Method for treating salinized grassland by using yellow corn silage straws

A salinization and straw technology, applied in land preparation methods, chemical instruments and methods, applications, etc., can solve the problems of poor improvement effect and immature comprehensive technology, so as to increase soil nutrients, prevent soil water evaporation, and yellow storage methods. Simple and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

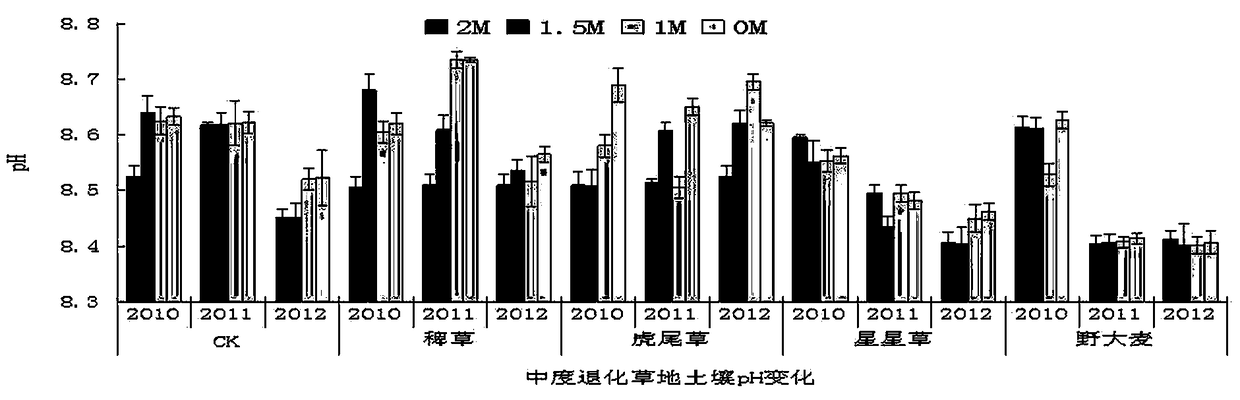

Image

Examples

Embodiment 1

[0072] A method for treating saline-alkali grassland with yellow stalks, comprising the following steps:

[0073] Step 1: Production of Yellow Storage Straw:

[0074] Harvesting: The production of yellow stalks is completed after harvesting corn ears, and it is completed within one month after harvesting;

[0075] Chopping: Cut the harvested straw raw materials to short length, the length of the straw is 1-2cm;

[0076] Cellar loading: After cutting the raw materials, add water to make the water content reach 40-50%, and fill them into yellow storage cellars in layers;

[0077] Compaction: Each layer is compacted, the thickness of each layer is controlled below 20cm, and the air is removed as much as possible. The filling process can be completed in three days;

[0078] Sealing: Fill the raw materials to 40-50cm higher than the cellar mouth, and seal the cellar when the middle of the cellar top is high and the surrounding area is low. After sealing, cover the top with a laye...

Embodiment 2

[0085] A method for treating saline-alkali grassland with yellow stalks, comprising the following steps:

[0086] Step 1: Production of Yellow Storage Straw:

[0087] Harvesting: The production of yellow stalks is completed after harvesting corn ears, and it is completed within one month after harvesting;

[0088] Chopping: cutting the harvested stalks short, the length of the stalks is 2cm;

[0089] Cellar loading: After cutting the raw materials, add water to make the water content reach 50%, and fill them into yellow storage cellars in layers;

[0090] Compaction: Each layer is compacted, the thickness of each layer is controlled below 20cm, and the air is removed as much as possible. The filling process can be completed in three days;

[0091] Sealing: the raw materials are filled to 50cm above the cellar mouth, and the cellar is sealed when the middle of the cellar top is high and the surrounding area is low. After sealing, cover the top with a layer of plastic film, an...

Embodiment 3

[0098] A method for treating saline-alkali grassland with yellow stalks, comprising the following steps:

[0099] Step 1: Production of Yellow Storage Straw:

[0100] Harvesting: The production of yellow stalks is completed after harvesting corn ears, and it is completed within one month after harvesting;

[0101] Chopping: cutting the harvested stalks short, the length of the stalks is 1cm;

[0102] Cellar loading: add water to the raw materials after cutting to make the water content reach 40%, and fill them into yellow storage cellars in layers;

[0103] Compaction: Each layer is compacted, the thickness of each layer is controlled below 20cm, and the air is removed as much as possible. The filling process can be completed in three days;

[0104] Sealing: the raw material is filled to 40cm above the cellar mouth, and the cellar is sealed when the middle of the cellar top is high and the periphery is low. After sealing, a layer of plastic film is covered on the top, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com