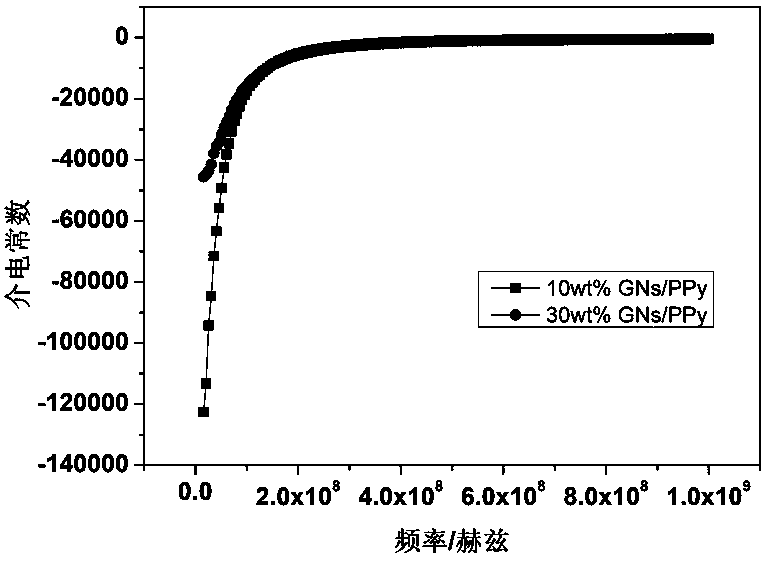

Preparation method of graphene/polypyrrole nanoparticle with negative dielectric constant

A negative dielectric constant, pyrrole nanotechnology, applied in the field of graphene/polypyrrole nanoparticle preparation, can solve problems such as difficulty in achieving negative dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The present embodiment is a kind of preparation method of the graphene / polypyrrole nanoparticle with negative dielectric constant, carries out according to the following steps:

[0017] (1) Preparation of dispersion A: Weigh 0.1 mol of hydrochloric acid, 0.06 mol of potassium dichromate and 10% graphene, and add them into 300 ml of water. Ultrasonic dispersion for 50 minutes (power 320W) to fully disperse the oxidant, protonic acid and graphene in water.

[0018] (2) Preparation of dispersion B: 0.08 mol of pyrrole (Py) dispersed in 60 ml of water, Py dispersion in ice-water mixture, ultrasonic 50 min, power 320W.

[0019] (3) Preparation of graphene / polypyrrole nanoparticles: the dispersion A was placed in the ice-water mixture contained in the crystallization dish, and the crystallization dish was placed on a magnetic stirrer stirring at a speed of 900 r / min. When the temperature of the dispersion is lower than 10°C, add the dispersion B dropwise while ...

Embodiment 2

[0024] Embodiment 2: The present embodiment is a kind of preparation method of the graphene / polypyrrole nanoparticle with negative dielectric constant, carries out according to the following steps:

[0025] (1) Preparation of dispersion A: Weigh 0.1 mol of salicylic acid, 0.06 mol of ferric chloride and 30% graphene, and add to 300 ml of water. Ultrasonic dispersion for 50min (power 320W) to fully disperse ferric chloride, tartaric acid and graphene in water.

[0026] (2) Preparation of dispersion B: 0.08 mol of pyrrole (Py) dispersed in 60 ml of water, Py dispersion in ice-water mixture, ultrasonic 50 min, power 320W.

[0027] (3) Preparation of graphene / polypyrrole nanoparticles: the dispersion A was placed in the ice-water mixture contained in the crystallization dish, and the crystallization dish was placed on a magnetic stirrer stirring at a speed of 900 r / min. When the temperature of the dispersion is lower than 10°C, add the dispersion B dropwise while stirring, and 60...

Embodiment 3

[0032] Embodiment 3: The present embodiment is a kind of preparation method of the graphene / polypyrrole nanoparticle with negative dielectric constant, carries out according to the following steps:

[0033] (1) Preparation of dispersion A: Weigh 0.1 mol of p-toluenesulfonic acid, 0.06 mol of potassium dichromate and 50% graphene, and add to 300 ml of water. Ultrasonic dispersion for 50 minutes (power 320W) to fully disperse the oxidant, protonic acid and graphene in water.

[0034] (2) Preparation of dispersion B: 0.08 mol of pyrrole (Py) dispersed in 60 ml of water, Py dispersion in ice-water mixture, ultrasonic 50 min, power 320W.

[0035] (3) Preparation of graphene / polypyrrole nanoparticles: the dispersion A was placed in the ice-water mixture contained in the crystallization dish, and the crystallization dish was placed on a magnetic stirrer stirring at a speed of 800 r / min. When the temperature of the dispersion is lower than 10°C, add the dispersion B dropwise while st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com