Ultrahigh-elasticity wire and preparation method thereof

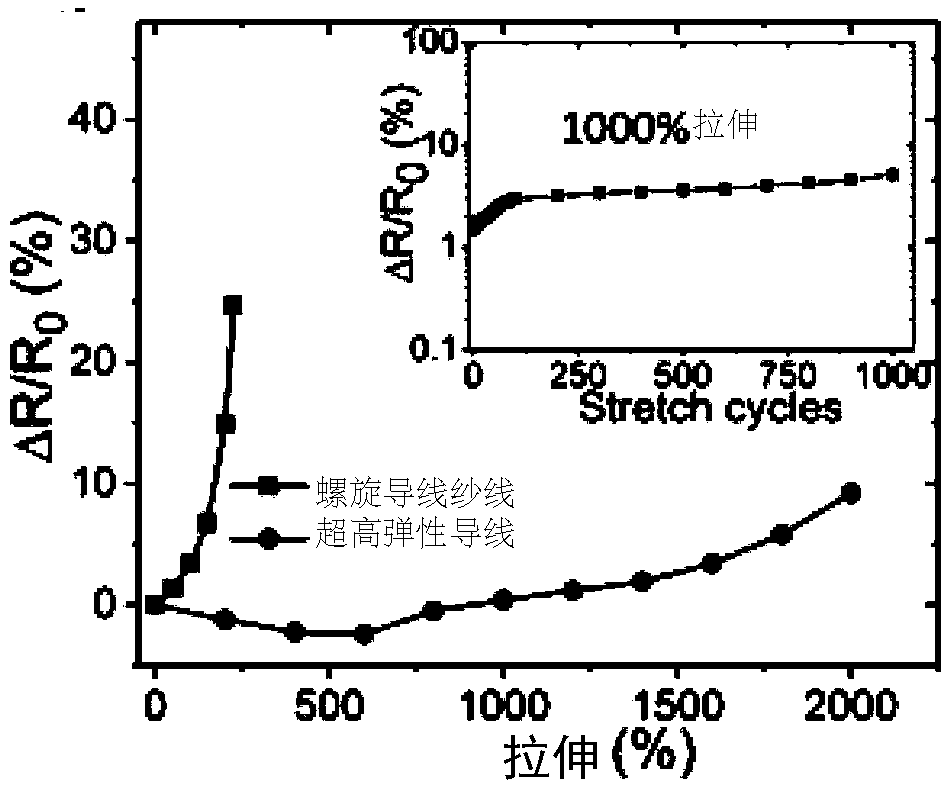

An elastic and wire technology, applied in the field of ultra-high elastic wire and its preparation, can solve the problems of increasing polymer hardness, affecting the elasticity of the polymer matrix, and being unsuitable for wearable electronics, etc., achieving small changes in conductance, novel preparation methods, excellent Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

