Greenhouse heat collecting and releasing intelligent control device and efficient control method

A technology of intelligent control and greenhouse collection, which is applied in the fields of greenhouse cultivation, botanical equipment and methods, climate change adaptation, etc., can solve the problems of loss of system heat, ineffective operation and energy consumption, weak solar radiation, etc., and achieve high system heat collection efficiency. , Avoid operation and energy consumption, the effect of large system heat collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

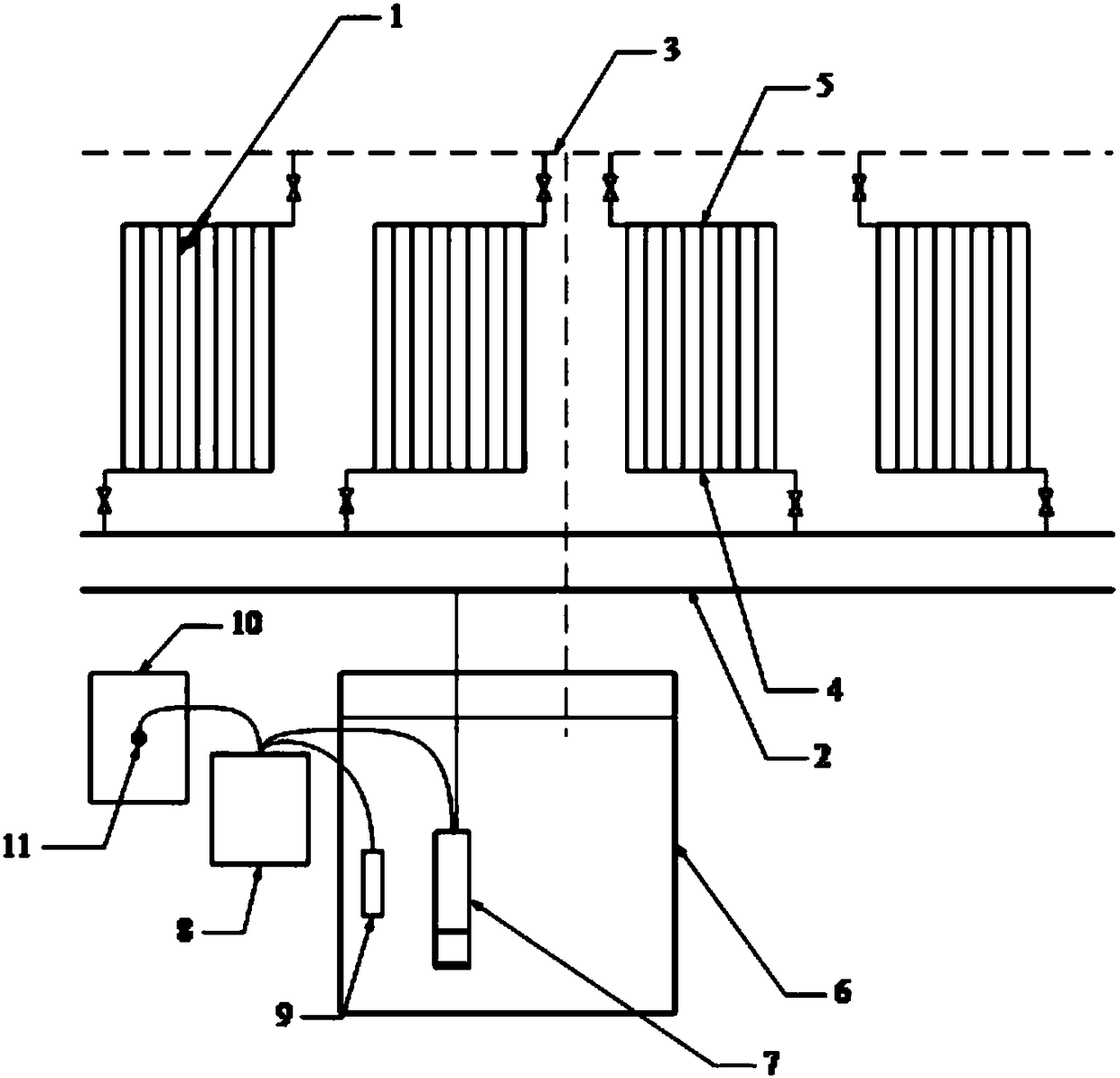

Method used

Image

Examples

Embodiment 1

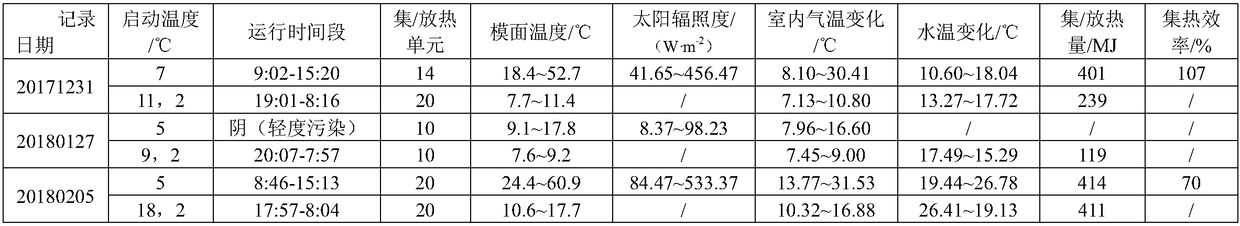

[0025] This embodiment is carried out in the solar greenhouse of Beijing International Urban Agricultural Science and Technology Park in Lucheng Town, Tongzhou District, Beijing. The length of the greenhouse is 50m from east to west, the span from north to south is 8m, the height of the ridge is 3.8m, and the height of the back wall is 2.6m. A rear wall water circulation solar heat collection and release system is installed on the inner surface of the back wall of the greenhouse. There are 20 heat collection and release units in total. The height of each heat collection and release unit is 2.11m, and the width is 2m. The total effective heat collection and release area is 84.4m 2 . On December 31, 2017, 14 heat collecting units were operated during the day and 20 heat collecting units were operated at night. Specifically include:

[0026] (1) The heat collection process during the day,

[0027] 1) Set the start-up condition of the heat collection system: in the automatic co...

Embodiment 2

