Integrated axial-suspension permanent-magnet synchronous shielding pump

A permanent magnet synchronous and shielded pump technology, which is applied to components, pumps, and pump devices of elastic fluid pumping devices, and can solve thrust bearing wear, rotor axial force that is difficult to fully balance, and high eddy current loss And other problems, to achieve high reliability, avoid eddy current loss, reduce the effect of calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

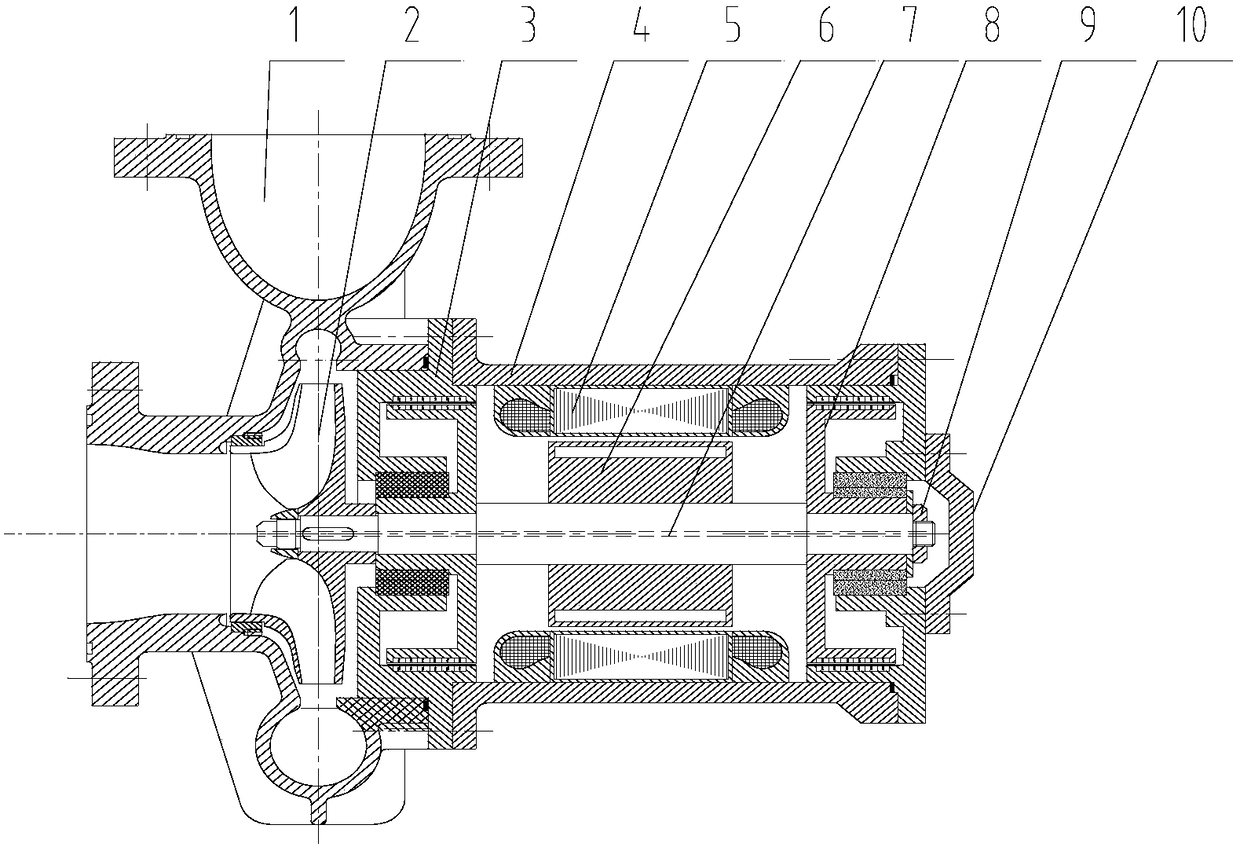

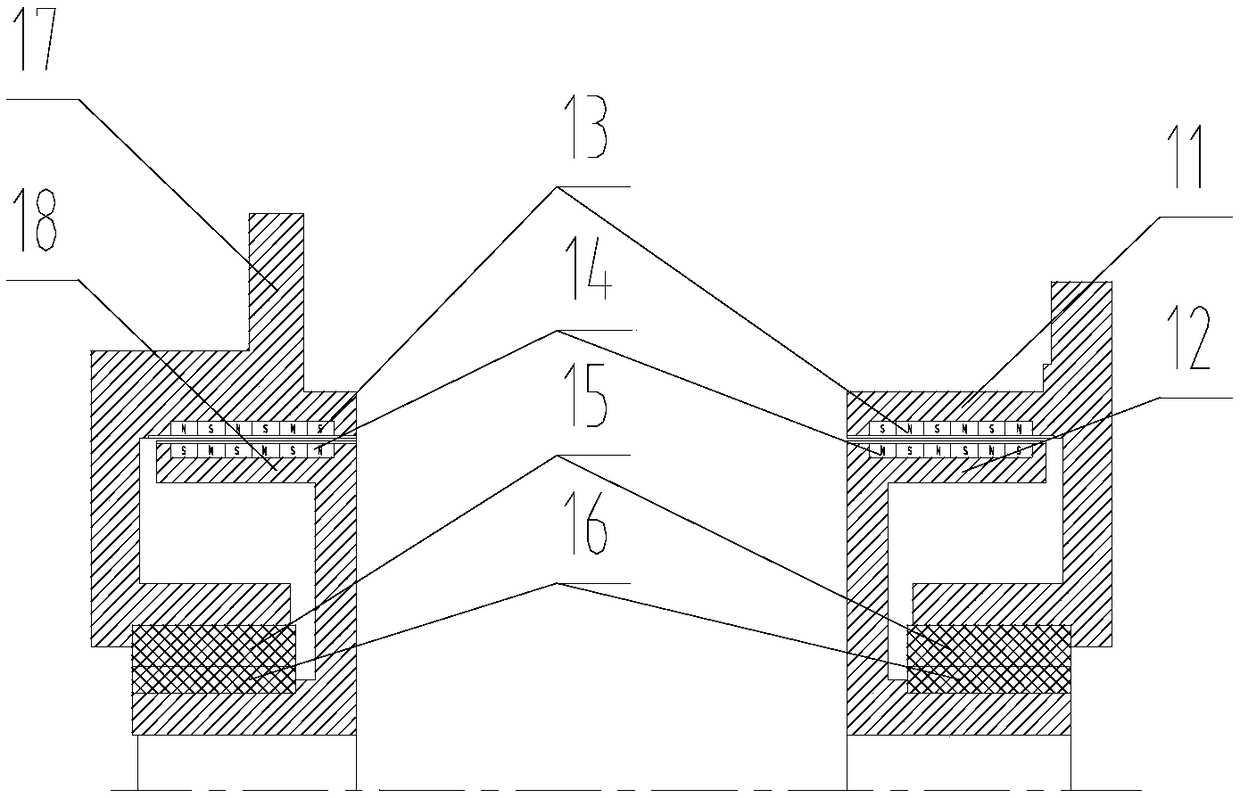

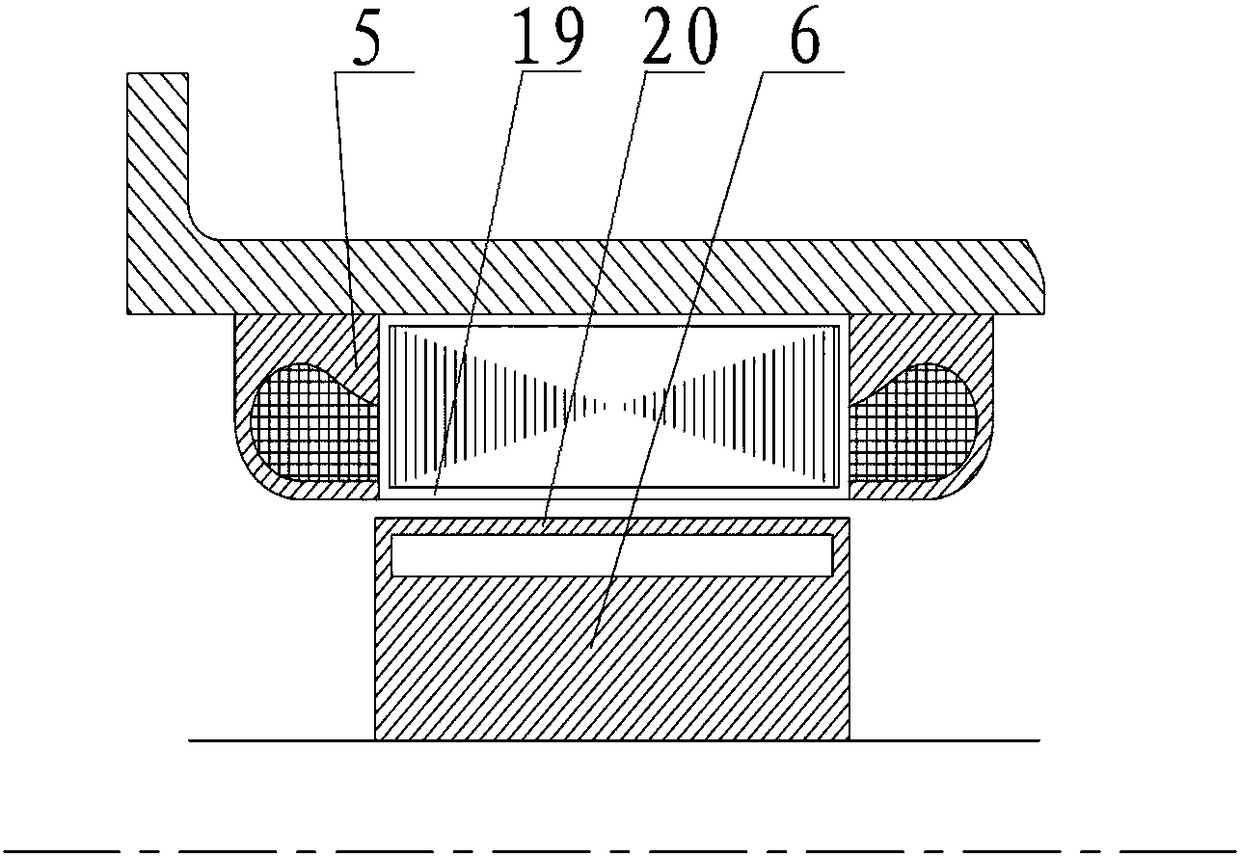

[0029] Such as figure 1 , figure 2 As shown, an integrated axial suspension permanent magnet synchronous canned pump includes a pump body 1, an impeller 2 and a permanent magnet canned motor. The permanent magnet shielded motor includes a front axial suspension bearing device 3 , a motor casing 4 , a winding stator 5 , a permanent magnet rotor 6 , a pump shaft 7 and a rear axial suspension bearing device 8 . The pump body 1 is installed on the motor casing 4 through the front axial suspension bearing device 3 , and the pump shaft 7 passes through the impeller 2 , the front axial suspension bearing device 3 and the rear axial suspension bearing device 8 in sequence. The head of the pump shaft 7 is fixed to the impeller 2 through a locking component, and is tightly connected to the front axial suspension be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com