Low-speed machine multifunctional connecting rod bolt

A multi-functional, low-speed machine technology, applied in the directions of bolts, screws, nuts, etc., can solve the problem of inconvenient cleaning of oil pollution, and achieve the effects of good oil absorption performance, high oil absorption rate, and good anti-loosening and anti-skid performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

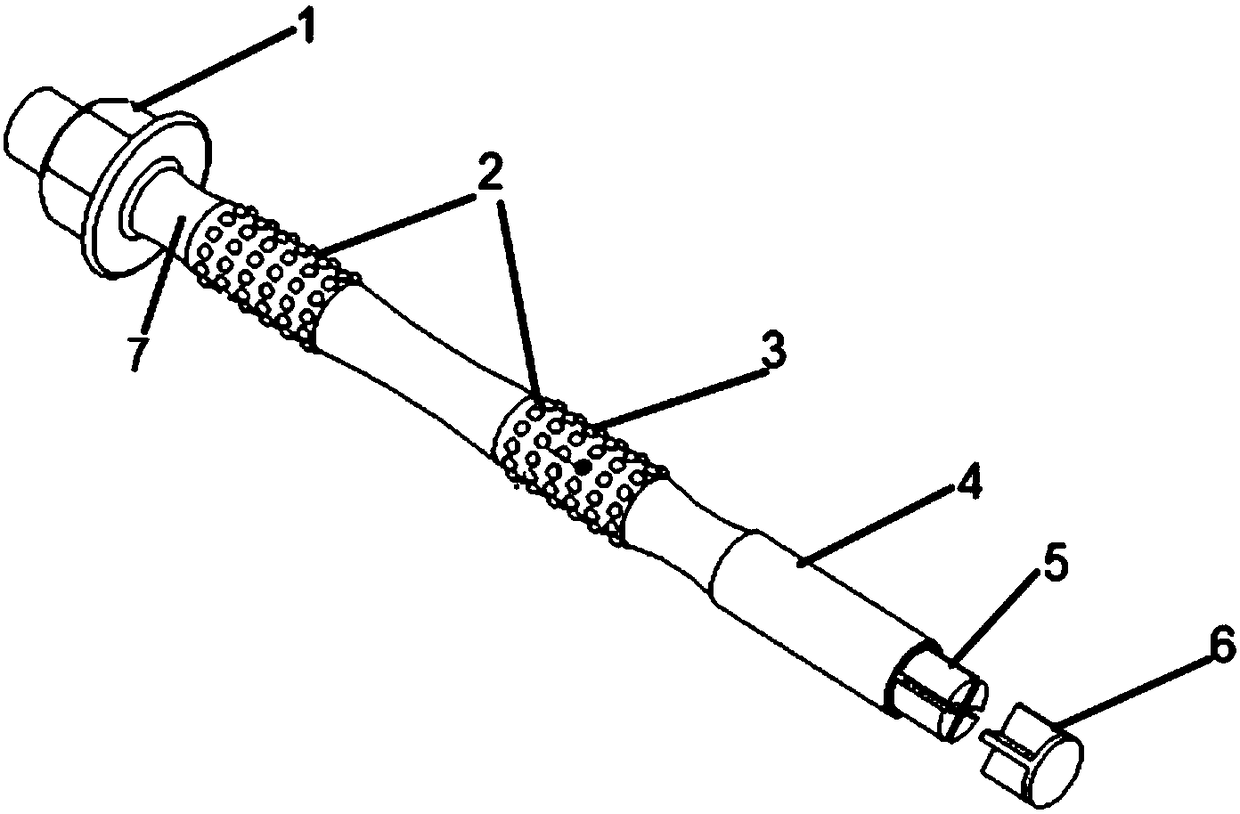

[0014] combine figure 1 , a low-speed machine multifunctional connecting rod bolt disclosed by the present invention, comprising a bolt head 1 and a screw rod 7, the bolt head 1 and the screw rod 7 are integrated, the bolt head 1 adopts a hexagonal head structure with a flange surface, and the screw rod 7 The upper and middle parts are two raised sections 2, and the lower part of the screw is a threaded section 4; the bolt head 1 in the bolt and the two raised sections in the upper and middle part of the screw 7 of the screw are arranged with six rows of circular particles for positioning 3. These protrusions are made of rubber, and then put on the protrusion section. The joint of the bolt head 1 of the screw rod and the screw rod 7 has rounded corners. There is a cross oil suction groove 5 under the thread section 4, and the cross oil suction groove 5 is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com