Nanocellulose graphene oxide electrothermal material and preparation method thereof

A technology of nanocellulose and electrothermal materials, applied in heating element materials, electrothermal devices, ohmic resistance heating, etc., can solve the problems of unfavorable working process stability, low degree of graphene dispersion, and inconspicuous space network skeleton structure, etc. Achieve the effect of improving density and moisture resistance stability, and enhancing work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step 1. Select the substrate. After the substrate is dried by brushing the surfactant, spray paint on the surface of the substrate to form the first insulating layer. The coating amount is 100g / m 2 , and dried in a vacuum oven at 80°C for 5 hours.

[0052] Step 2: Adhere the copper foil to the insulating coating of the base to make electrodes; the distance and arrangement direction between the two electrodes are determined according to the effective heating area and the profile of the base.

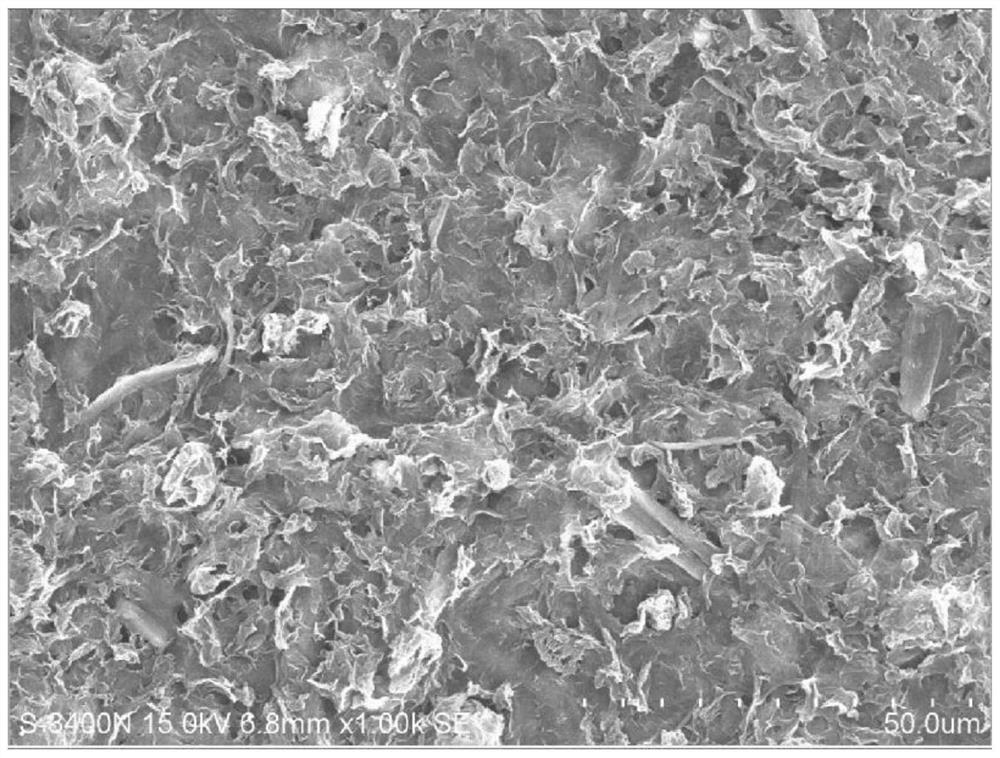

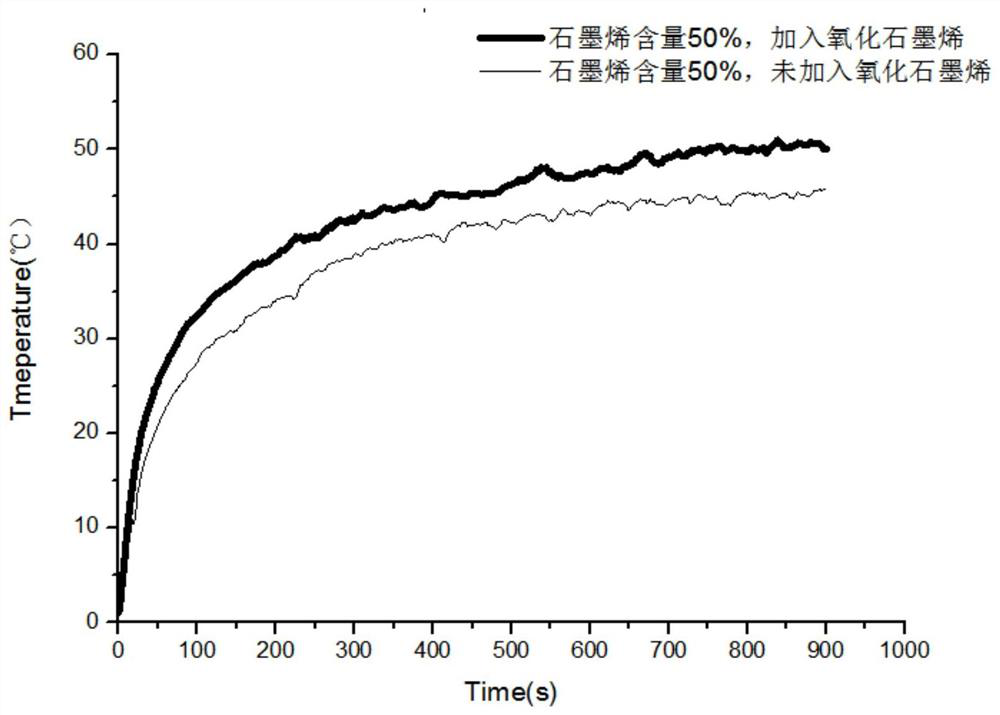

[0053] Step 3: Weigh graphene, graphene oxide, and nanocellulose with a mass ratio of 0.5:0.25:0.25, i.e. graphene 5g, graphene oxide 2.5g, and nanocellulose 2.5g. The cellulose was mixed to form an aqueous dispersion with a concentration of 0.5 mg / ml, and the mixed system was obtained after ultrasonic dispersion at 800W power for 50 min.

