STP ultra-thin vacuum heat insulation plate for building external wall and preparation method thereof

A technology of vacuum insulation panels and building exterior walls, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of large thickness of insulation layer, reduce insulation effect, increase wall self-weight, etc., achieve good insulation performance, reduce labor costs, etc. The effect of using strength and construction technology is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

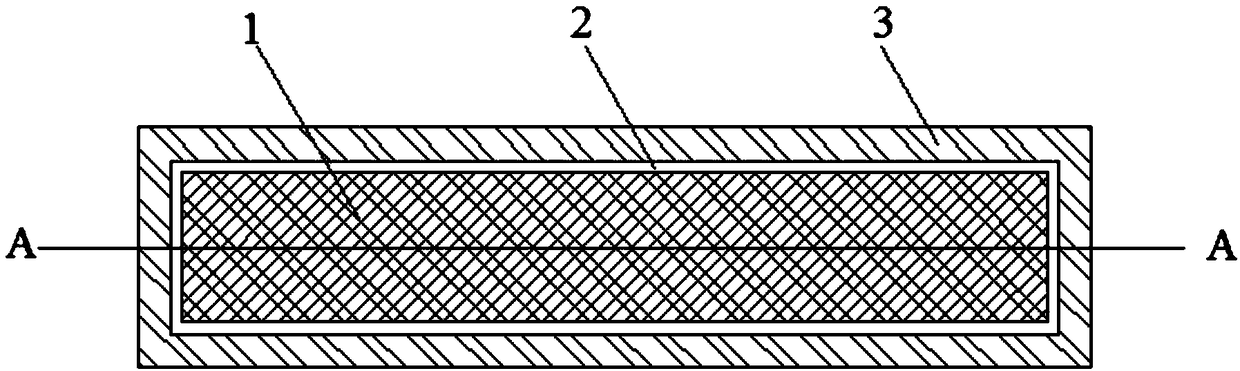

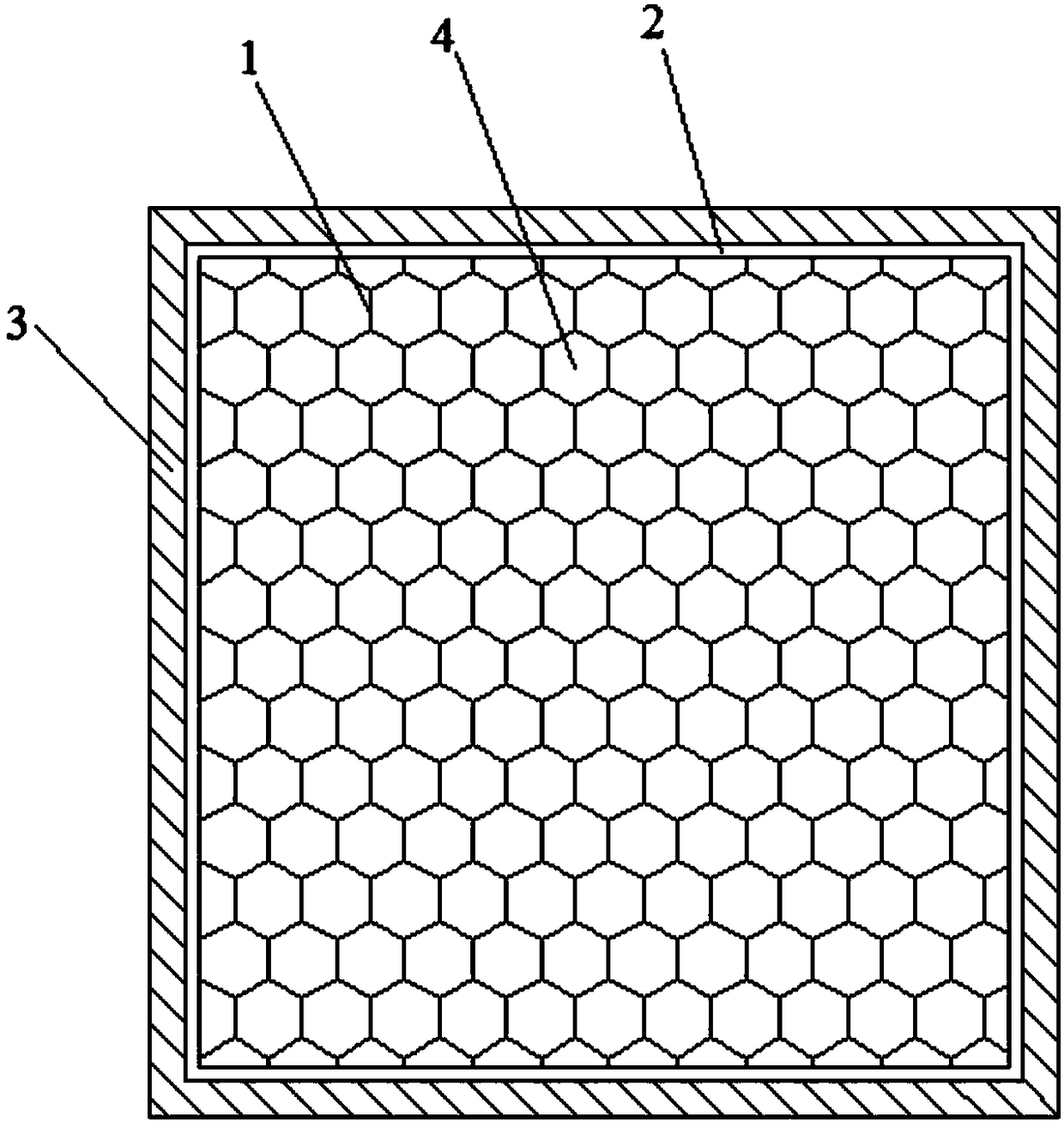

[0030] STP ultra-thin vacuum insulation panels for building exterior walls, including composite inorganic fiber core material 1, insulating conductive heat insulating coating 2 and high barrier composite film 3; insulating conductive heat insulating coating 2 coated on composite inorganic fiber core material 1 On the outer surface, the composite inorganic fiber core material 1 is arranged in the high-barrier composite film 3, and the composite inorganic fiber core material 1 is provided with honeycomb-shaped through-holes 4, and the honeycomb-shaped through-holes 4 are filled with vitrified microbeads, and the honeycomb-shaped through-holes 4 are Inclined hole with an inclination angle of 30°. Wherein, the composite inorganic fiber core material 1 includes glass fiber, inorganic mineral ultrafine powder, silicon dioxide micropowder, and lightweight heat-insulating material with a weight ratio of 3:4:2:1. , It has been proved by experiments that its thermal conductivity is belo...

Embodiment 2