[0037] This embodiment is still carried out in the solar greenhouse of Beijing International Urban Agricultural Science and Technology Park in Lucheng Town, Tongzhou District, Beijing. The time is January 27, 2018, with 10 heat collecting units running during the day and 10 heat collecting units running at night. Specifically include:

[0038] (1) Daytime heat collection process

[0039] 1) Setting the start-up condition of the heat collection system: In the automatic control system 8, set the difference between a mold surface temperature and the water temperature of 5°C as the start-up condition.

[0040] 2) Heat collection situation: It was cloudy and slightly polluted during the day, which failed to meet the heat collection operation conditions of the system. Therefore, the system failed to collect heat during the day.

[0041] (2) Heat release process at night

[0042] 1) Setting the start-up conditions of the exothermic system: In the automatic control system 8, set a ...

Embodiment 3

[0047] The present embodiment is carried out in the solar greenhouse of the Beijing International Urban Agricultural Science and Technology Park in Lucheng Town, Tongzhou District, Beijing, as in the first embodiment. The time is February 5, 2018, 20 heat collecting units are operated during the day, and 20 heat collecting units are operated at night. Specifically include:

[0048] (1) Daytime heat collection process

[0049] 1) Setting the start-up condition of the heat collection system: In the automatic control system 8, set the difference between a mold surface temperature and the water temperature of 5°C as the start-up condition.

[0050] 2) Heat collection start: During the day, after the solar greenhouse is uncovered, the solar radiation is enhanced, and the indoor temperature rises. When the automatic control system 8 monitors through the water temperature sensor 9 and the mold surface temperature sensor 11 that the set heat collection starting condition is reached,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com