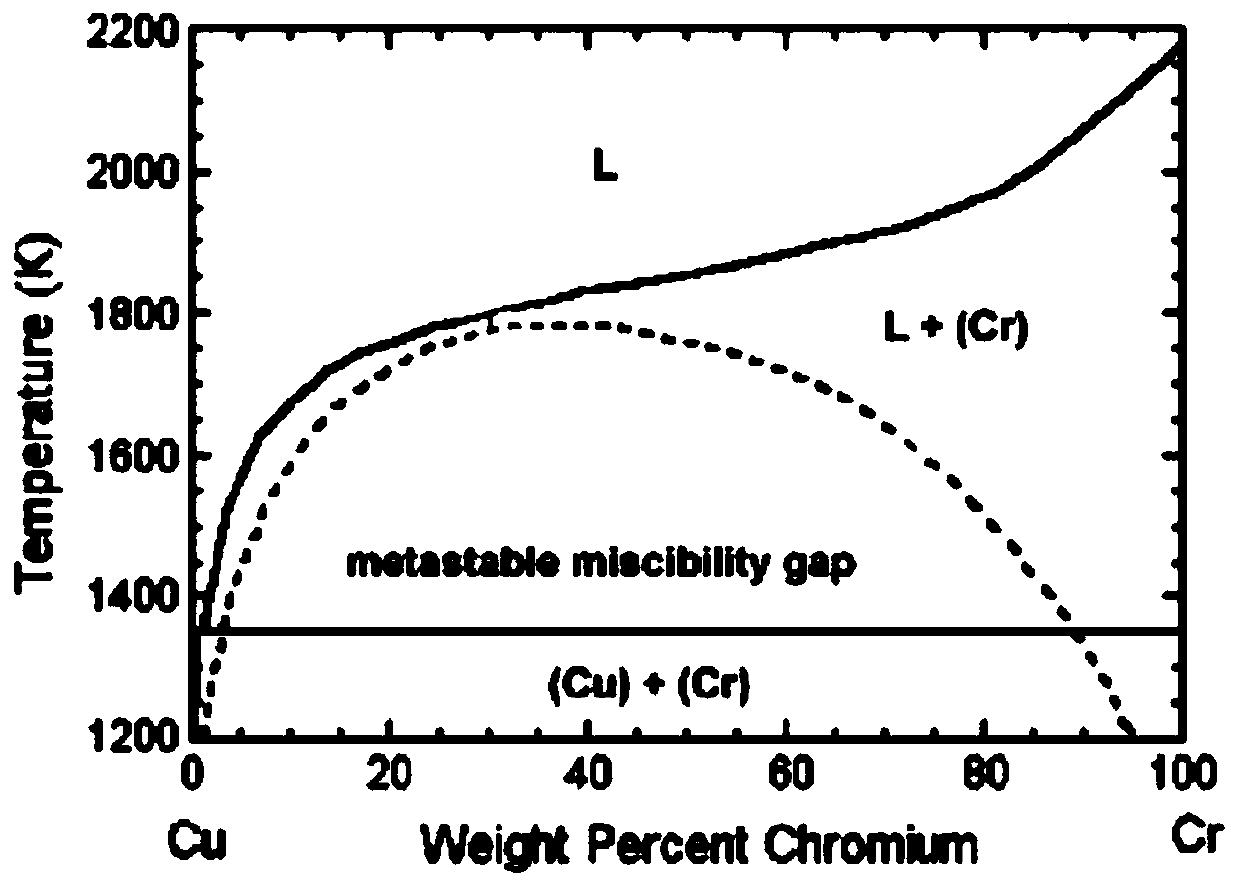

Cu-cr alloy containing trace pb element and solidification preparation method thereof

A cu-cr and alloy technology, applied in the field of Cu-Cr alloy preparation, can solve the problems of two-phase delamination, limitation of industrial preparation and application, phase segregation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Such as figure 2 As shown, a Cu-15wt%Cr alloy is cast using a copper mold, the inner diameter of the copper mold is 5mm, and the temperature of the copper mold is room temperature before casting. The Cr-rich phase exists in the form of coarse dendrites in the sample without adding Pb, and the Cr-rich phase exists in the form of dispersed particles in the alloy sample added with 0.1wt% Pb, and the distribution is uniform.

[0022] Its preparation process is as follows:

[0023] The Cu-15wt%Cr alloy and the Cu-15wt%Cr-0.1wt%Pb alloy were smelted in an electric arc furnace, the temperature was raised to 1600°C and kept for 2 minutes, and then the melt was poured into a copper mold.

Embodiment 2

[0025] Such as image 3 As shown, a Cu-20wt%Cr alloy is casted with a copper mold, the inner diameter of the copper mold is 5mm, and the temperature of the copper mold is room temperature before casting. The Cr-rich phase exists in the form of coarse dendrites in the sample without adding Pb, and the Cr-rich phase exists in the form of dispersed particles in the alloy sample with 0.07wt% Pb added, and the distribution is uniform.

[0026] Its preparation process is as follows:

[0027] The Cu-20wt%Cr alloy and the Cu-20wt%Cr-0.07wt%Pb alloy were smelted in an electric arc furnace, the temperature was raised to 1600°C and kept for 2 minutes, and then the melt was poured into the copper mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com