Chain-plate-type aluminum bar heating furnace

A heating furnace and chain plate type technology, applied in the field of chain plate type aluminum rod heating furnace, can solve the problems of complex structure of the push rod type aluminum rod heating furnace, high degree of automatic production, equipment failure, etc., and achieve simple structure and external interference. Small, well-set effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

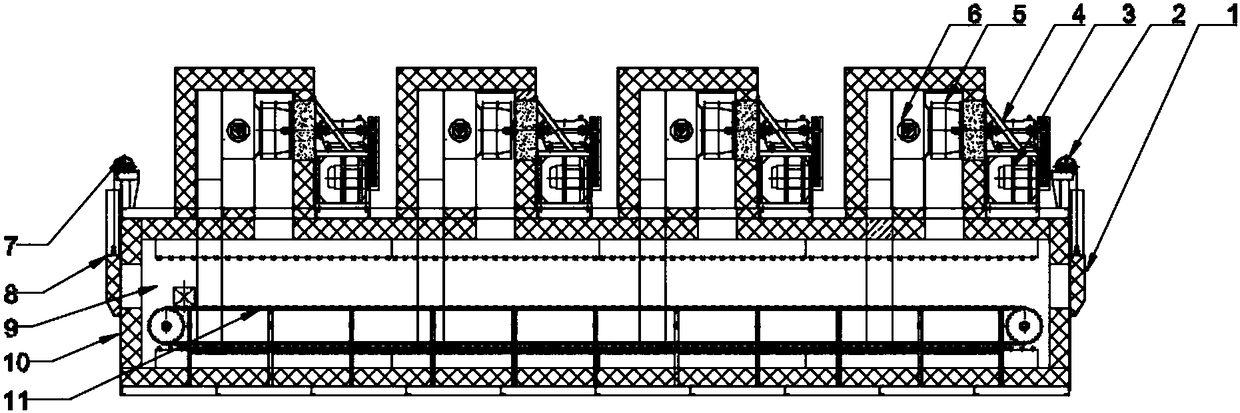

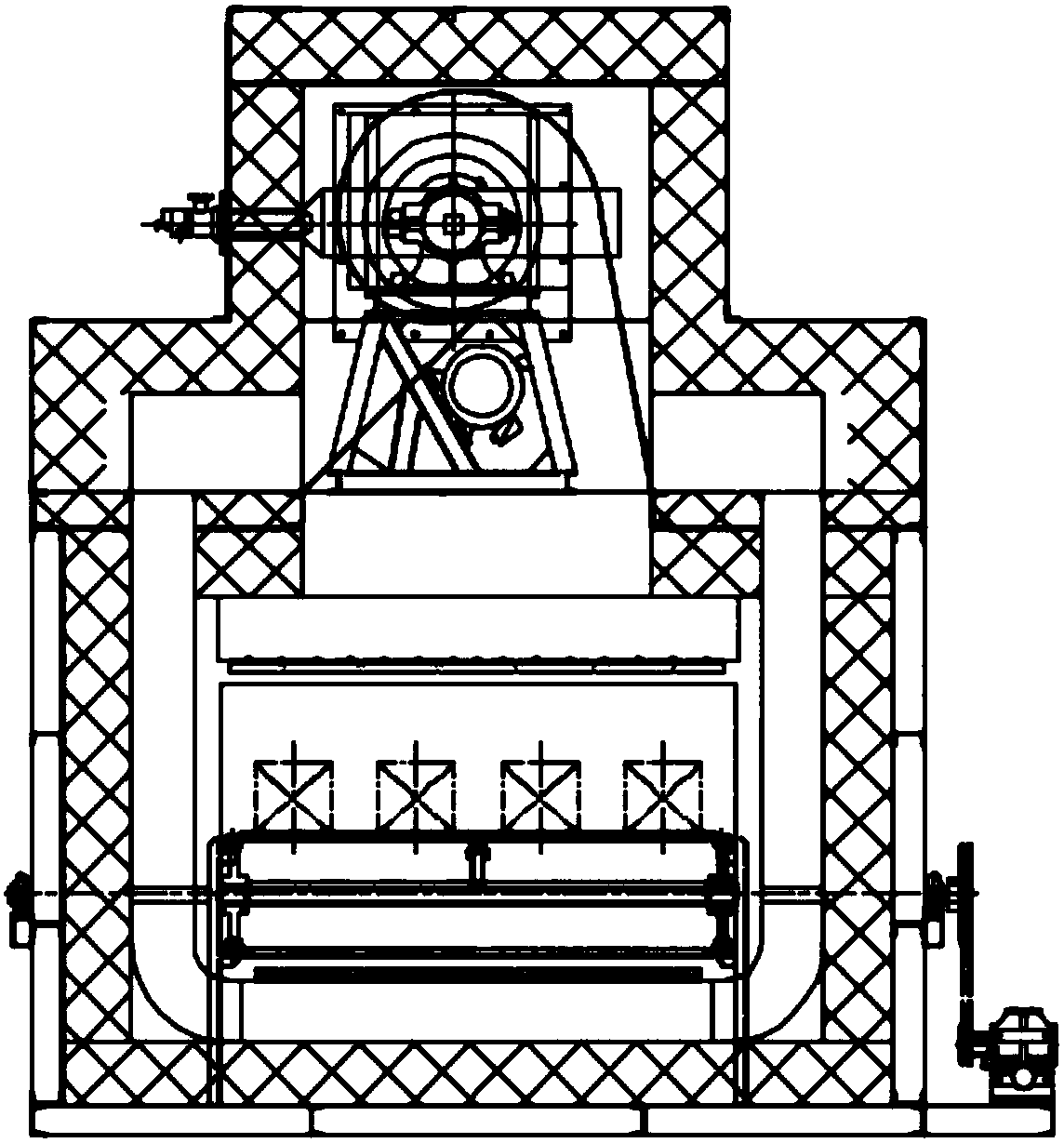

[0018] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

[0019] see as figure 1 —— figure 2 As shown, this specific embodiment adopts the following technical scheme: it includes a feed furnace door 1, a feed furnace door lifting mechanism 2, a circulating fan motor 3, a circulating fan reducer 4, a circulating fan 5, a burner 6, and a discharge furnace Door lifting mechanism 7, discharge furnace door 8, furnace 9, furnace wall 10, workpiece transmission chain plate 11; the two ends of the furnace 9 are respectively provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com