Production method and application of soil heavy metal compound pollution eluting agent

A production method and composite pollution technology, applied in the restoration, application, soil conditioning materials and other directions of polluted soil, can solve problems such as high cost, secondary pollution, incomplete clarity, etc., achieve high speed, reduce harmful substance residues, The effect of simple and easy technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

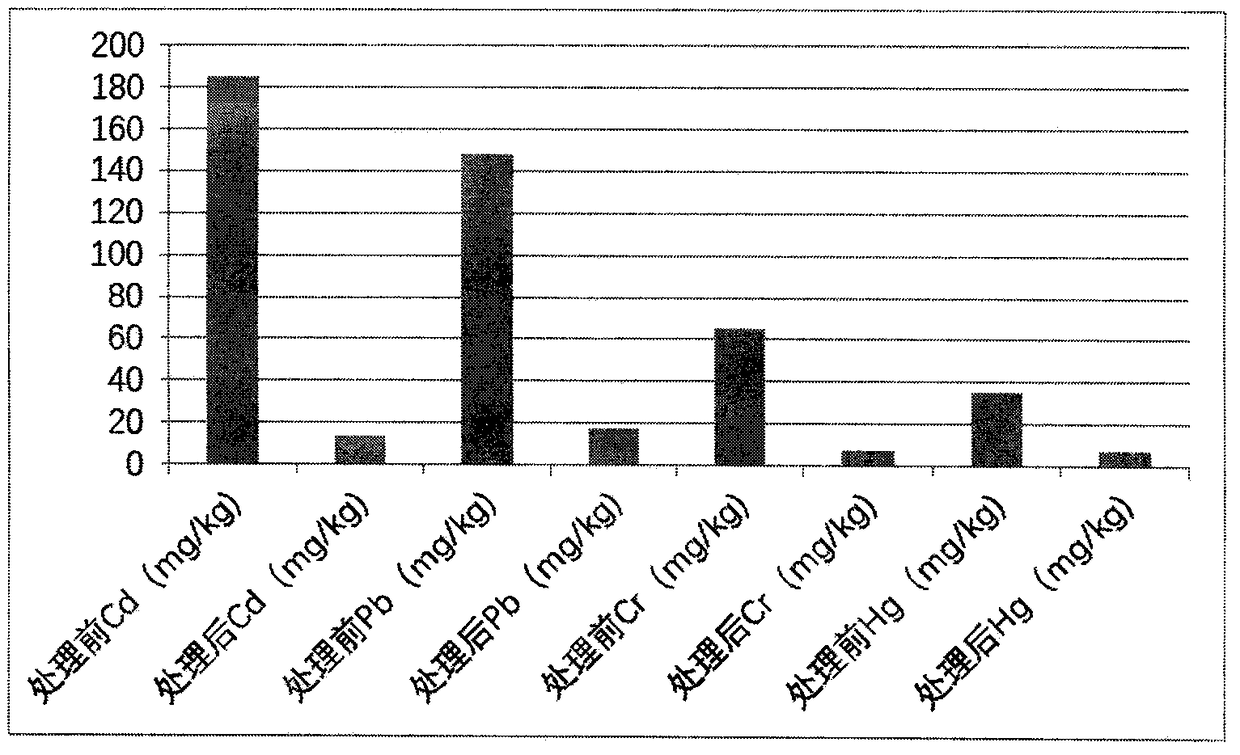

Image

Examples

Embodiment 1

[0028] 1. Add 1,000-20,000 grams of sodium diacetamide tetraacetate, 500 grams of bis-1,6-hexamethylene triamine pentamethylene phosphonic acid, and 500 grams of sodium citrate in 50 liters of distilled water, slowly heat to dissolve, slowly Stir, add 500 grams of maleic acid-acrylic acid copolymer, 500 grams of sodium silicate, and 1000 grams of sodium pyrophosphate after all are dissolved, stir slowly, after most of them dissolve, after cooling, add 200 milliliters of concentrated hydrochloric acid, and stir evenly.

[0029] 2. Add 2000 ml of the product treated in the above 1 to a soil column containing 50 kg of soil to dissolve and elute the heavy metals in the soil column. Before adding the above mixed eluent, add 6000 ml to the soil column Use distilled water to fully moisten the soil column, and make the soil particles and voids in the soil column evenly distributed without large holes.

[0030]3. Slowly add 2000 ml of the mixed eluent prepared in the above 1 to the soi...

Embodiment 2

[0032] 1. In 50 liters of distilled water, add 10,000 grams of sodium diacetamide tetraacetate, 800 grams of bis-1,6-hexamethylene triamine pentamethylene phosphonic acid, and 1,500 grams of sodium citrate, slowly heat to dissolve, and stir slowly. Add 1500 grams of maleic acid-acrylic acid copolymer, 1000 grams of sodium silicate, and 2000 grams of sodium pyrophosphate after they are completely dissolved, and stir slowly.

[0033] 2. Add 3000 ml of the product treated in the above 1 to a soil column containing 50 kg of soil to dissolve and elute the heavy metals in the soil column. Before adding the above mixed eluent, add 15000 ml to the soil column Use distilled water to fully moisten the soil column, and make the soil particles and voids in the soil column evenly distributed without large holes.

[0034] 3. Slowly add 3000 ml of the mixed eluent prepared in the above 1 to the soil column after the above 2 treatment in batches, place a collector under the soil column to col...

Embodiment 3

[0036] 1. Add 20,000 grams of sodium diacetamide tetraacetate, 1,500 grams of bis-1,6-hexamethylenetriaminepentamethylene phosphonic acid, and 2,500 grams of sodium citrate into 50 liters of distilled water, slowly heat to dissolve, and stir slowly. Add 3,500 grams of maleic acid-acrylic acid copolymer, 2,000 grams of sodium silicate, and 3,000 grams of sodium pyrophosphate after they are completely dissolved, and stir slowly.

[0037] 2. Add 5000 ml of the product treated in the above 1 to the soil column containing 50 kg of soil, dissolve and elute the heavy metals in the soil column, and add 25000 ml to the soil column before adding the above mixed eluent Use distilled water to fully moisten the soil column, and make the soil particles and voids in the soil column evenly distributed without large holes.

[0038] 3. Slowly add 4000 ml of the mixed eluent prepared in the above 1 to the soil column after the above 2 treatment in batches, place a collector under the soil column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com