Coiling cooling control device and coiling cooling control method

A technology of cooling control and cooling device, applied in workpiece cooling device, temperature control, metal rolling, etc., can solve problems such as the reduction of steel plate quality, and achieve the effect of improving manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the respective drawings, the same reference numerals are given to the common structural members, and repeated descriptions thereof are omitted.

[0031]

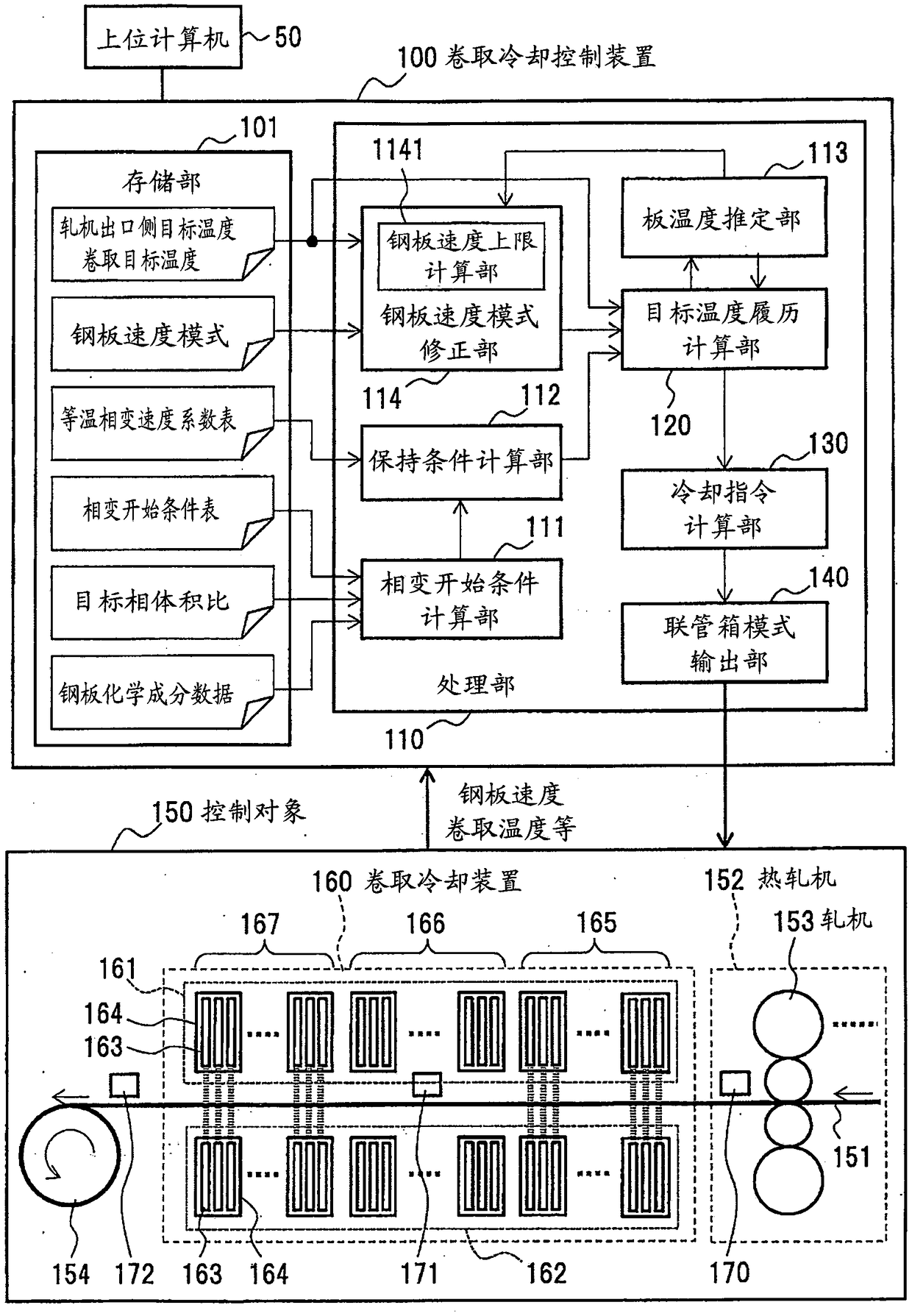

[0032] figure 1 It is a figure which shows the example of the structure of the winding cooling control apparatus 100 and its control object 150 in embodiment of this invention. Such as figure 1 As shown, the coiling cooling control device 100 receives various signals (the actual values of the steel plate speed, the coiling temperature, etc.) from the control object 150, and outputs the control signal corresponding to the actual value to the control object 150.

[0033] Here, first, the structure of the control target 150 will be described. In the case of this embodiment, the main structural component of the control target 150 is the coiling cooling device 160 in the hot rolling system. The coili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com