[0032]STP ultra-thin vacuum insulation panels for building exterior walls, including composite inorganic fiber core material 1, insulating conductive heat insulating coating 2 and high barrier composite film 3; insulating conductive heat insulating coating 2 coated on composite inorganic fiber core material 1 On the outer surface, the composite inorganic fiber core material 1 is arranged in the high-barrier composite film 3, and the composite inorganic fiber core material 1 is provided with honeycomb-shaped through-holes 4, and the honeycomb-shaped through-holes 4 are filled with vitrified microbeads, and the honeycomb-shaped through-holes 4 are Inclined hole with an inclination angle of 40°. The core material of the STP ultra-thin vacuum insulation panel is coated with a thermal insulation coating, so that it has a super heat insulation effect, and at the same time, a honeycomb-shaped inclined through hole is set on the thermal insulation panel, which can ensure the stability ...

Embodiment 3

[0036] STP ultra-thin vacuum insulation panels for building exterior walls, including composite inorganic fiber core material 1, insulating conductive heat insulating coating 2 and high barrier composite film 3; insulating conductive heat insulating coating 2 coated on composite inorganic fiber core material 1 On the outer surface, the composite inorganic fiber core material 1 is arranged in the high-barrier composite film 3, and the composite inorganic fiber core material 1 is provided with honeycomb-shaped through-holes 4, and the honeycomb-shaped through-holes 4 are filled with vitrified microbeads, and the honeycomb-shaped through-holes 4 are Inclined hole with an inclination angle of 45°. The core material of the STP ultra-thin vacuum insulation panel is coated with a thermal insulation coating, so that it has a super heat insulation effect, and at the same time, a honeycomb-shaped inclined through hole is set on the thermal insulation panel, which can ensure the stability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com