Square steel pipe cold-drawing repairing device and method

A square steel pipe and a technology to be repaired, applied in the field of steel pipe repair, and can solve the problems of material damage, changes in the mechanical properties of steel pipes in the weld area, and difficulty in correcting and repairing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

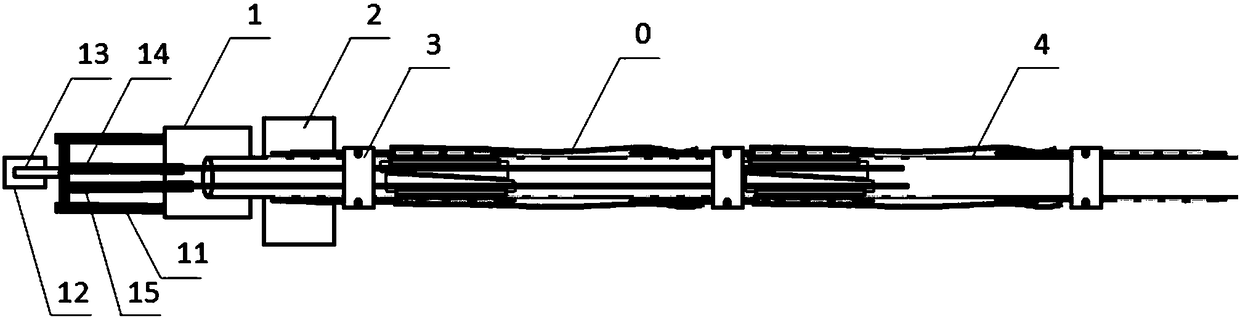

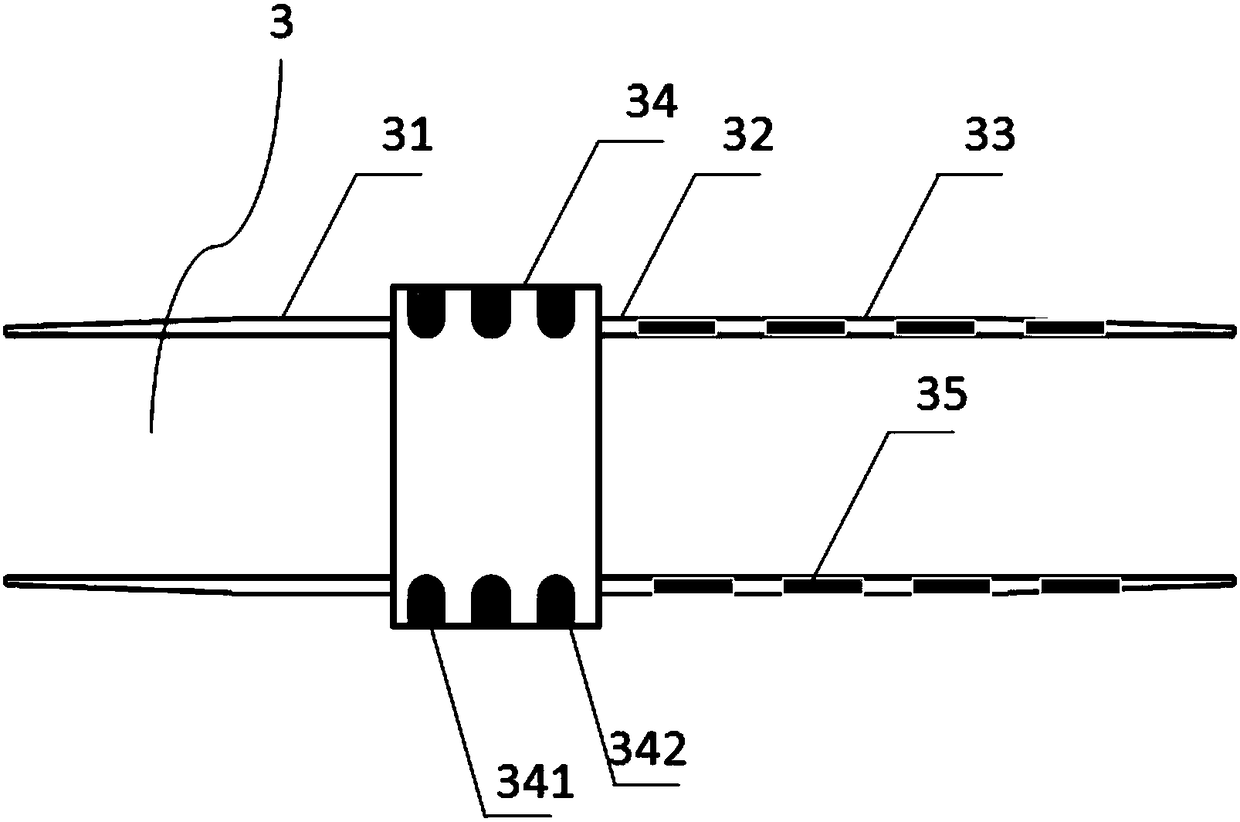

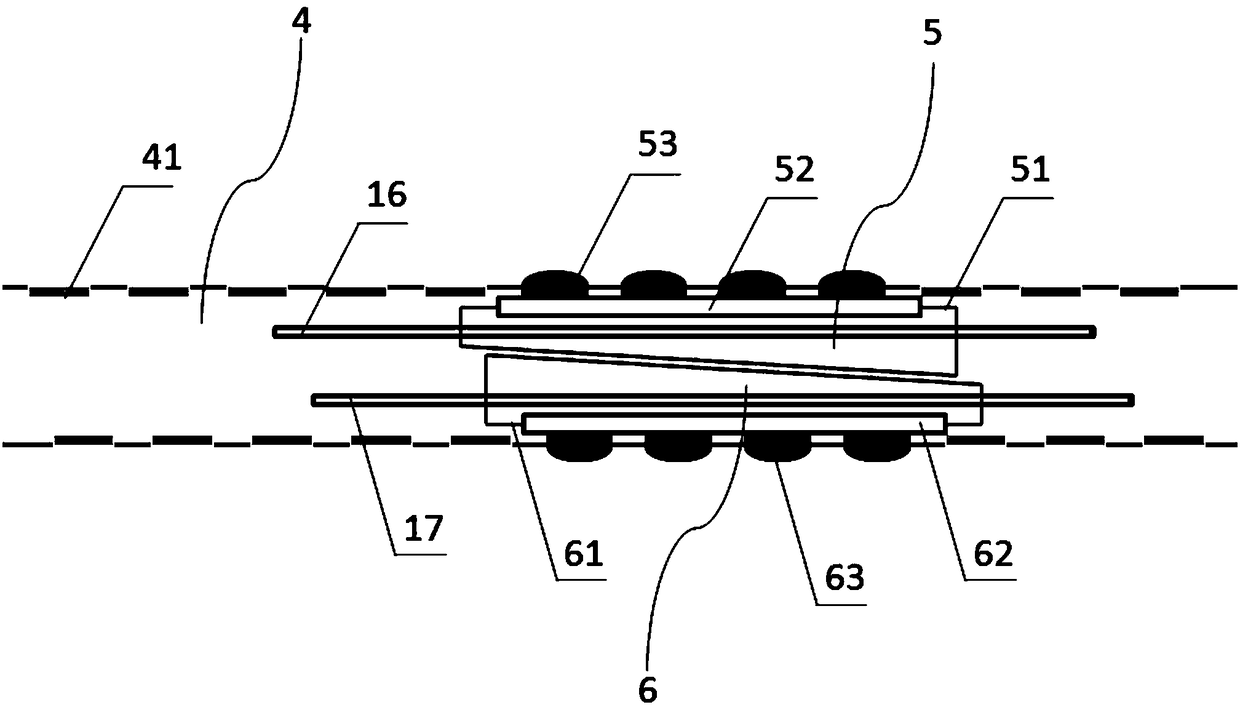

[0032] This embodiment provides a cold-drawn repair device for square steel pipes, such as Figure 1-Figure 3 As shown, the cold-drawn square steel pipe repair device includes: clamp 1, mold base 2, outer mold and hollow tie rod 4, characterized in that it also includes a plurality of connecting sleeves 3, the cross-sectional shape of the connecting sleeve 3 is square, the connecting sleeve 3 includes a guide section 31, a positioning section 32, and a locking section 33. The positioning section 32 is arranged in the middle of the connecting sleeve 3. The guide section 31 and the locking section 33 are respectively arranged on both sides of the positioning section 32. A positioning through hole (not shown) is provided on the side, a positioning frame 34 is sleeved on the positioning section 32, and positioning components are provided on the upper and lower sides of the positioning frame 34. The positioning components are matched with the positioning through holes to lock the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com