[0054] Step 4, using the weighed graphene to prepare a graphene aqueous dispersion with a concentration of 0.5 mg / ml, and ultrasonically dispe...

Embodiment 2

[0061] Step 1. Select the substrate. After the substrate is dried by brushing the surfactant, spray paint on the surface of the substrate to form the first insulating layer. The coating amount is 100g / m 2 , and dried in a vacuum oven at 80°C for 5 hours.

[0062] Step 2: Adhere the copper foil to the insulating coating of the base to make electrodes; the distance and arrangement direction between the two electrodes are determined according to the effective heating area and the profile of the base.

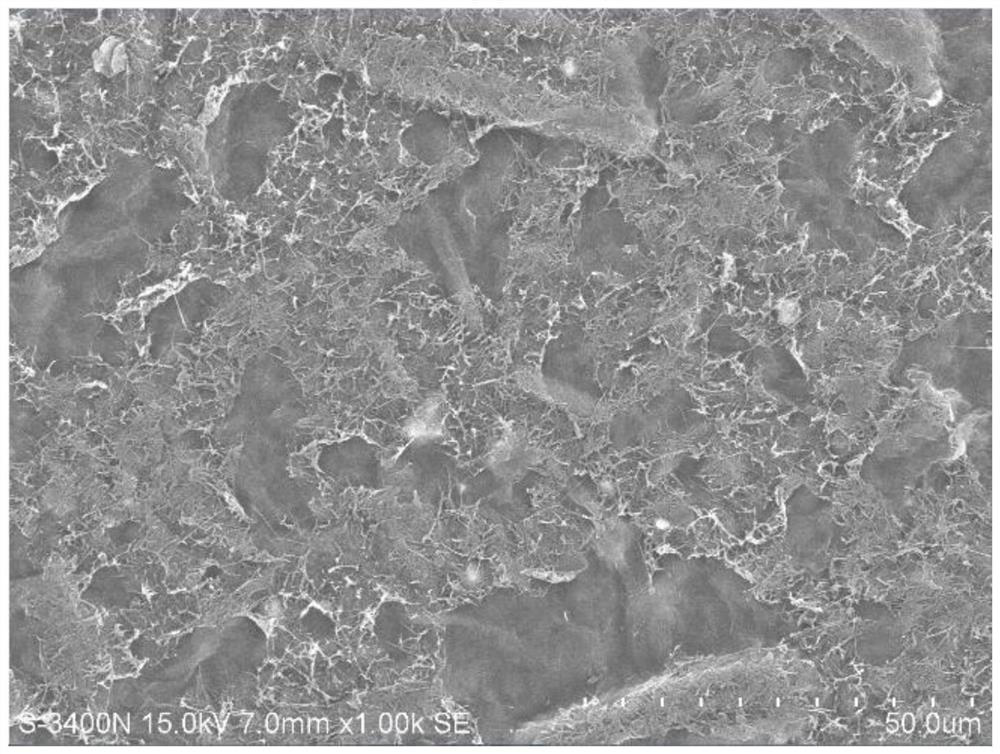

[0063] Step 3, take graphene, graphene oxide, nanocellulose of 0.35:0.325:0.325 mass ratio, namely graphene 3.5g, graphene oxide 3.25g, nanocellulose 3.25g, the graphene oxide that weighs, The nanocellulose was mixed and configured to form an aqueous dispersion with a concentration of 0.5 mg / ml, and a mixed system was obtained after ultrasonic dispersion for 50 min at a power of 800 W.

[0064] Step 4, using the weighed graphene to prepare a graphene aqueous dispersion with a conc...

Embodiment 3

[0071] Step 1. Select the substrate. After the substrate is dried by brushing the surfactant, spray paint on the surface of the substrate to form the first insulating layer. The coating amount is 100g / m 2 , and dried in a vacuum oven at 80°C for 5 hours.

[0072] Step 2: Adhere the copper foil to the insulating coating of the base to make electrodes; the distance and arrangement direction between the two electrodes are determined according to the effective heating area and the profile of the base.

[0073] Step 3, take graphene, graphene oxide, nanocellulose of 0.55:0.225:0.225 mass ratio, namely graphene 5.5g, graphene oxide 2.25g, nanocellulose 2.25g, the graphene oxide that weighs, The nanocellulose was mixed and configured to form an aqueous dispersion with a concentration of 0.5 mg / ml, and a mixed system was obtained after ultrasonic dispersion for 50 min at a power of 800 W.

[0074] Step 4, using the weighed graphene to prepare a graphene aqueous dispersion with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com