Automobile part paint spraying assembly line

A technology for auto parts and assembly lines, applied in spray booths, spray devices, pre-treated surfaces, etc., can solve problems affecting the dimensional accuracy of parts, affecting the use of parts, and difficult to guarantee the quality of painting, so as to ensure uniformity, improve accuracy, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

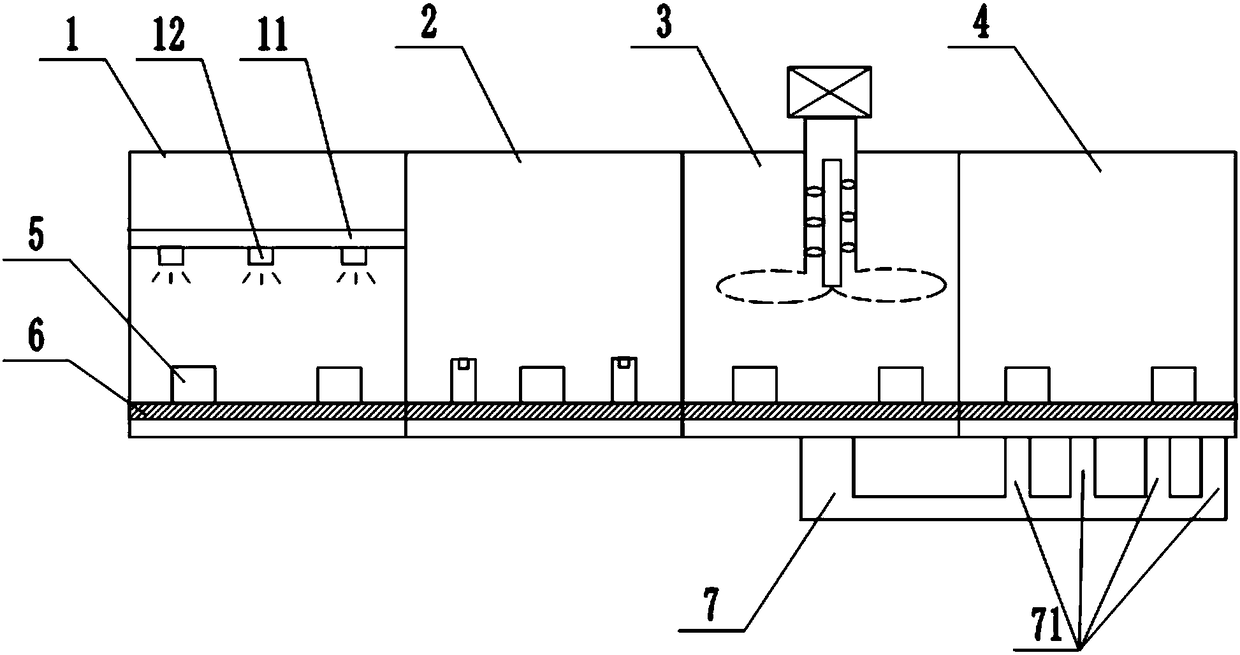

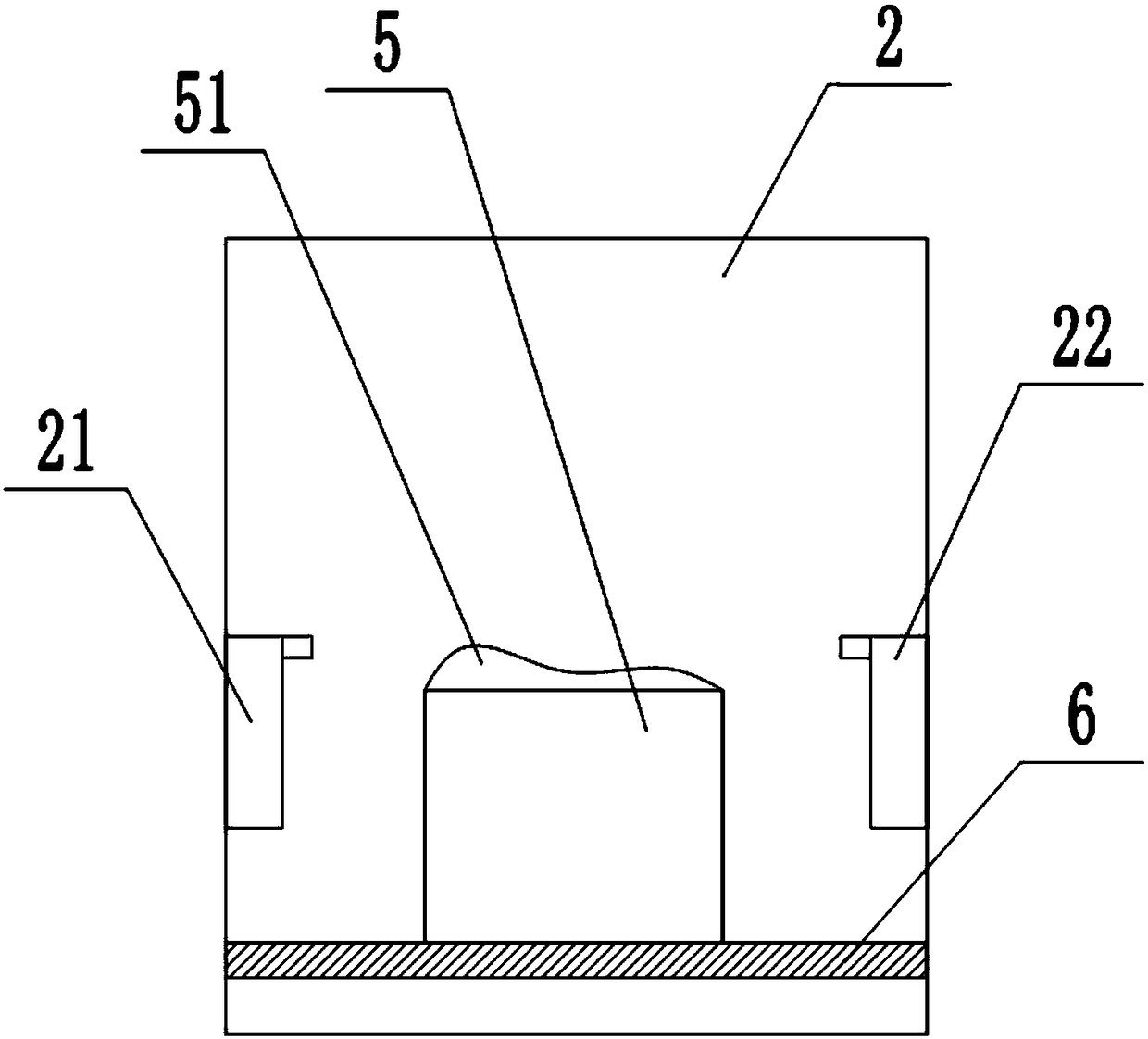

