Novel sealing element

A new type of seal, applied in the field of industrial parts, can solve the problems of small deformation of the annular rubber ring, easy radial rotation, poor sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

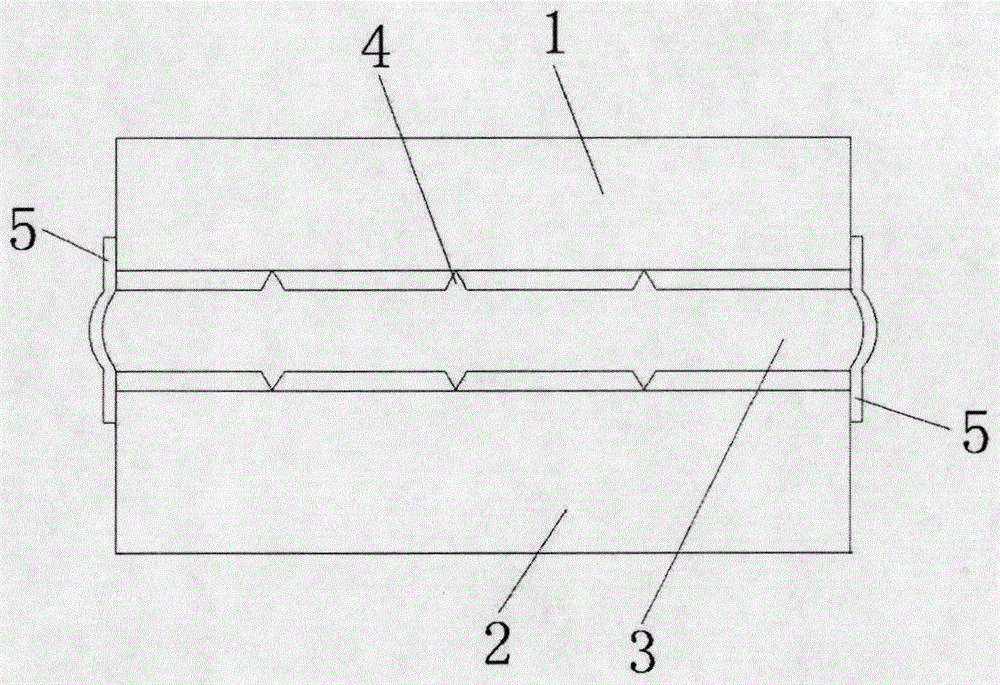

[0011] Such as figure 1 Shown: a new type of seal, including a first shell 1 and a second shell 2, the first shell 1 and the second shell 2 are provided with an annular sealing body 3, the annular sealing body 3 Both the upper and lower surfaces are provided with at least three convex ribs 4 integrally formed with the annular sealing body, the cross section of the convex ribs 4 is triangular or trapezoidal, and the edges of the upper and lower surfaces of the annular sealing body 3 are provided with annular covers 5, The annular sealing body 3 may also be provided with at least three ribs 4 integrally formed with the annular sealing body 3 on the upper or lower surface, and an annular cover 5 is provided on the edge of the upper or lower surface of the annular sealing body 3. By arranging the convex ribs 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com