Intelligent printer work area air quality monitoring system based on machine learning

An intelligent monitoring system and air quality technology, applied in the direction of instruments, gas processing, measuring devices, etc., can solve the problems of high cost, large space occupation, poor processing effect, etc., to reduce energy consumption, reduce operating costs, and reduce the environment. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

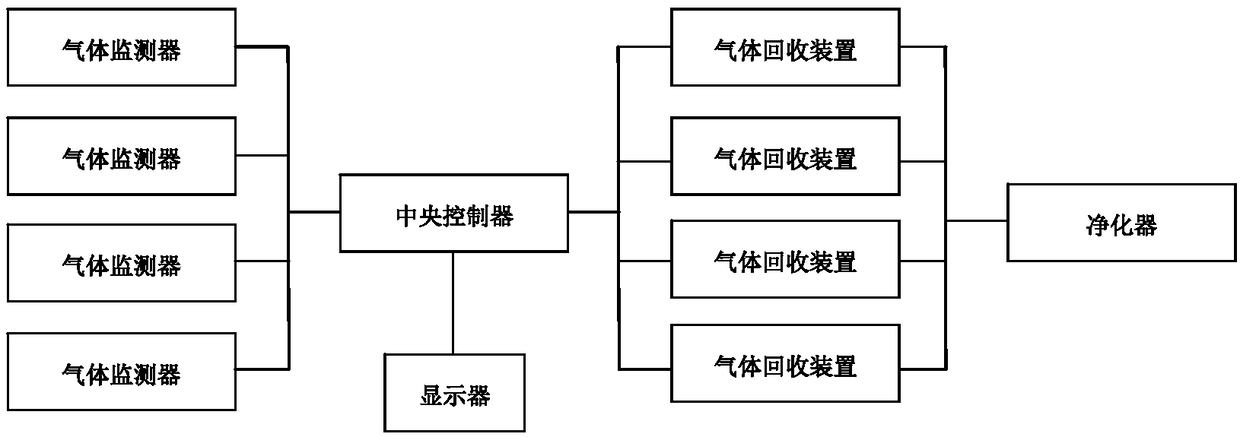

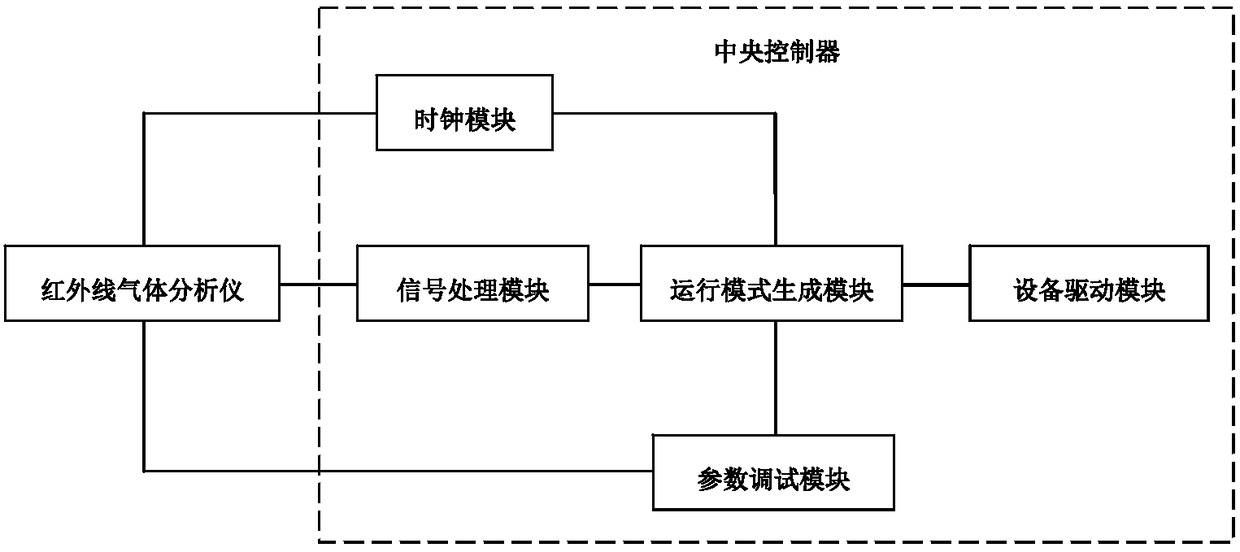

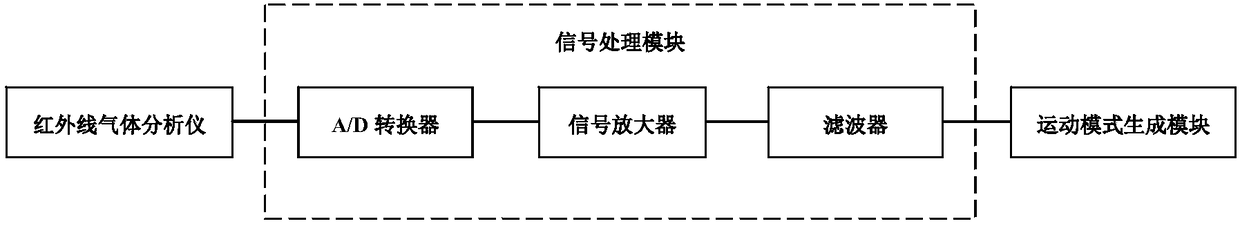

[0027] An intelligent monitoring system for air quality in the working area of a printing press according to the present invention will be described in detail below with reference to the drawings and embodiments.

[0028] The smell that most people can smell in the printing workshop is mainly the harmful gas emitted by volatile substances such as ink during the transfer, debugging and heating process, collectively referred to as VOC (volatile organic compounds). This kind of gas is very different from the air pollution PM 2.5 we often say. PM 2.5 is mainly particle pollution of a certain diameter, while VOC refers to gas pollution.

[0029]The most effective way to eliminate volatile organic substances is source treatment, that is, do not use or use as little as possible of inks and other coatings containing VOC components, such as using some water-based inks, inks containing plant-based inks or UV inks, these inks contain VOCs The ingredients are very small, even so, harmfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com