Logistics automatic sorting remote diagnosis system and method thereof

An automatic sorting and remote diagnosis technology, which is applied to conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problems of ignorance of on-site personnel, low efficiency, affecting on-site operations, etc., to prevent the reduction of operating rate. , The effect of ensuring operating efficiency and shortening fault repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific drawings and embodiments.

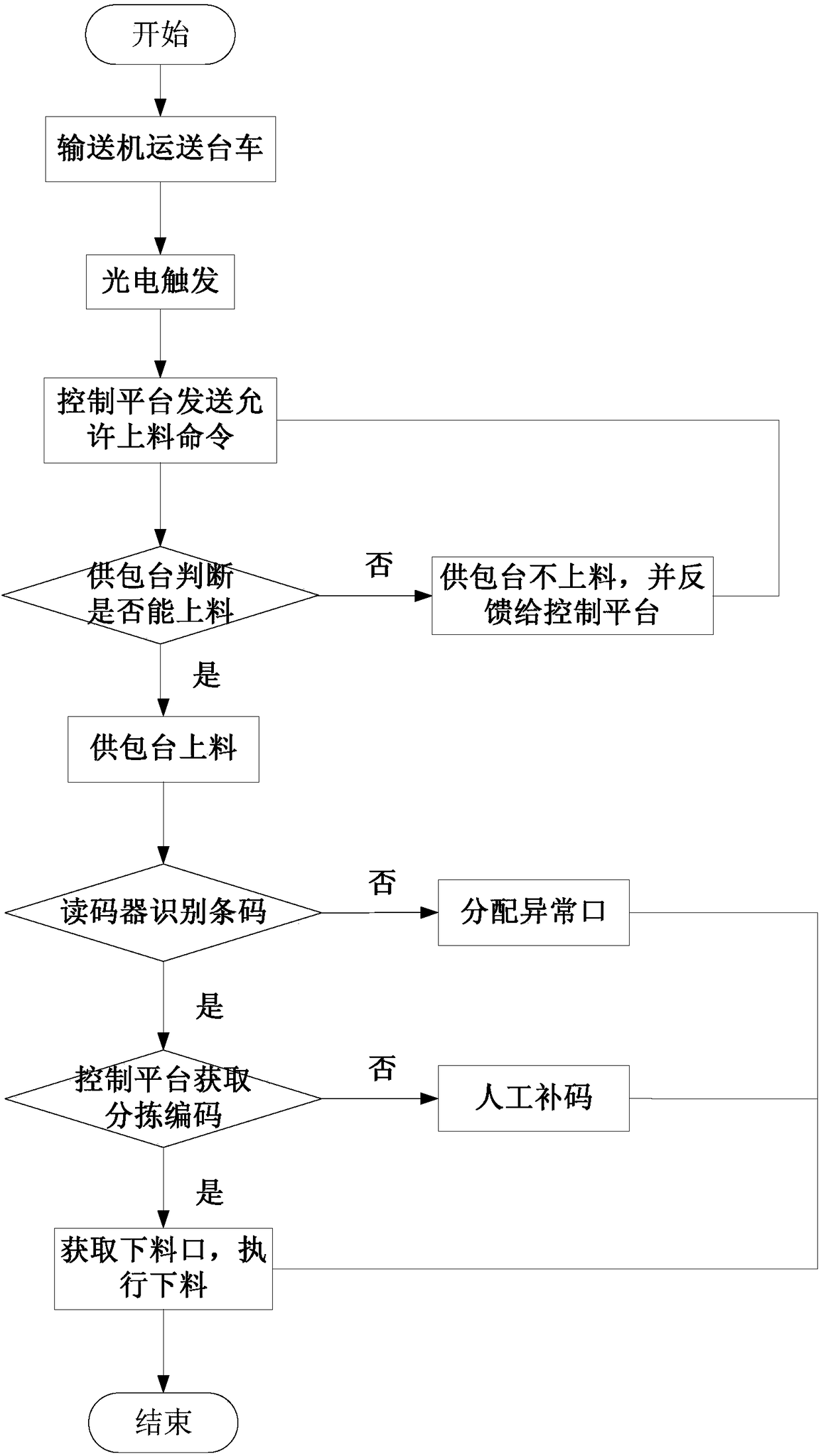

[0041] Such as figure 1 with figure 2 As shown, a logistics automatic sorting remote diagnosis system includes a sorting line for sorting parcels, and the sorting line includes several belt conveyors 5 for transporting trolleys 4, and the belt conveyor 5 The main function is to provide a carrying and running platform for the small trolley 4 on the track. Each trolley 4 is an independent unit, which is used to transport the package to the designated discharge port 12. When loading, the belt needs to be rotated. Place the parcel at the central position of the trolley 4, turn the belt when unloading, and unload the parcel from the trolley 4. It is characterized in that: the sorting line also includes a photoelectric baffle 11 located on the track of the feeding port, A number of bag supply platforms 2 for feeding, several feeding ports 12 located at the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com