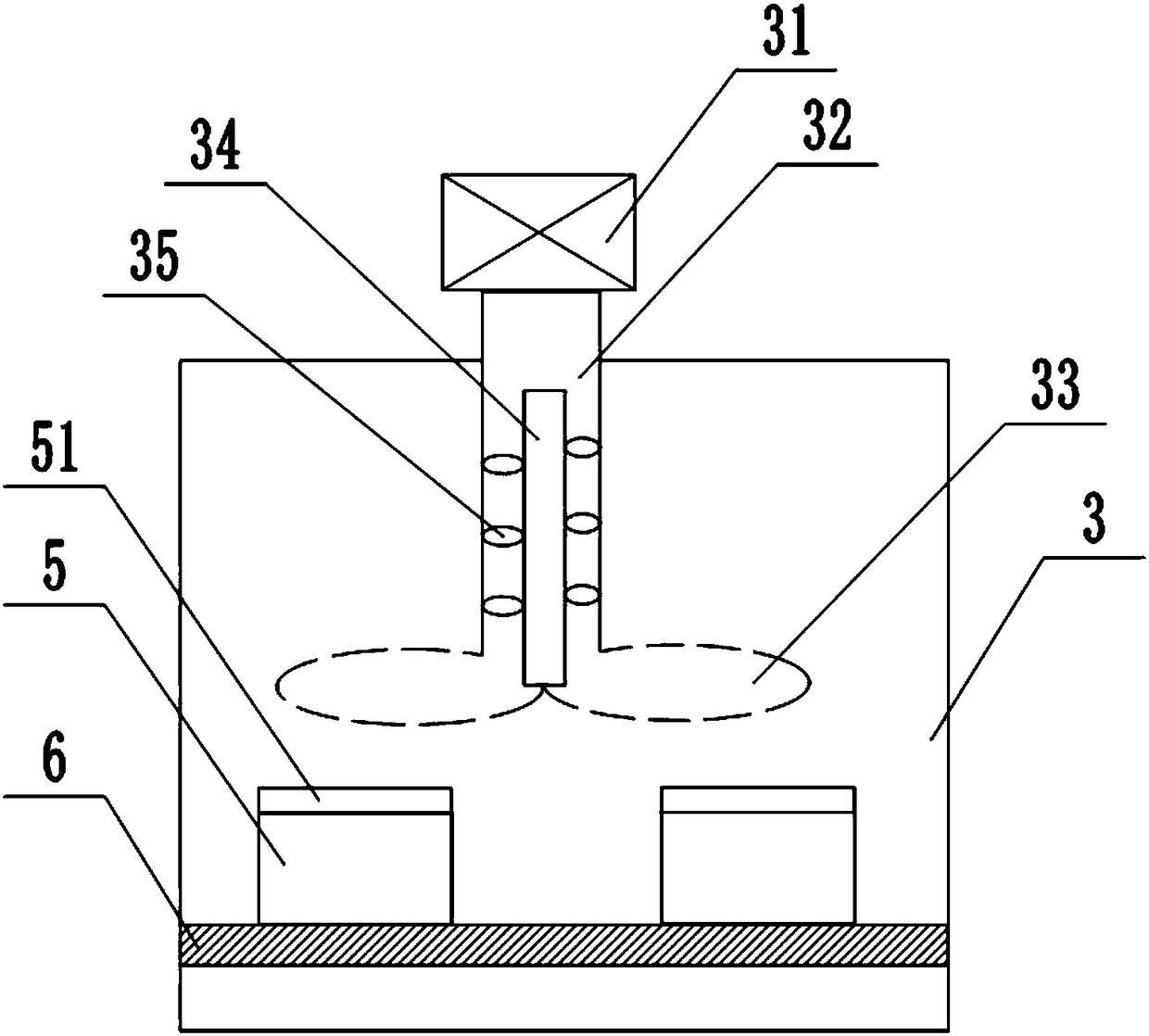

[0021] The reference numerals in the accompanying drawings of the specification include: a paint spray booth 1, a support 11, a paint spray gun 12, a detection chamber 2, an infrared emitter 21, an infrared receiver 22, a controller 23, a processor 24, a second conveyor belt 25, a pre-baking Dry chamber 3, fan 31, hollow rod 32, fan blade 33, rotating rod 34, spiral blade 35, drying chamber 4, parts 5, paint 51, first conveyor belt 6, exhaust pipe 7, branch pipe 71.

[0022] The embodiment is basically as attached Figures 1 to 4 Shown: a painting assembly line for auto parts, the assembly line includes a paint spraying room 1, a testing room 2, a pre-drying room 3 and a drying room 4 connected in sequence, a painting room 1, a testing room 2, a pre-drying room 3 and a drying room The first conveyor belts 6 for conveying the parts 5 to be processed are respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com