, low-temperature aging treatment is carried out on the melted composite material, wherein the aging temperature is 500°C, the holding time is 8h, and it is cooled with the furnace.

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 lies in the electron beam melting treatment, in which the current is 6 mA, the voltage is 60 kV, the scanning speed is 10 mm / s, and the heat output is 3.6 J / mm.

Embodiment 3

[0025] The difference between this embodiment and Embodiment 1 lies in the electron beam melting treatment, wherein the current is 6 mA, the voltage is 50 kV, the scanning speed is 10 mm / s, and the heat output is 3 J / mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com