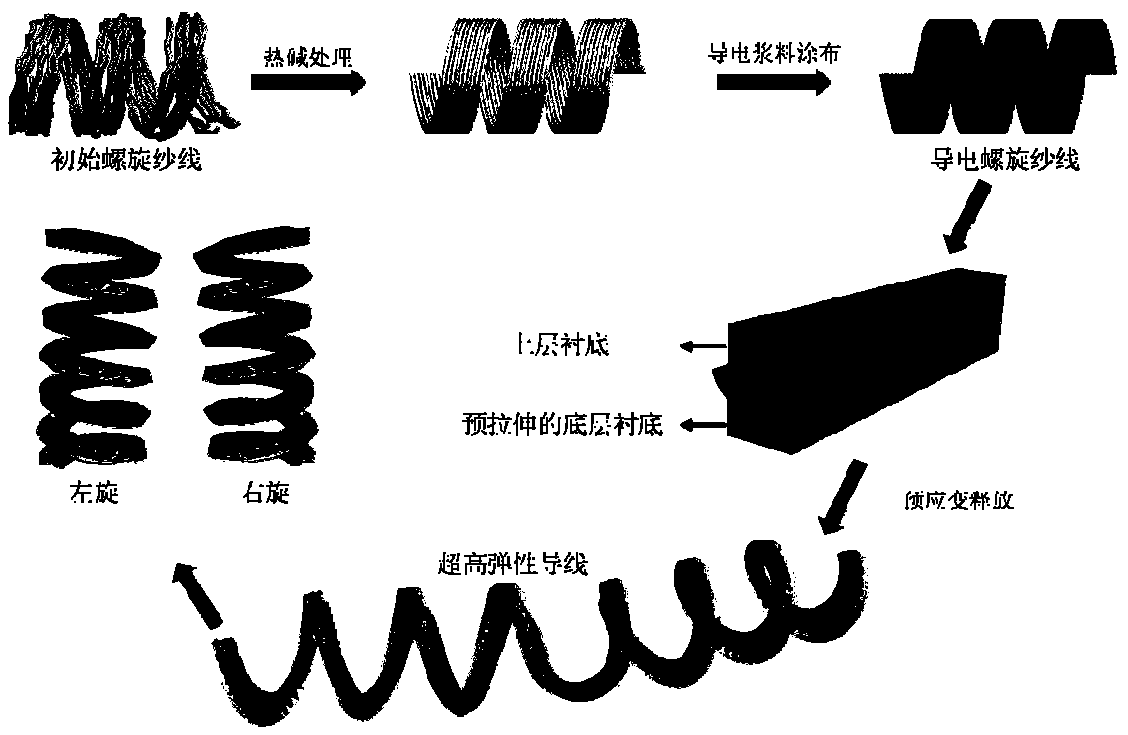

[0049] Preparation of flexible conductive fibers. In one embodiment of the present invention, the flexible conductive fiber includes yarns in a helical structure (helical yarns or initial helical yarns), and conductive materials adsorbed on the yarns. The preparation method includes: selecting yarns with good hygroscopicity and processing them into a helical structure, controlling the initial helical diameter between 5-1000 μm, so as to obtain helical yarns. Then dip the helical yarn in the conductive slurry, keep it for a certain period of time, take it out, dry it, and repeat it several times to obtain the conductive helical yarn (flexible conductive fiber) with a primary helical structure. Wherein, the conductive paste is a paste containing conductive materials (for example, conductive polymer ink or ink, etc.), and its concentration may be 0.01-50 mg / ml. The solvent of the conductive paste includes at least one of alcohol (eg, ethanol, etc.), water, toluene, etc., but doe...

Embodiment 1

[0055] A bundle of helical polyester yarns (initial helical diameter 100-1000 μm, cross-sectional diameter 5-500 μm) was treated with oxygen plasma (100 W, 10 min), and then silver nanowires (length 20- 30 μm, diameter 80-100nm) ethanol dispersion (add a small amount of PVP, wherein the mass ratio of PVP and silver nanowires is 3:1-1:3) and dip coating twice, and then use hydrogen plasma treatment (100W, 10min), Then it is adhered to the pre-stretched 30% strained ecoflex substrate, and the conductive yarn is completely embedded by dripping ecoflex, and then cured at 75 degrees for 30 minutes, and the substrate is released to obtain an ultra-high elastic wire. The initial helical diameter of the ultra-high elastic wire is about 5mm, the initial cross-sectional diameter is 100-1000μm, the stretchable range can reach 100 times the initial length, and the conductivity is 10 4 S / cm.

Embodiment 2

[0057] A bundle of helical polyester yarns (initial helix diameter 100-1000 μm, cross-sectional diameter 5-500 μm) was treated with oxygen plasma (100W, 10min), and then silver nanowires (length 20- 30 μm, diameter 80-100nm) ethanol dispersion (adding a small amount of PVP, wherein the mass ratio of PVP and silver nanowires is 3:1-1:3) dipped and coated 3 times, and then treated with hydrogen plasma (100W, 10min), Then it is adhered to the pre-stretched 30% strained ecoflex substrate, and the conductive yarn is completely embedded by dripping ecoflex, and then cured at 75 degrees for 30 minutes, and the substrate is released to obtain an ultra-high elastic wire. The initial helical diameter of the ultra-high elastic wire is about 5mm, the initial cross-sectional diameter is 100-1000μm, the stretchable range can reach 100 times the initial length, and the electrical conductivity is 6*10 4 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Spiral diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com