Spindle structure on precision grinder

A precision grinding machine and spindle technology, applied in the mechanical field, can solve the problem that the grinding effect of the dynamic and static pressure spindle cannot meet the requirements of the roll grinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

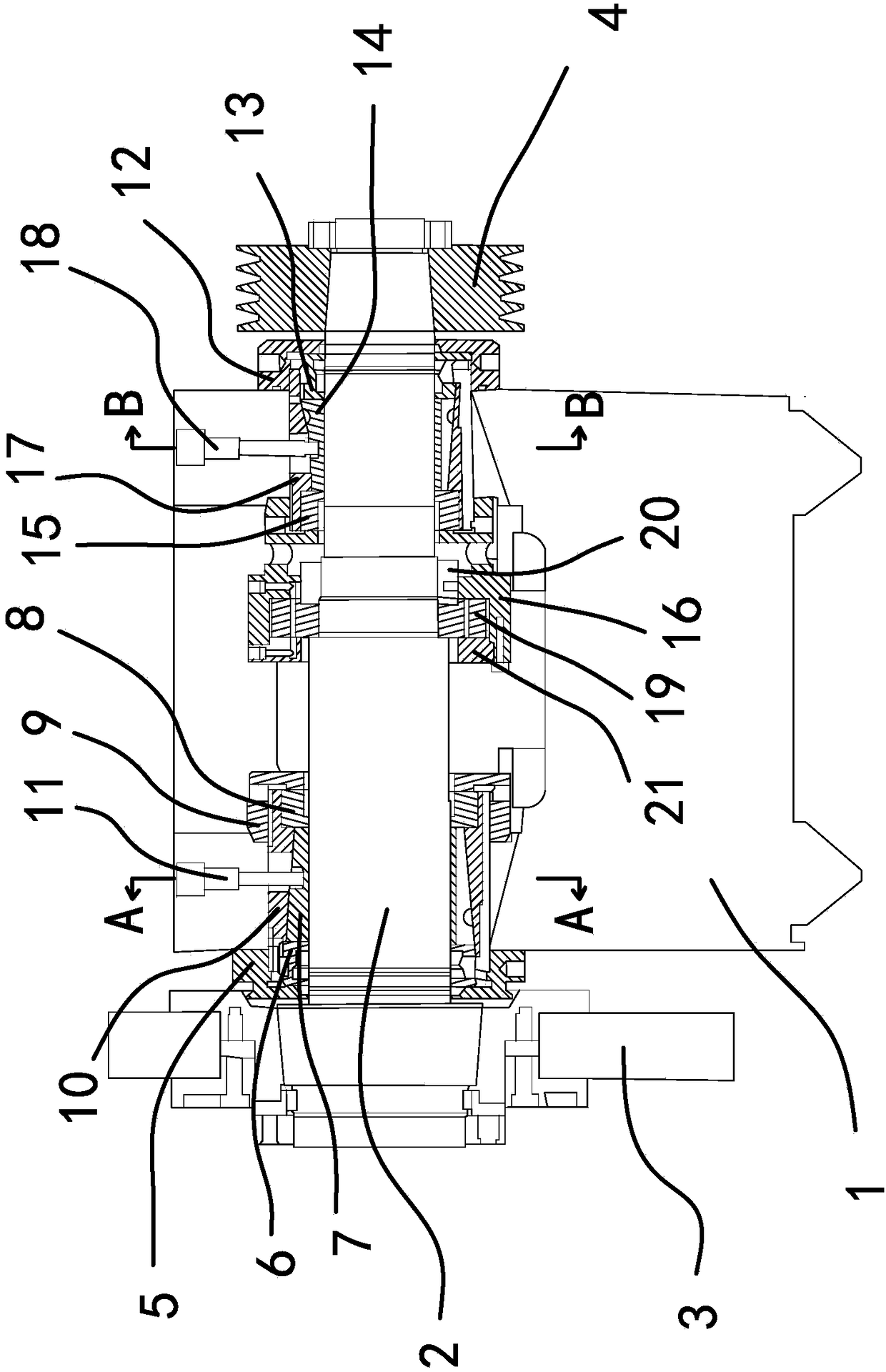

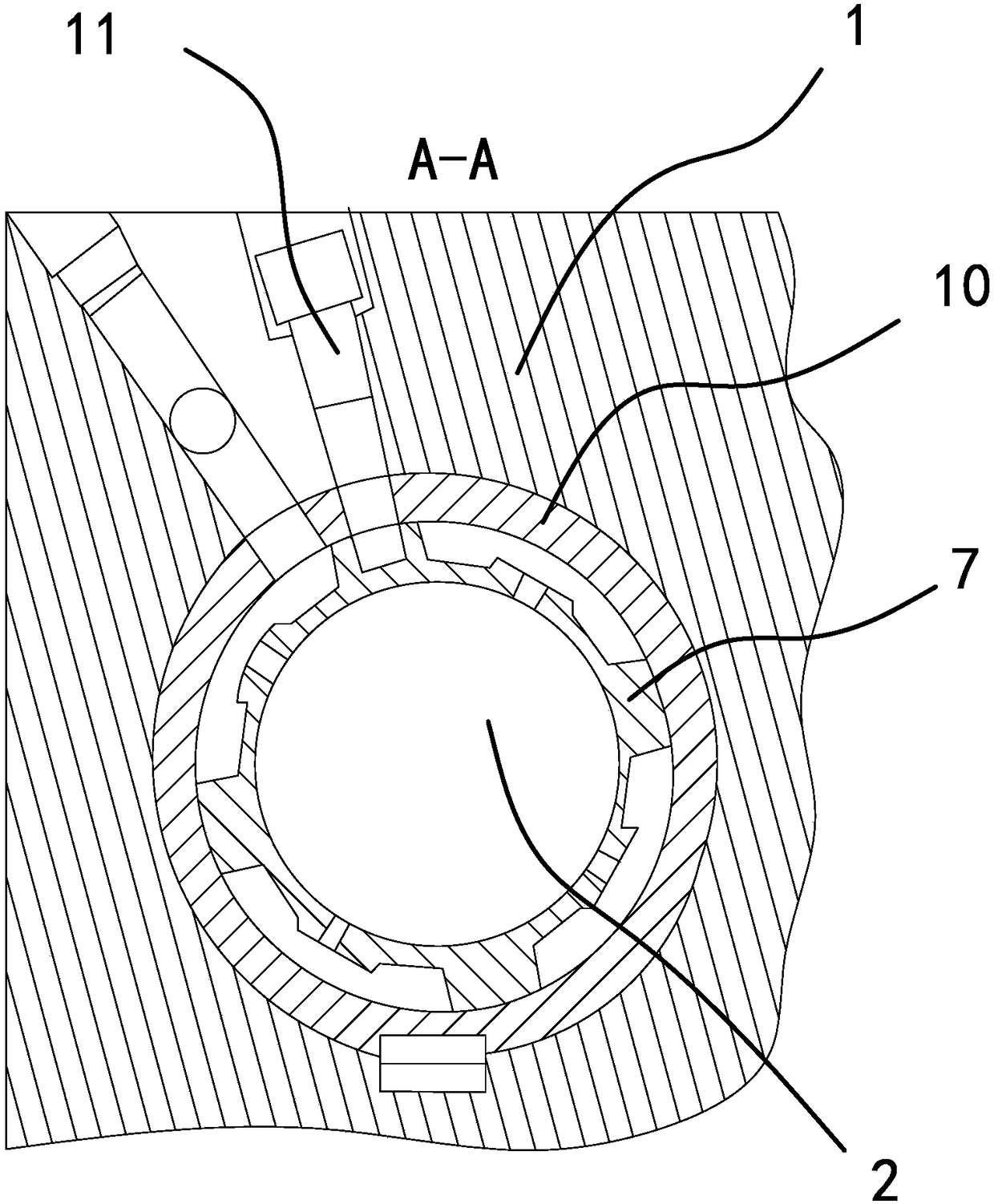

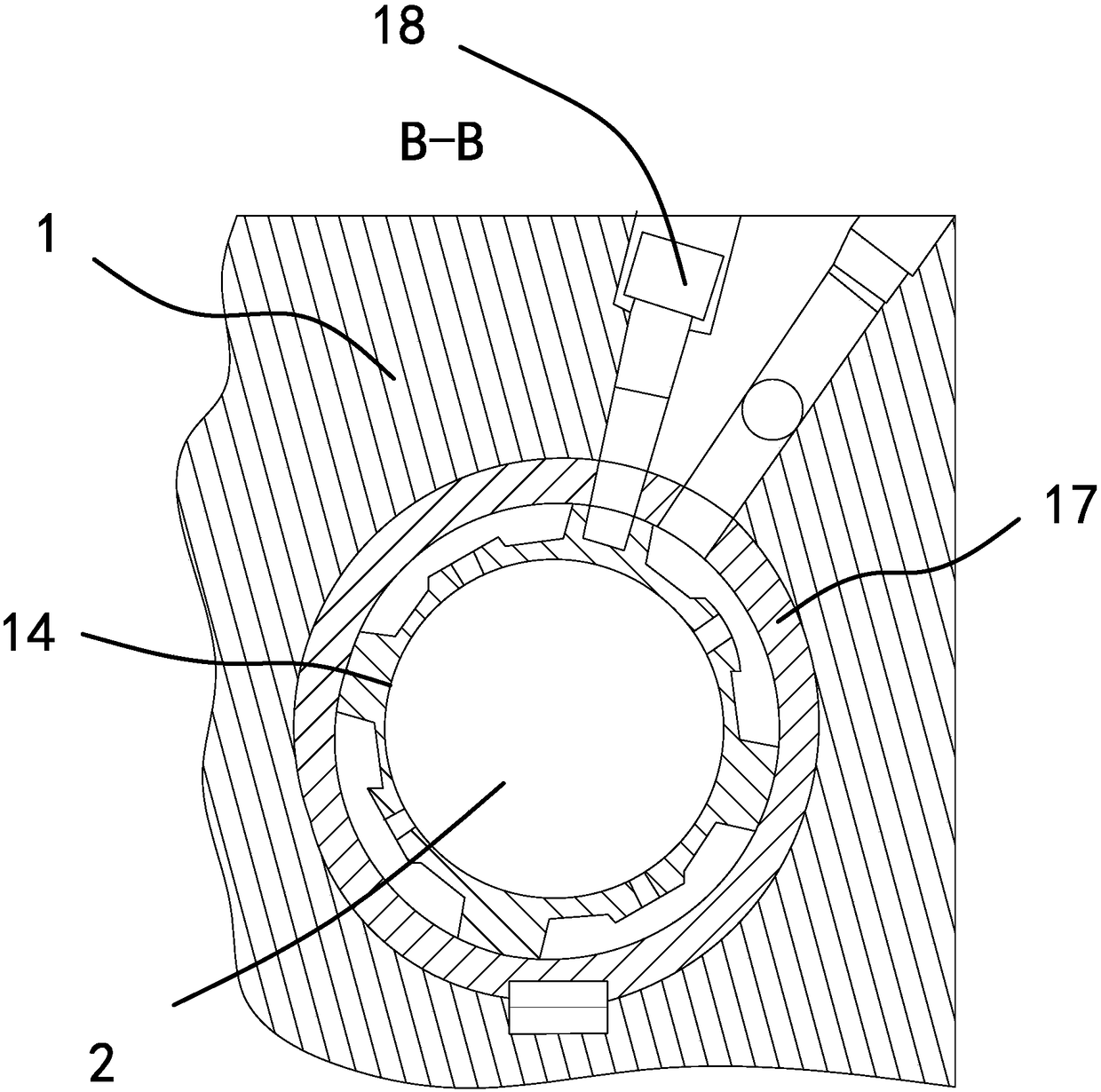

[0012] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0013] Such as Figure 1 to Figure 3 As shown, the main shaft structure of the precision grinder is set on the grinding wheel frame 1, including the main shaft 2. The left end of the main shaft 2 is connected with a grinding wheel 3, the right end of the main shaft 2 is connected with a pulley 44, and the left end of the main shaft 2 is installed from left to right. The main lock nut 5, the left main retaining ring 6, the left bearing bush 7 with an outer cone, the left auxiliary retaining ring 8 and the left auxiliary lock nut 9, the two ends of the left bearing 7 abut on the left main retaining ring 6 and the left Between the auxiliary retaining rings 8, the left main lock nut 5 and the left auxiliary lock nut 9 are threadedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com